Wire Harness Assembly

Wire harness assemblies enhance electrical system efficiency and reliability, crucial for PCBs in automotive, aerospace, and electronics industries through customization.

With the rapid development of technologies nowadays, the efficiency and reliability of electric systems are more crucial than ever. Wire harness assembly is the focus of these systems, and it is most essential in making products function at their optimal state. To professionals in design and assembly of PCBs, such as those in PCBX, a three-dimensional understanding of wire harness assemblies is critical to designing robust and effective electronic systems in various sectors of automotive, aerospace, and consumer electronics industries. This detailed handbook examines the complexity of wire harness assemblies, discussing their types, benefits, as well as manufacturing methods and design techniques used.

Understanding Wire Harness Assembly

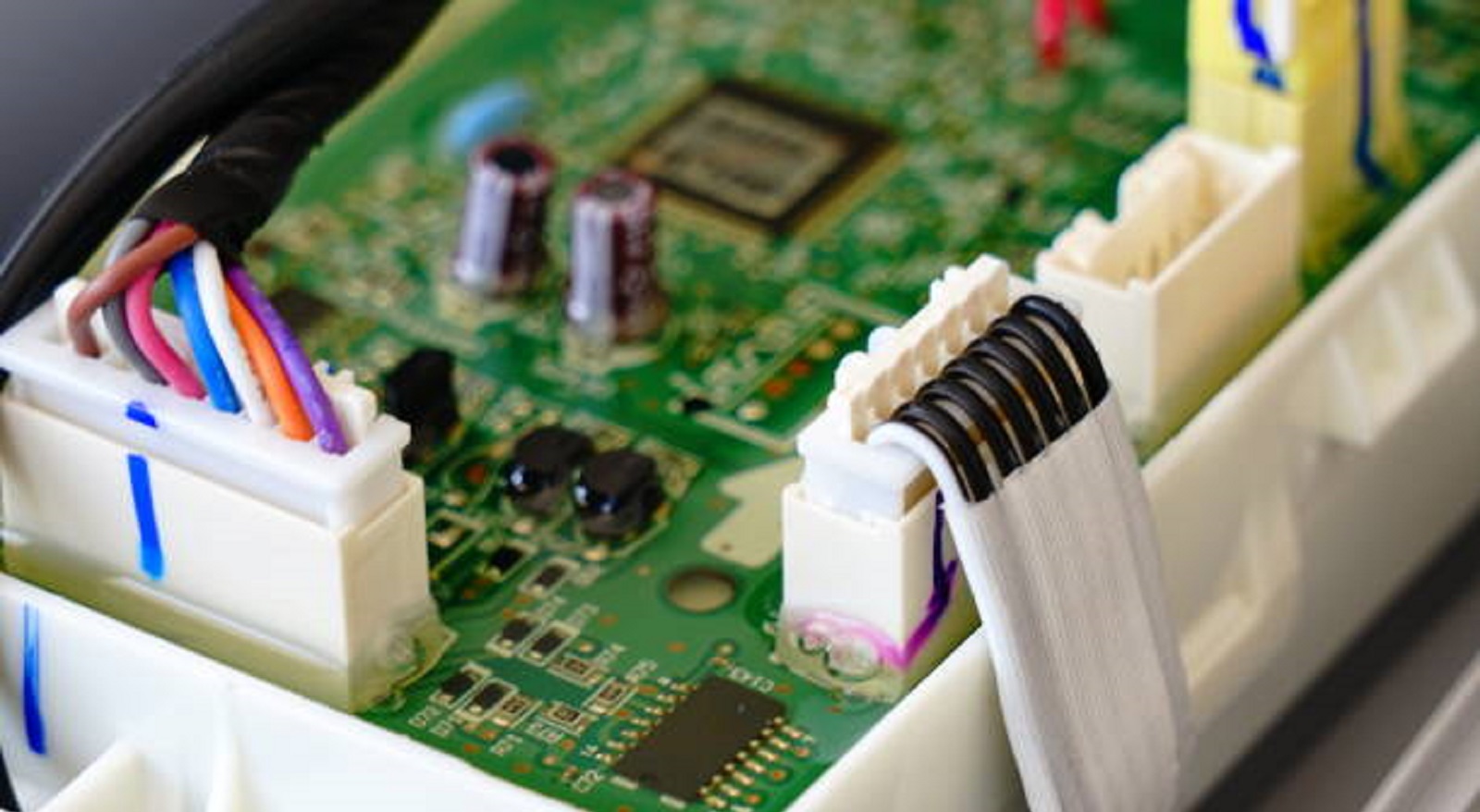

Assembly of a wire harness is the precise bundling and organization of separate electrical wires or cables into a single, unified unit. This highly organized setup, also known as a wire harness or wiring assembly, works in a similar way as a central nervous system among various devices, allowing for efficient transmission of electrical power or signals. By grouping a number of wires together into a single harness, manufacturers not only achieve better system organization but also ease the installation process and greatly increase the overall reliability of electrical systems.

Main Components of a Wire Harness

The design of a wire harness is made up of a number of main components, each contributing to its performance as a whole:

Wires and Cables: These form the fundamental pathways for the transmission of electrical power and signals throughout the assembly and are the foundation of the harness.

Connectors: These are employed to enable safe electrical connections between the wiring harness and other devices or systems.

Terminals: Connected to the terminations of the wires, terminals enable simple connectivity and disconnection to facilitate flexibility and convenient maintenance.

Sheaths and Sleeves: Critical protective cover, these components shield the cables from hostile environmental conditions such as heat, moisture, and abrasion.

Clips and Fasteners: These maintain the harness clean and secured in fixed positions to facilitate system integrity and order.

Labels and Identifiers: Critical for fault-finding and maintenance, these allow exact identification of connections.

Industry-Specific Custom Wiring Harnesses

Wire harness assemblies can be fully customized and tailored for specific industry applications, which is why they are critical in many industries:

Automotive Wire Harnesses

Automotive wire harnesses are tailored to accommodate the severe conditions of vehicle use. They connect critical systems such as engine management, lighting, sound, and safety features such as airbags and ABS. They are made tough, thermally resistant, and high-current-rated so that they can hold up to the hostile requirements of automotive environments.

Aerospace Wire Harnesses

Aerospace wire harnesses must fulfill stringent reliability and safety standards. They are used in safety-related systems like aircraft control systems, avionics, and power distribution systems. To satisfy performance criteria at adverse conditions and reduce aircraft weight, these harnesses have a tendency to utilize specialized light-weight materials.

Medical Device Wire Harnesses

Harnesses for medical devices require higher precision and reliability. They are employed in diagnostic equipment, patient monitoring, surgical instruments, and imaging machines. These harnesses are often required to be sterilizable and biocompatible based on the use in sensitive medical environments.

Industrial Wire Harnesses

Engineered to be durable in harsh industrial environments, these wire harnesses find their application in manufacturing equipment, robots, control panels, and sensor systems. They can endure exposure to chemicals, lubricants, and extreme as well as low temperatures, thus ensuring enduring durability under tough production conditions.

Consumer Electronics Wire Harnesses

Wire harnesses in consumer electronics are generally smaller and more compact and appear in computers, laptops, household appliances, and game consoles. These harnesses focus on space-efficient designs and high-quality signal transmission with maximal functionality in minimal form factors.

Benefits of Wire Harness Assembly

Having wire harness assemblies has several advantages that maximize the efficiency and reliability of electrical systems:

Improved Organization and Efficiency: Bundled wires in a harness reduce disorganization in electrical systems, facilitating easier installation and servicing. It also improves airflow and cooling in crowded spaces by making better-than-bundled alternatives possible.

Improved Reliability: Wire harnesses provide greater protection from environmental factors, reducing the likelihood of short circuits and electrical malfunctions by a significant margin. It also boasts improved stability under high-vibration situations, enabling it to function reliably for an extended period.

Cost-Effectiveness: While they might be more expensive to buy upfront, custom wire harnesses are cost-effective over time. They reduce installation time and labor costs, lower maintenance and repair costs, and increase product longevity by delivering uniform performance.

Space Optimization: By making fullest use of accessible space in thin designs, wire harnesses reduce the overall weight of electrical systems, and increase routing potential for intricate configurations.

Consistency and Quality Control: Using wire harnesses comes with standardized assembly processes, accomodating simpler quality control and testing. This standardization continues to provide consistent product and application performance.

Customization Options: Wire harnesses can be engineered with specific project requirements in mind, including custom wire gauges and lengths, specialist connectors and terminations, and application-specific insulation and shielding.

The wire harness assembly is the coming together of designers and functionality, being a crucial tool in transforming complex electrical designs into efficient, streamlined frameworks. To PCB design and manufacturing experts like PCBX, employing wire harness assemblies is significant in the development of high-tech electronic solutions. As technology continues to advance, the demand for these assemblies in constructing efficient and reliable systems will grow, underscoring their central contribution to the continued evolution of various industries. Through the support and implementation of effective wire harness solutions, industries are able to continue developing advances, innovate well, and maintain reliability in increasingly complex and interdependent systems.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

IPC Standards ensure quality, consistency, and global compatibility in PCB assembly, essential for innovation and reliability in electronics manufacturing.

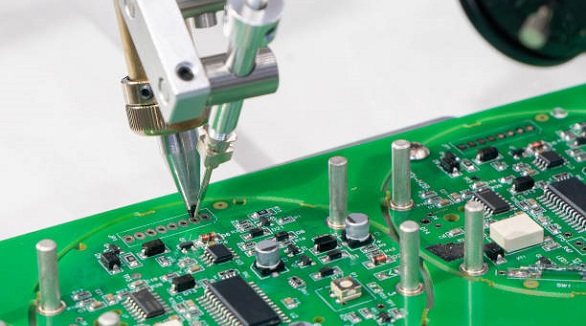

Ensure SMT quality through detailed design, supplier rigor, and process controls, enhanced by testing and continuous improvement for reliable, defect-free products.

Electronic module assembly is crucial for innovation, driven by demands for high-performance, reliable modules in fields like connectivity and electric transportation.