PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

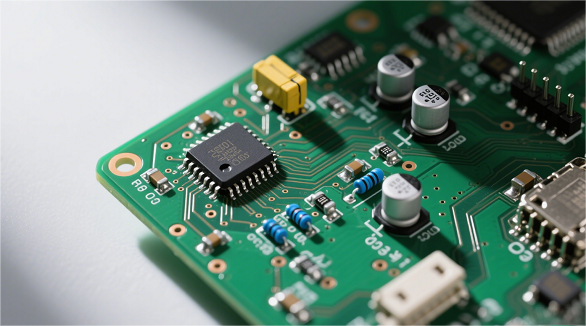

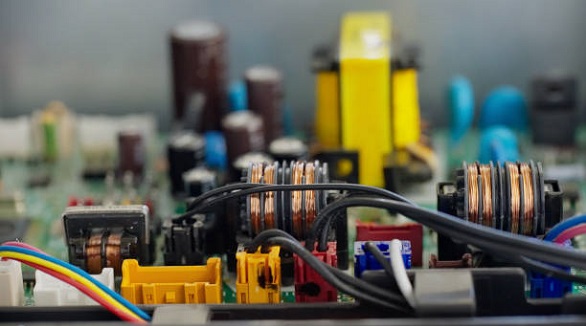

Electromechanical parts assembly integrates mechanical and electronic components for optimal device function, vital in modern PCBs and tech innovation.

Analog signals are crucial in electronics but susceptible to noise, which necessitates strategic PCB design to ensure high performance and signal integrity.

PCBs require rigorous reliability testing to ensure long-term durability, performance across industries, and standards compliance, minimizing failure risks.

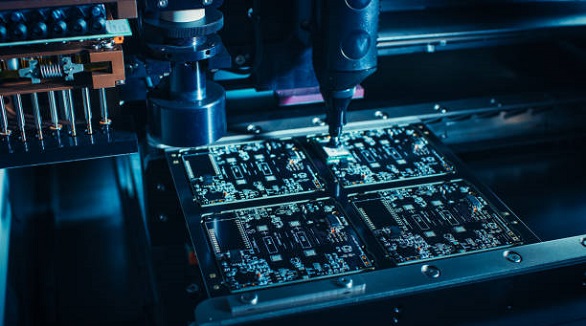

SMT contract manufacturing offers cost-efficient, high-quality PCB assembly, allowing businesses to focus on core strengths and adapt to market changes effectively.

Superior PCBA testing ensures quality, functionality, and reliability, using diverse methods to prevent flaws, maintain standards, and enhance electronics manufacturing.

Rectifier diodes convert AC to DC, ensuring devices receive correct power, essential in electronics, from power supplies to battery chargers, with high efficiency.

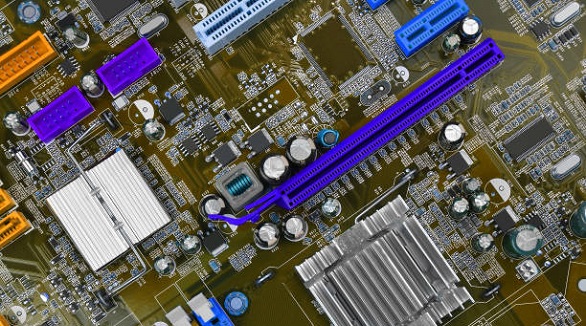

Package on Package (PoP) assembly stacks semiconductor devices vertically, enhancing space efficiency and performance in electronics with design flexibility.

BGA rework stations offer precision, automation, and cost-efficiency, solving challenges in high-density electronics by optimizing component alignment and heating.