Turnkey PCB Assembly

Turnkey PCB assembly means the provider handles everything from component procurement to manufacturing and assembly. PCBX, serving 80+ countries, offers reliable, cost-saving, one-stop solutions with faster lead times and consistent quality.

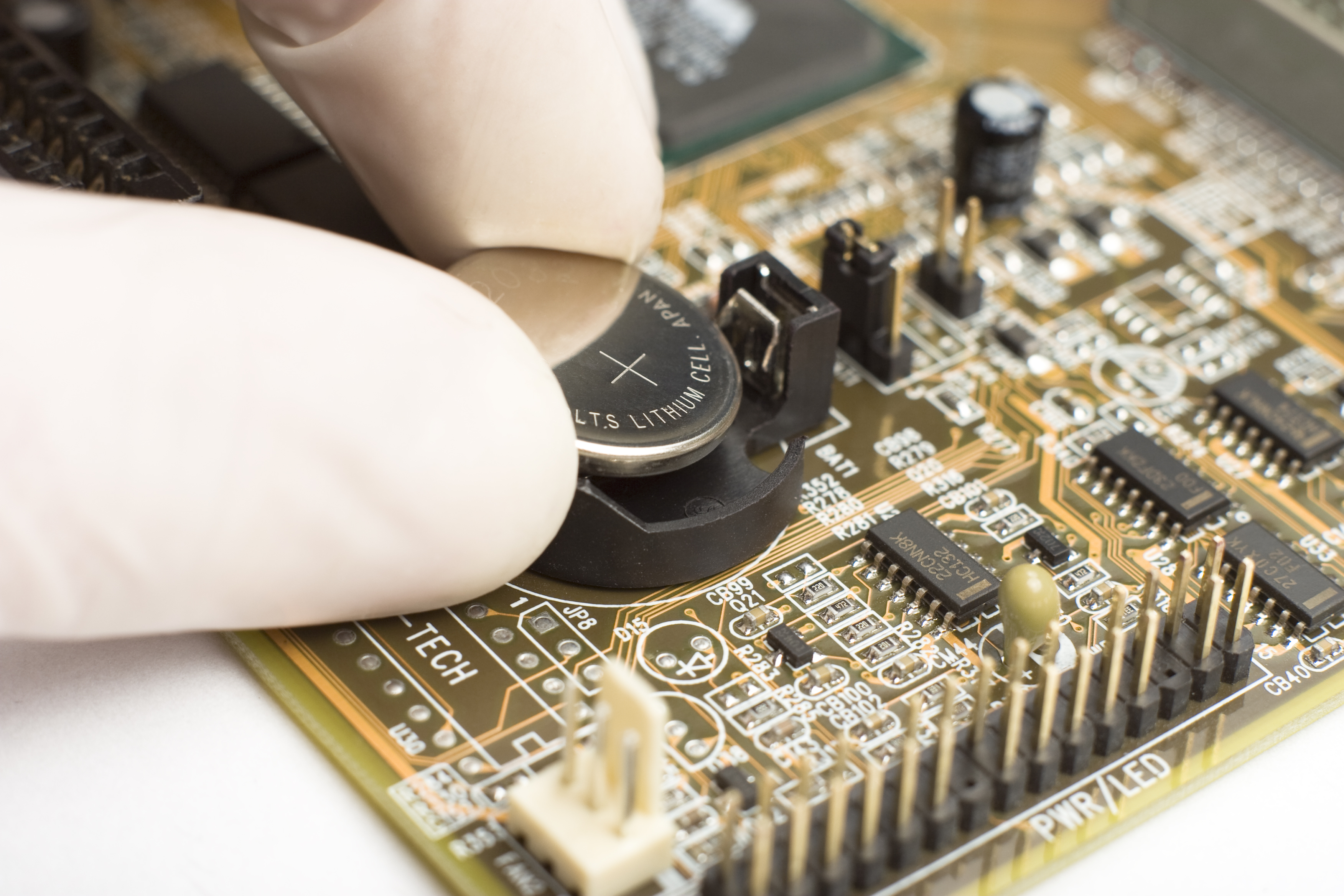

Turnkey refers to a product or service that is delivered to the customer ready for immediate use. In the context of PCB assembly, turnkey means that the provider manages all aspects of PCB solutions, including component procurement, PCB manufacturing, and exact placement of components on your custom PCBs. Essentially, a full turnkey PCB assembly allows the buyer to focus on PCB design while the supplier handles the rest, making it the best option for one-stop electronic assembly.

PCBX, a quality-centric PCB manufacturer, has over a decade of experience providing fast, reliable turnkey PCB assembly services to over 10,000 companies across 120+ countries. Our single-source approach not only saves you time and money but also ensures more reliable and consistent results compared to dealing with multiple suppliers.

Moreover, our skilled professional team can manage your entire project from start to finish, ensuring the electronic assembly process is as smooth and seamless as possible.

Benefits of Full Turnkey PCB Assembly Services

Shorter Lead Time

PCB assembly, a vital component of electronic production, is often divided into three phases: PCB fabrication, component procurement, and PCB assembly. Traditionally, each phase requires separate quotes and design confirmations with different entities—PCB manufacturers, component distributors, and PCB assemblers, which needs a considerable amount of time and effort spent liaising with various partners. If these partners are in different countries, additional challenges such as time zone differences and communication barriers may arise. In contrast, full-turnkey PCB assembly is a highly efficient approach. Once determined, a comprehensive assembly quote and essential issues preventing smooth manufacturing are addressed, reducing three separate communication instances to just one and significantly enhancing electronic assembly efficiency.

Cost Savings

Full-turnkey PCB assembly reduces total costs. Bundling the services typically proves cheaper than sourcing each separately. First off, since produced PCB boards and electrical components don't need to be shipped to the assembly workplace, you save money on freight. Additionally, purchasing components also gets easier and more affordable. Expert electronic assemblers frequently obtain dependable parts at reduced prices because of their established connections with distributors and manufacturers of parts.

Transparent Monitoring

Monitoring the manufacturing stage of your products is crucial for ensuring performance and timely market entry. However, this might be challenging in a fragmented process. Full-turnkey PCB assembly enables transparent tracking at each stage, allowing engineers to understand the progress and status of their tasks. This visibility ensures better performance and quality of the final products.

Who Can Benefit Most from Our Turnkey PCB Assembly Services?

Full turnkey PCB assembly enables PCB designers to maximize their time and concentrate more on design, making it an excellent fit for companies that frequently upgrade and refresh their products. These companies need to penetrate deeper markets by offering innovative electronic products that require a reliable and seamless electronic assembly process.

Turnkey printed circuit board assembly is also an ideal solution for small businesses or startups aiming to bring limited quantities of assembled PCBs to market without the need to invest in or maintain extensive inventories. This method offers a more cost-effective and efficient approach to assembling and testing PCB prototypes for new products. Additionally, quick-turn PCB assembly services are beneficial for any company that needs to receive their circuit boards in the shortest time possible.

Another big benefit of being a PCBX turnkey PCB assembly client is the ease of online quotation. We can estimate the labor cost for printed circuit board assembly based on your project specs and required quantities submitted into our PCB Tool. To improve our electrical assembly services, we keep your information in the cloud, allowing for quick and easy reordering of your circuit boards. Try it yourself by clicking the button below and requesting a quotation.

Tips to Speed Up Your Quotes

Ensuring a smooth and quick quoting process for your PCB assembly project is essential. Here are some tips to expedite your quote:

Review Our Preorder File Checklist: Ensure that your PCB files include all the necessary information we need.

Use Our BOM Template: Download our Bill of Materials (BOM) template and accurately fill in the required components.

Match Your Files with Our Capabilities: Before submitting your Request for Quote (RFQ), compare your files with our circuit spacing requirements, part polarity, and footprint or package specifications to ensure that your project fits within our capabilities.

Follow Our Guide: Use our step-by-step guide to submit your PCB Assembly Quote Request efficiently.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCBX offers fast, high-quality turn-key PCB prototype assembly services, including fabrication, component sourcing, and testing, all at competitive prices, to accelerate product development.

PCBs enable miniaturization, efficiency, and cost-effectiveness in electronics. Automated assembly further reduces costs, enhances accuracy, speeds production, and ensures quality.

Customers prefer one-stop PCBA service not only because of price transparency; it can save time and reduce labor costs with efficiency and professionalism in procurement and production.