How to Create BOM for PCB Production?

A BOM is crucial for efficient PCB manufacturing, guiding the production process, reducing costs, and ensuring consistency and effective communication.

In the intricate world of electronics and printed circuit board (PCB) manufacturing, a well-constructed Bill of Materials (BOM) is an essential pillar of efficient production. As a comprehensive list of all materials, parts, and assemblies needed, a well-constructed BOM is imperative to ensuring proper, cost-effective, and efficient manufacturing processes. At PCBX, we understand the important role that a BOM is at the center of, and this manual outlines the most significant steps and factors that are involved in creating an accurate and professional BOM for PCB fabrication.

The Importance of a BOM in PCB Fabrication

A BOM is not a checklist; it is the hub of the production process in PCB manufacturing and other industries. By providing a specific inventory of everything and specifications, a BOM streamlines communication between customers and manufacturers, eliminating misunderstandings and delays. Without a robust BOM, projects will be reworked in the course of production, which stops timelines and costs.

Key Components of a BOM

A good BOM not only lists parts but also include important information to guide the manufacturing process:

Part Number: A unique number for each part that facilitates easy tracking and procurement.

Component Description and Specifications: Identify the part's function (e.g., in resistors, resistance and value).

Quantity: Indicate how many units of the part are required in the project.

Reference Designators: These designators trace the PCB layout, helping place each component with accuracy.

Manufacturer Details: Provide manufacturers' names and part numbers, along with alternate parts to serve in case of supply failure.

Package Type and Footprint: Describe the physical shape of the component and how it should be attached to the PCB to make board layout compatible with each component.

Procurement Type: Identify the point of production of components, whether internally or through suppliers, and how it impacts procurement strategies.

Preparation Steps for BOM Development

Before moving forward with the BOM development process, there are some preparation steps necessary to make it clear and effective:

Understanding of the Design Phase: Begin with understanding your project design in detail in order to identify required components and assemblies.

Management System: Implement a process for managing BOM revisions. Provide version control and edit rights to prevent unauthorized alterations.

User Identification: Determine who will be using the BOM in the production process, and include the details necessary to successfully complete their task.

Steps to Write a BOM

Select the Proper Platform: Use PCB design tools such as Eagle, KiCad, or Altium Designer that will automatically create a BOM from your design. Ensure it is in the correct format for your manufacturing partner's systems.

Structure the Document: Define user permissions, and create any hierarchical structures required. Maintaining data well-organized will make future updates and revisions easier.

Enter the Data Systematically: Complete the columns with important categories such as part number, item name, and required quantities. Ensure that each row corresponds to a different component in your project.

Update the BOM Periodically: As project details shift, update the BOM periodically so that it remains accurate and relevant. Periodic updates help to track changes and uphold project integrity.

Tips for Developing a Reliable BOM

Customization: Customize the BOM according to the unique requirements and complexities of your project. The format and level of detail must match your production demands.

Template Use: Use templates offered by your manufacturer or PCB assembler to ensure consistency and prevent format incompatibility.

Detail Focus: Provide all necessary and clear information to eliminate confusion and facilitate smooth manufacturing procedures.

Verification: Thoroughly check the BOM to identify and correct mistakes before production, as mistakes can jeopardize the success of the project.

Benefit of an organized BOM

A correctly prepared BOM entails the following major advantages in production, improving:

Cost Management: In that it ensures economies of scale through volume purchasing, a BOM enables good prices on parts and reduces logistic costs to enhance overall cost management.

Successful Data Management: It helps in coordination of planning and budgeting, keeping the production cycle in line.

Automated Design: A BOM maximizes Electronic Design Automation (EDA) by standardizing parts management, accelerating prototyping speed.

Failure Identification: A BOM aids in troubleshooting with ease by pinpointing potential points of failure, allowing manufacturers to make rectifications and replace failing parts instantly.

Manufacturing Consistency: Uniform use of a BOM across production runs ensures product consistency and optimizes manufacturing efficiency.

Types of BOM Structures

Single-Level BOM:

Best suited for simple products, itemizing each part only once and specifying their required quantities.

Multi-Level BOM:

Provides a hierarchical view, showing relationships between assemblies and subassemblies, and is best suited for complex designs.

In PCB production, the BOM is far from a dead document. It's an active document that guides the entire manufacturing process, so it becomes efficient as well as accurate. At PCBX, we emphasize the importance of an accurate, detailed BOM in producing quality PCBs. With proficiency in generating BOMs, manufacturers are able to significantly enhance their operations to deliver timely, low-cost delivery, and high-quality products.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

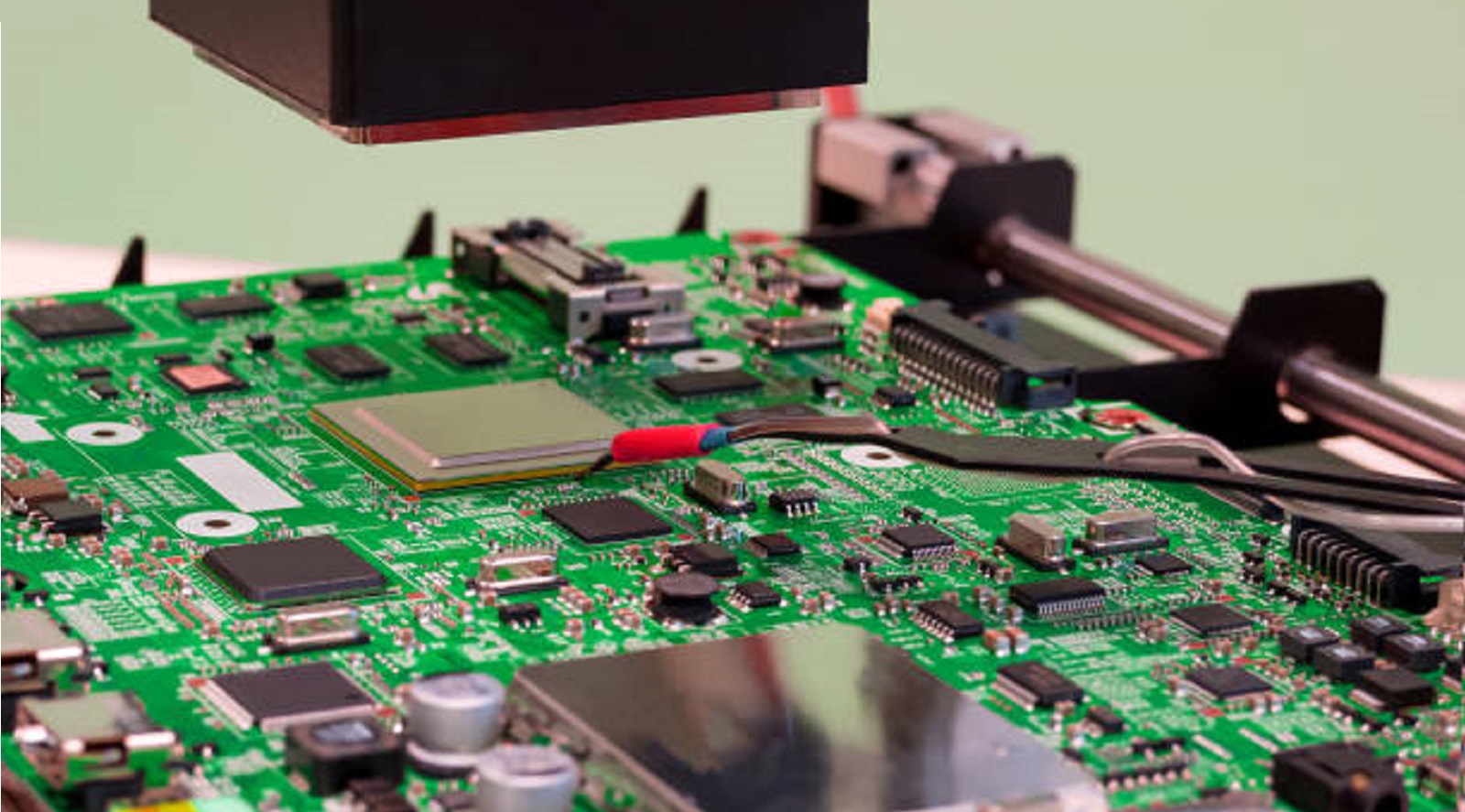

Efficient PCB assembly needs component standardization, design clarity, optimized workflow, material management, defect detection, automation, teamwork, lean practices, and IoT integration to meet quality and demand.

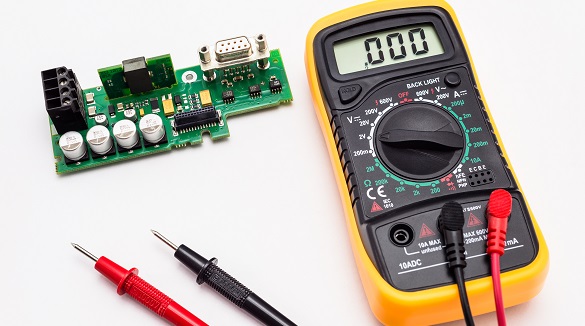

A multimeter is vital for electronics, measuring voltage, current, and resistance. This article covers its basic functions, settings, and guides you on PCB testing, ensuring accurate and safe troubleshooting.

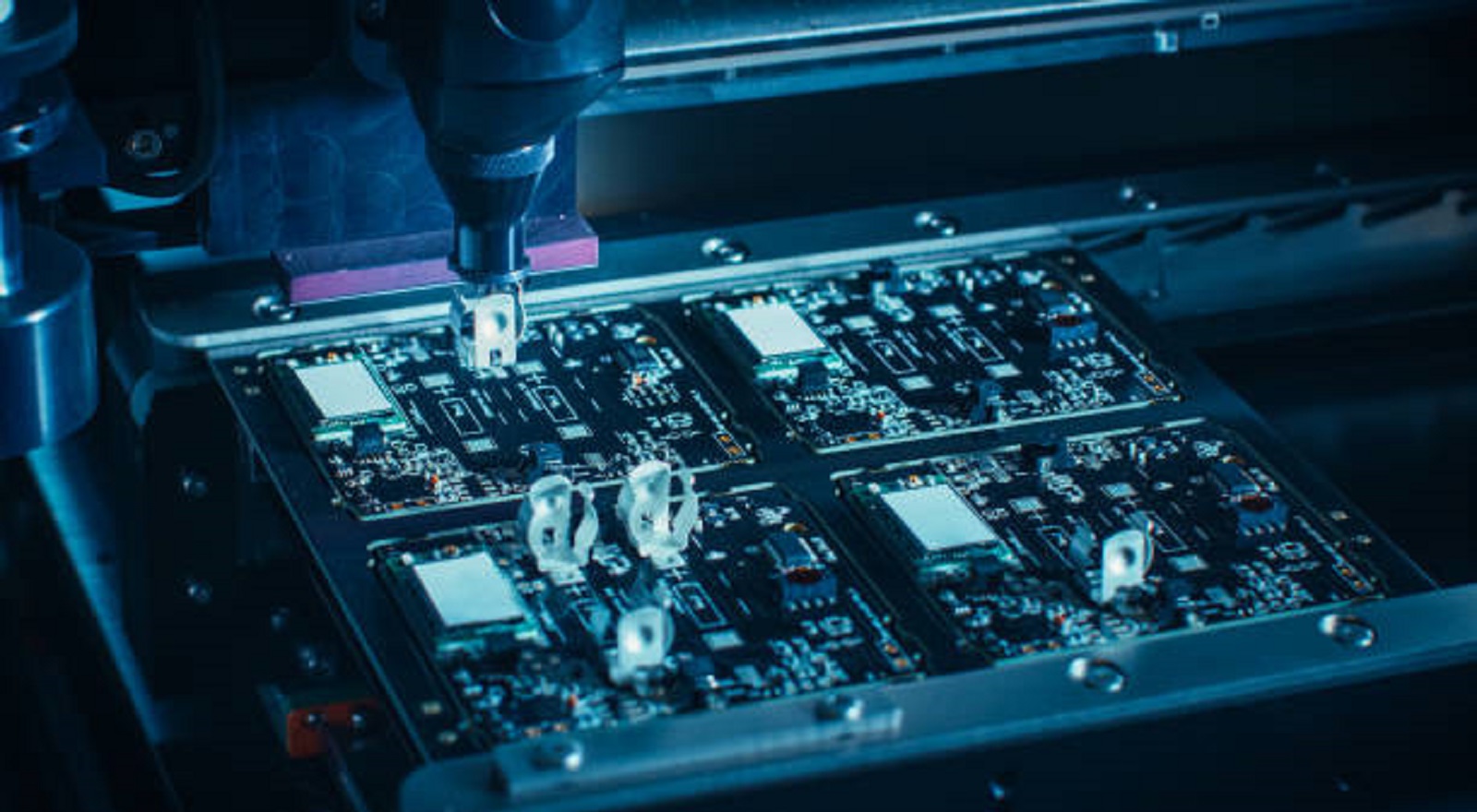

PCB prototyping is vital for testing and refining electronic circuits before mass production, ensuring performance and feasibility using methods like etching, milling, and 3D printing.