Benefits of Automated PCB Manufacturing and Assembly

Automated PCB manufacturing enhances precision, reduces costs, and accelerates production, enabling efficient, high-quality mass production and customization, vital for industry advancement.

In this fast-paced world of electronics, printed circuit boards, or PCBs, are the backbone for every electronics gadget, from smartphones to highly sophisticated industrial machines. The demand for more compactness, reliability, and efficiency in electronic devices continuously compels the PCB design and production processes to innovate. Traditional manual methods of assembling PCBs, which used to be the mainstay of their productions, are rapidly being replaced by automation nowadays. This shift isn't an upgrade but essentially a changeover that brings multiple benefits to the manufacturers. Let's explore how automated PCB manufacturing and assembly are revolutionizing the electronics industry.

Components of Automated PCB Production Line

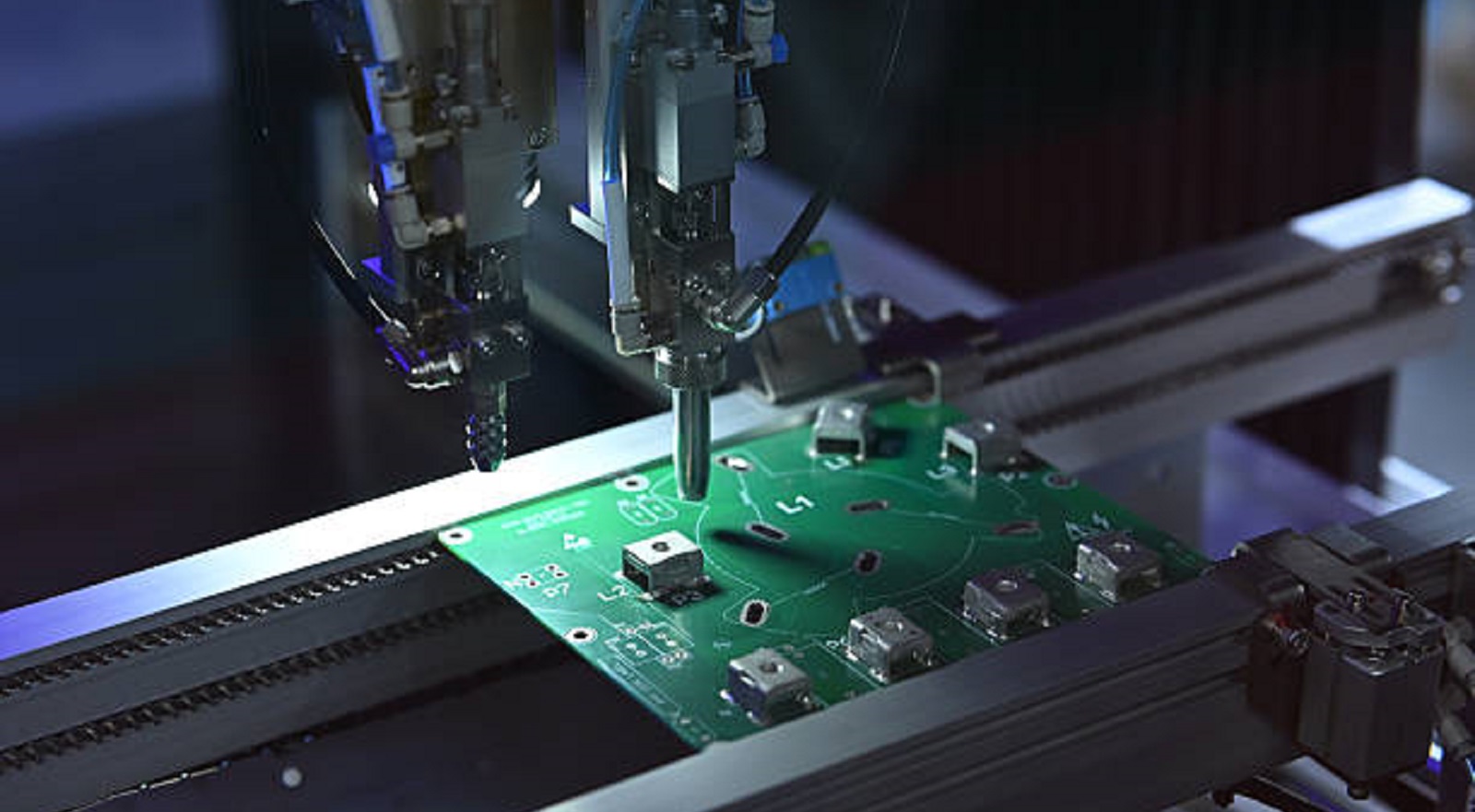

It all begins with understanding the benefits of automation through exploring critical components of an automated PCB production line; each component is vital in enhancing efficiency and precision.

Drill Through and Via Holes: With the process of manufacturing, first comes the need to drill through-holes and vias; these are necessary in connecting layers together inside a PCB. Using automation, high-precision drills can be used to achieve holes as small as 100 microns, a requirement also due to the miniaturization trend in current electronics. That guarantees precision not easy to get by hand for strong basic connectivity.

Photographic Mapping and Resistant Layering: Precise photographic mapping is conducted with the use of automated systems that apply photoresist layers using Gerber data. These photoresist layers are light-sensitive; thus, they become soluble or insoluble upon exposure, carrying the circuits' pattern to be applied to the board. This stage is important because copper traces with fill sections should be exactly as required.

Surface Treatments and Chemical Operations: Once the circuit patterns are laid down, the automated systems apply surface treatments to further strengthen copper and develop conductive paths. These methods of electroplating are not only accurate but also customizable to meet the various specifications that a client might have, thus ensuring quality for each different board.

HASL, Silk Screen, and Solder Mask Application: The automated solder mask is applied over all the PCB surfaces to protect the conductive paths against oxidation. Then, silk screen application for labeling components is done. Not only these layers ensure durability but are also convenient in the assembly of components and enhance the overall reliability of a board.

Systematic Routing and Profiling: The assembled PCBs are then trimmed and shaped to exacting design specifications using automatic routers. This ensures that each board is defect-free, prepared, and ready for other assembly processes without additional finishing, thereby greatly enhancing overall productivity.

Final Assembly, Test, and Dispatch: In this final stage, the PCBs are carefully tested to ensure they function as required. Automation reduces test errors to almost zero, ensuring every board meets our high-quality criteria. Once approved, they are cleaned, well-packed, and dispatched quickly for timely delivery in accordance with customer schedules.

Benefits of Automated PCB Manufacturing and Assembly

The transition to automated PCB manufacturing and assembly at PCBX presents many advantages over manual methods that transform the face of manufacturing:

Reduced Costs: The initial setup investment in automation technology is high, but the cost benefits are undeniable. Labor costs sink due to reduced personnel for supervision. Automation also minimizes waste and reworking of material, enabling manufacturers to keep production lines cost-effective. Precise automated processes offer early detection and correction of design flaws, hence decreasing expensive errors in latter stages.

Minimized Human Error: The sophistication of today's electronics requires a level of accuracy often beyond human capability. Automation of systems at PCBX minimizes any likelihood of errors in component placement or soldering. This accuracy is increasingly important for quality assurance as devices get smaller and more complex,

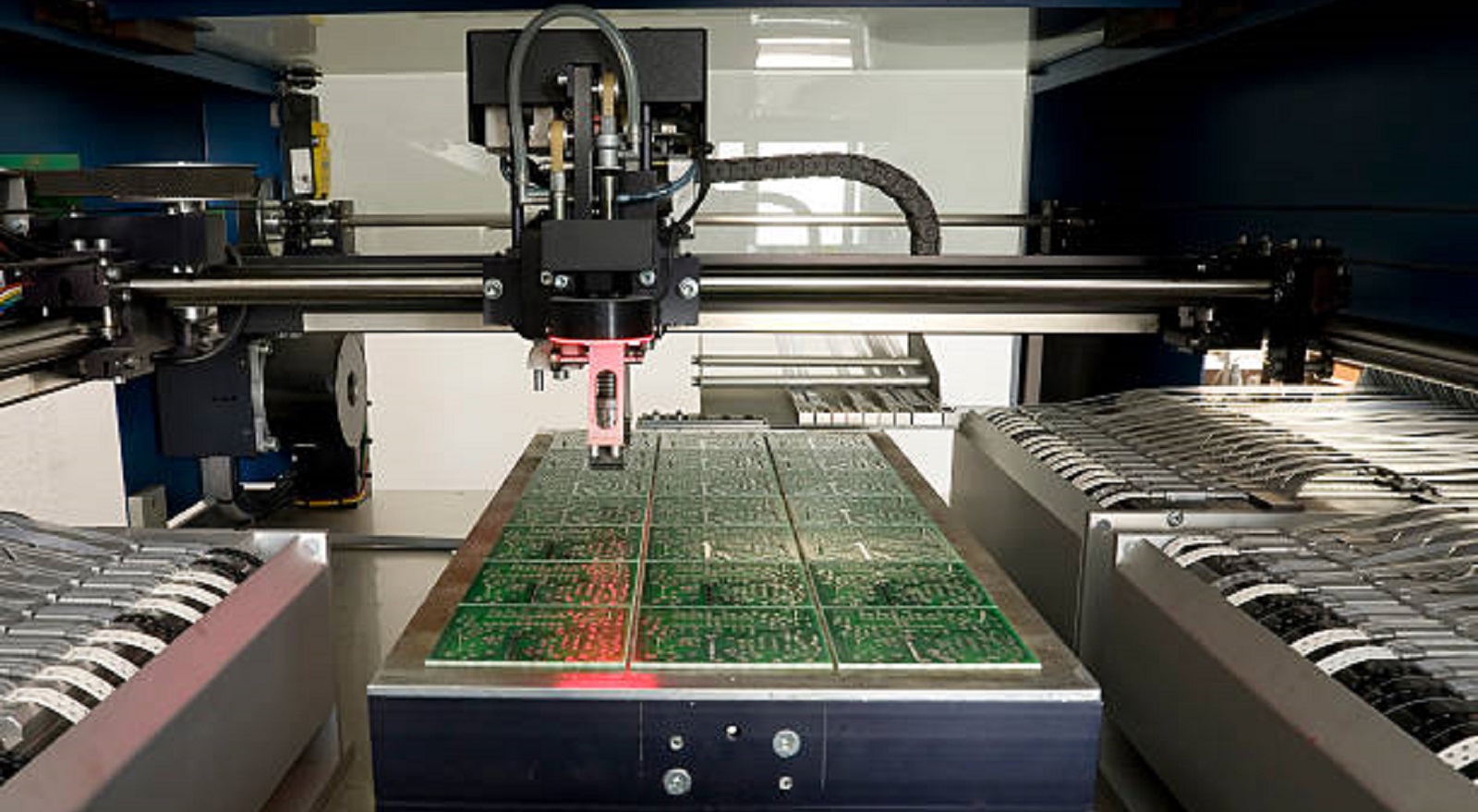

Accelerated Production: Automation allows for continuous, 24/7 production, greatly improving throughput. This enables the manufacturer to meet tight delivery schedules and to quickly ramp up the production volume to market demands, which again boils down to short lead times and faster time to market.

Consistency and Quality: Product uniformity and consistency are not very easy to achieve with manual labor, but under automated processes, every PCB will meet the stringent quality measures. This will evoke more trust from consumers and lead to fewer chances of returns due to defects, hence proving the quality guarantee of PCBX.

Ideal for Mass Production: Automation suits mass production by shortening production cycles and lowering costs, making it feasible to produce large quantities without compromising on quality. Manufacturers can confidently fulfill sizeable orders that would be impractical with manual methods, maintaining PCBX's reputation for reliability and performance.

Faster Time-to-Market: Streamlined production cycles reduce the gap between design and final delivery. In industries where being first to market can create huge competitive advantages, ensuring speedy and reliable production becomes critical. Automated systems afford such an edge to manufacturers to tap market opportunities quickly and respond to emerging customer demands with ease.

Higher Levels of Customization: Beyond efficiency and consistency, automation enhances manufacturing flexibility. It easily accommodates changes in PCB design specifications without causing significant downtime. PCBX's adaptive capabilities mean we can manage custom orders and swiftly adjust to new technological advancements or design changes, ensuring timely delivery and maintaining production schedules.

At PCBX, we believe that automated PCB manufacturing and assembly are not only about keeping up with the competition but an important strategy in driving efficiency, precision, and adaptability into production methodologies. With the continuous innovation taking place in the electronics industry and an increasing array of sophisticated devices required, automation will certainly play a vital role going forward. At PCBX, integrating the most advanced automated technologies means staying ahead in innovation and continuously delivering superior products within a fast-evolving market environment.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Electronic module assembly is crucial for innovation, driven by demands for high-performance, reliable modules in fields like connectivity and electric transportation.

Efficient PCB assembly needs component standardization, design clarity, optimized workflow, material management, defect detection, automation, teamwork, lean practices, and IoT integration to meet quality and demand.

The article explains the current situation of Printed Circuit Boards and future development based on efficient production helped by advanced software and manufacturing processes. Future technological developments are in store for 3D Printed Electronics, flexible PCBs, eco-friendly biodegradable PCBs, and board cameras. It elaborates on other powerful automation tools that are going to make the entire PCB design process efficient in the near future. All of them will further improve and develop with the technological advances in PCBs, keeping up with the ever-increasing industry and consumer demands.