Component Orientation and Polarity in PCB Design and Assembly

PCB failures due to minor orientation and polarity errors can impact reliability, but proper design practices and checks ensure manufacturability and performance.

In the complex domain of PCB (Printed Circuit Board) layout and assembly, some of the most expensive and aggravating failures occur due to what seem like inconsequential errors. Misplaced components, reversed LEDs, 90-degree rotated ICs, or backlit capacitors may seem like innocuous issues, but the effects can be drastic. Most of these issues tend to occur due to incorrect component placement or incorrect component orientation/polarity. It is vital to be aware of these critical factors to ensure the electrical correctness, reliability, and manufacturability of PCBs.

Understand Component Orientation and Polarity

Orientation of components is the direction in which a component is mounted on a PCB. Orientation of components is essential for proper mounting of components to PCBs, proper mounting by the pick and place machines, mounting of components, and positioning of the components. Even non-polar components, such as a resistor, require proper mounting to enhance the clarity of the automatic optical inspection and improve human readability to minimize errors.

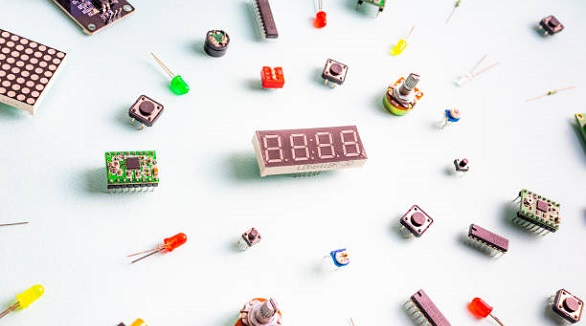

By contrast, polarity is the rule that specifies the electrical orientation of some components necessary for correct current flow. A polarized component will not function or will fail if installed wrongly. Examples of such components are electrolytic capacitors, diodes, LEDs, and ICs that can develop damaging voltages if installed the wrong way around.

Importance of Orientation and Polarity

The importance of orientation and polarity should not be underestimated. This will directly affect the electrical performance as well as the manufacturing accuracy of the PCB board. Wrong orientation will cause problems in the path of current flow, resulting in manufacturing defects in the board. This may include problems associated with capacitance, transistors, diode openings, as well as thermal expansion in the board.

Furthermore, with the increasing size miniaturization of electronics, issues with orientation and polarity are not longer "just assembly issues" but also very important design-oriented aspects. Understanding how to properly orient components, mark the orientation, and check orientation is a very important task for designers with any level of professional experience.

Identifying Orientation and Polarity

Learning the orientation and polarity of the components requires the recognition of specific indicators on both the component and the motherboard. Diodes and LEDs have inherent direction that can be determined by the use of cathode markings, markings on the component, and indicators on the light-emitting part. Polarized capacitors have markings that involve a + and - sign, where the longer part represents the + symbol. IC chips have specific Pin 1 references.

It is important to properly identify such indicators in order to avoid expensive Assembly errors and rework. Consider the case of IC orientation; this is important because assignments of pins for power and ground and I/O connections depend solely on Pin 1 location.

Diagnosing and Fixing Polarity Errors

Polarity errors are also common in well-designed circuits, especially when there are mixed manufacturer codes, reversed silkscreen footprints, and hasty manual assembly. One common polarity error is a reversed electrolytic capacitor on a power bus, which causes voltages to drop, resulting in overheating and higher current consumption. Troubleshooting polarity errors requires inspection, checking if component codes match PCB codes, and checking for proper functioning.

To correct the issue, one has to remove the soldered element, make sure that the designation on the pads is correct, and install a new component correctly. Prevention methods include the use of prominent silkscreen marks, the use of a standard library symbol set, and performing AOI verification tests.

Best Practices to Pave the Way to Success

Perfavore per evitare disorientamenti e instabilità nei polari, gli ingegneri sono tenuti ad adottare meglio la progettazione seguente

Make Use of CrystalClear PCB Silkscreen Markings: It is a good design practice to include '+' marks on capacitors, notches/triangles to indicate the position of the 1st pin of the IC, and bars to indicate diodes, according to the IPC-7351 specification.

Verify Component Orientation in Schematic and PCB Layout: Ensure that schematic component symbols represent actual component pin-outs. Take advantage of specific EDA software functions such as pin flip constraints and orientation locks.

Perform 3D Model Reviews: Employ the 3D viewing functionality to check the correct orientation of capacitors, connectors, switches, or IC chips against the board's mechanical limitations.

Communicate Clearly with Manufacturing Partners: Share accurate Bill of Materials, Pick-and-Place files, as well as Assembly drawings which clearly state the orientation of the different parts by including polarity comments as well as images.

Make AOI-Friendly Boards: Do not overlay silkscreen trademarks with components and provide sufficient contrast to ensure better AOI inspection results.

Manual Verification in Prototype Stages: Check the prototype boards in the correct orientation for the first units assembled and check the alignment in the continuity test.

Establish a Revision Control and Feedback Loop: Record orientation-related problems during the design revision process and implement changes to the library of components.

At PCBX, we have created a Design for Manufacturability or DFM process that helps us overcome orientation and polarity-related issues in assembled products. The Gerber file, BOM, and CPL are matched for errors and, with real-time AOI checks, potential mistakes are pinpointed on time. Designing with this approach, which is both manual and automated, guarantees that engineers at PCBX are able to provide optimal design solutions that are market-ready.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Castellated pads in PCB design facilitate easy board-to-board connections, enhancing miniaturization, assembly, solder quality, and flexibility for compact modules.

Capacitors are crucial in PCB design for filtering and timing. Correct polarity in electrolytic and tantalum types prevents malfunctions and ensures reliability.

Edge connector bevelling enhances PCB durability and reliable connections, vital for frequent usage and secure engagements, with limitations primarily in plating.