Induction PCBs

Induction PCBs optimize energy storage and signal control with components like coils and transformers, central to electronics across various applications.

With the rapid development of electronics, inductance is an indispensable phenomenon, playing a significant role in electronic system design and functionality. Similar to capacitance and resistance, inductance is an intrinsic electrical parameter. Induction PCBs are a cutting-edge application of this phenomenon, which forms the basis of most technologies.

Basics of Induction PCBs

An Induction PCB is particularly made to include electronic components such as coils, chokes, inductors, and transformers. These types of components are crucial in most circuits and applications with core presence variances and materials. Understanding these components and their diverse arrangements is central to having a complete idea of what happens in electronic and electrical systems.

The primary function of an Induction PCB is to store energy in the form of magnetic fields developed by running currents. The storage method, inductance, is to build a magnetic field that resists a change in current flow, thereby creating an induced voltage. Essentially, Induction PCBs manage two types of inductance: self-inductance, affecting a solitary circuit, and mutual inductance, affecting linked circuits through a shared magnetic field.

Building Induction PCBs

Induction PCBs are constructed using copper wires coiled around a core material and insulated. The core may be a non-magnetic plastic or a ferromagnetic material, depending on the magnetic requirements of a particular application. Slick procedures like area-product and Hanna curves are typically integrated into the design to maximize performance and efficiency.

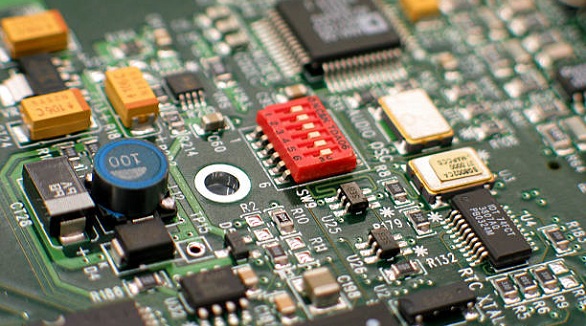

Induction PCBs can incorporate several types of inductors, each with its own benefits:

Iron Core Inductors: They are high power-to-inductance ratio, low-profile inductors whose application with high-frequency currents is restricted to a certain extent. They find common application in audio devices due to their highly effective performance in low-frequency environments.

Air Core Inductors: Air core inductors are the ideal choice where there is a minimum requirement of inductance. As they lack a physical core, they have zero core loss, although they use more wire turns than core-based inductors.

Iron Powder Inductors: They use an iron oxide core comprising fine insulating particles and also incorporate an air gap, which allows high magnetic flux storage. Generally used in switching power supplies, they possess relatively low permeability.

Ferrite Core Inductors: Ferrite core inductors are universal, with soft ferrites inherently being capable of polarity reversal and hard ferrites functioning as permanent magnets. The type of ferrite is chosen depending on the requirements of the application, particularly in electronics where specific magnetic properties are required.

Induction PCB Functions

Induction PCBs serve for two primary functions in electronic circuits:

Signal Control:

Induction PCBs are necessary for signal frequency control. By blocking the flow of alternating current (AC) and allowing direct current (DC) to pass through, they act as LC filters, isolating specific frequencies for advanced signal processing.

Energy Storage:

The coils' induced magnetic fields store energy, useful in devices that have effective control of energy. This aspect is more pronounced in computer circuits that have switchable power supplies, where the flow and storage of energy need to be carefully managed.

Applications of Induction PCBs

Induction PCBs form a core part of several applications, ranging from signal tuning to facilitating sophisticated sensor systems:

Fine-Tuning Circuits: Used in radios and televisions, Induction PCBs supply the accurate frequency tuning and alignment that allow devices to select and retain desired frequencies effectively.

Sensor Systems: Inductive proximity sensors utilize the magnetic fields of Induction PCBs to provide high operation reliability. Sensors are used in different applications such as traffic systems where they sense density without touching.

Induction Motors: In motors, magnetic fields are developed using AC current to cause the rotation of motor shafts. Induction PCBs regulate the speed of such motors, enhancing control and efficiency in motor-based systems.

Transformers: By incorporating several inductors into an Induction PCB, transformers are able to effectively manage levels of power transmission. This is important in power supplies where step-up and step-down transmissions are necessary to transmit energy effectively.

Filters: Combination of inductors and capacitors, Induction PCBs serve as filters that regulate the frequency of electrical signals into circuits. This purpose is crucial in guaranteeing system stability and efficiency.

At PCBX, we value how Induction PCBs leverage innovation and strategic engineering in electronics. Regardless of the potential expense—thanks to the premium iron and copper being used—use in telecom, power supplies, and radio technology makes them well worth the investment. The ability of Induction PCBs to effectively manage signal control and energy storage ensures that they will be central in shaping electronic technologies. As these technologies advance, skill design and implementation in Induction PCBs will be at the forefront of addressing future challenges and taking advantage of opportunities in electronics. The increasing use of these components in next-generation applications is a testament to their ever-lasting relevance and multifaceted nature in modern electronics.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Remote control circuits enable convenient, wireless device management using transmitters and receivers, with versatile applications in electronics and automation.

DIP switches, cost-effective and manual, enable easy configuration of device modes, offering flexibility and simplicity for various electronic applications.

High-frequency PCBs are crucial for fast, reliable tech, enhancing performance in telecoms, aerospace, and more with advanced materials and precise designs.