Stripboard vs. Perfboard vs. Breadboard

Prototyping in electronics uses stripboards for low-cost durability, perfboards for flexible custom layouts, and breadboards for quick, reusable testing setups.

In the changing world of electronics, prototyping is a very important stage before any commitment to a custom PCB. The three most widely used options for prototyping-stripboard, perfboard, and breadboard-have unique features for different stages and types of electronic development. Understanding these differences is crucial in making an informed decision for your project.

Stripboard (Veroboard)

A stripboard, also known as a Veroboard, features a side where parallel copper strips run on a fiberglass board. Indeed, this feature offers a brilliant way of interconnecting and thus serves as a preferred choice for making semi-permanent prototypes.

Key Benefits:

Low Cost: The very main advantage of stripboard is that it is low-priced. The stripboard is very cheap. This affordability makes the stripboard very useful for a hobbyist or a professional who wants to check a design for a circuit without investing in a custom PCB.

Ease of Soldering: The copper strips provide an easy way to solder components, as they ensure an easy path for electrical connections. Because of this, it is quite easier to handle, and more complicated circuits can be put together in an efficient manner. Components will be mechanically attached to the board.

Transferability to PCB: Once it has been verified that the circuit design performs as expected on the stripboard, it can easily be converted into a PCB design. In turn, designing in a stripboard helps create a custom PCB. Hence, it becomes an easy transition from prototyping to production.

To make prototypes of complex circuits with minimal expenses involved, stripboards can be a very good choice. They can also be used for production if tests are successful since modifications and improvements are allowed.

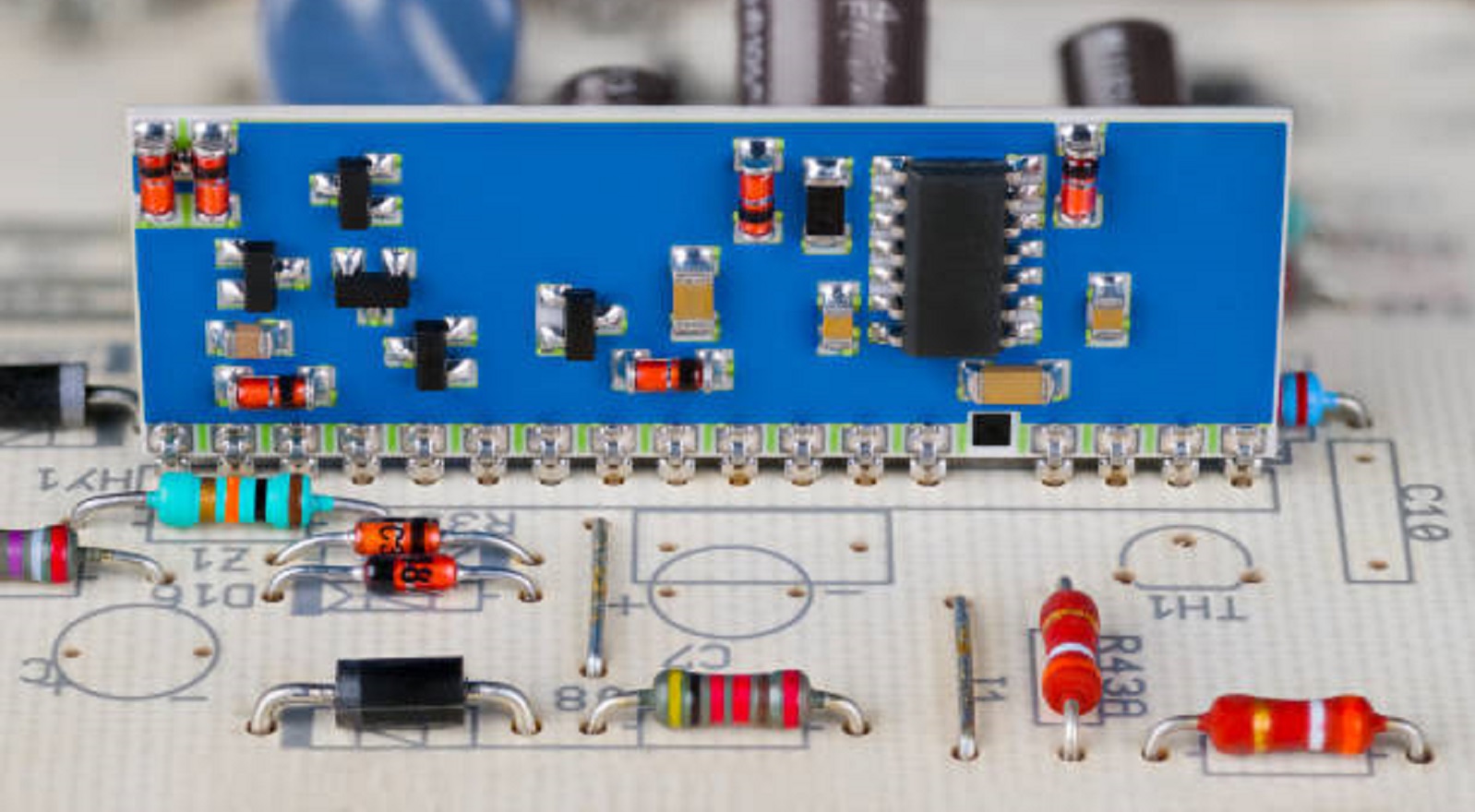

Perfboard

Perfboard is similar but has a grid of isolated holes, each with an individual copper pad. Unlike stripboard, there are no pre-defined tracks, giving complete freedom of layout design but at greater manual labour in wiring.

Advantages:

Specialized Layouts: The perfboard was designed to allow much variability in component placement. This amount of personalization is tailor-made for non-linear, unusual, or unique circuit configurations that offer creators much freedom to experiment.

Small Scale Production: Small production runs, mostly for simple circuit designs, are what perfboards are well-suited for. Once a reliable circuit is prototyped, it can then be duplicated with fairly easy assembly, making perfboards practical for projects that bridge prototyping and production.

Stable Connections: Providing a means to securely solder through-hole components and wires to individual copper pads, perfboards make for reliable connections that are critical in sustaining circuit integrity.

Perfboard is the tool of choice for low-volume assembly and experimental circuits where flexibility in component placement outweighs the additional effort for manual routing.

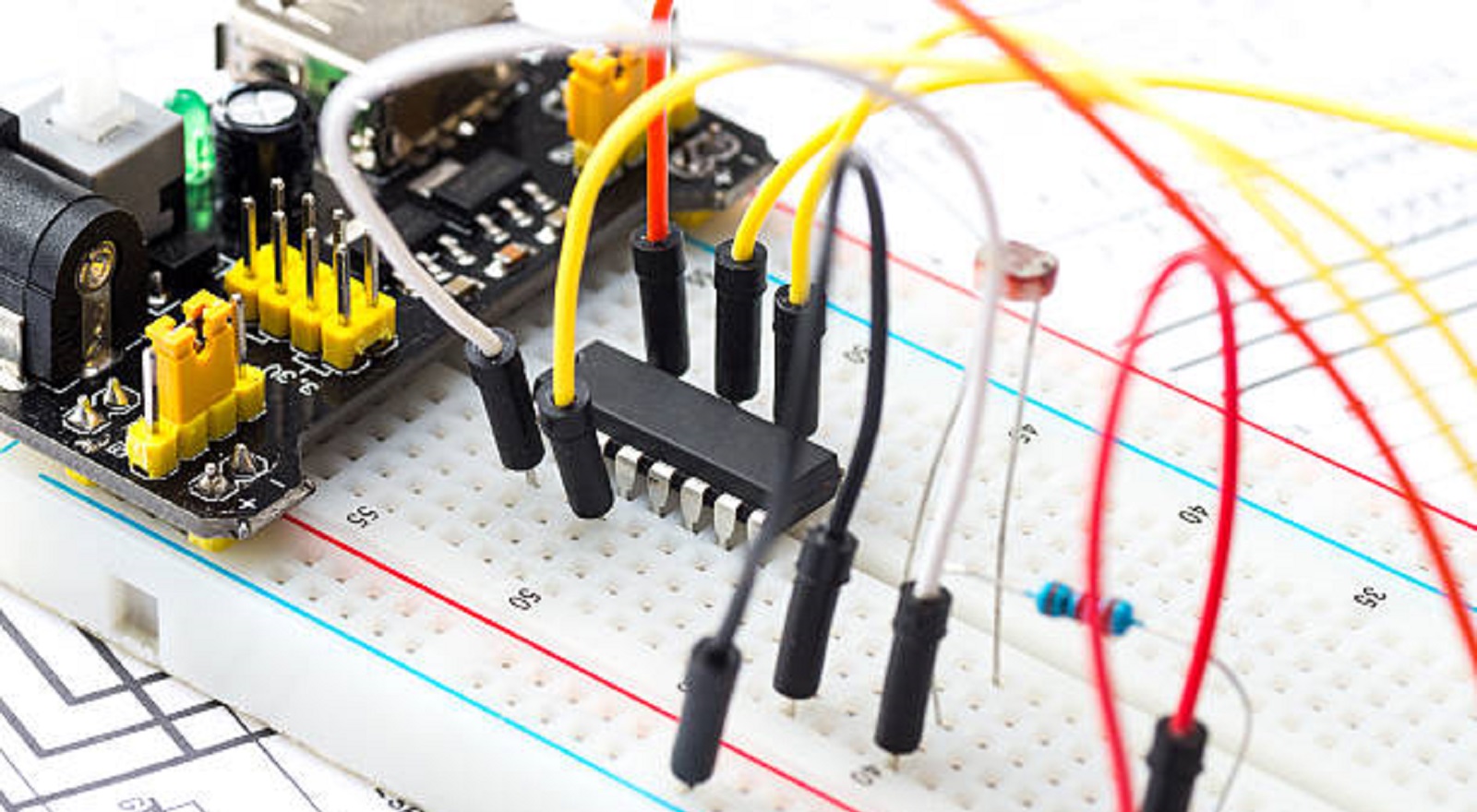

Breadboard

Breadboards are very useful for prototyping and, of course, in electronics design. A breadboard has a solderless construction consisting of a plastic board punctured all over and spring clips at the bottom of each hole to support the components.

Key Features:

No Soldering Required: One of the main advantages that breadboards offer to their users is the solderless feature, which facilitates easy insertion and removal. This capability increases the speed at which prototyping can take place, enables rapid iterations, and allows testing without committing to permanent soldering.

Ideal for Experimentation: The breadboards come in handy where some form of experimentation is necessary, where different arrangements or testing of the circuit layouts has to be done quickly. This allows designers to test configurations and component combinations quite efficiently.

Flexibility and Reusability: Breadboards can be continuously reused, and for this reason, they are extremely valuable in an educational context or during the first development phase of any design because designs usually change quite often. Their fast reconfigurability allows dynamic prototyping environments.

While breadboards perform quite well for initial circuit tests and educational use, they are not so good in terms of stability and performance, especially in more complicated or high-frequency design circuits. Temporary contact and loose contacts may also be some of the common performance variable points.

Additional Considerations

There are other factors to consider when selecting the appropriate prototyping board:

Ease of Use: Breadboards offer the fastest temporary circuit setup because they are plug-and-play. Stripboards allow for fast assembly in linear designs, since it is permanent with soldering. While perfboards offer complete freedom in design, their assembly is more time-consuming and attention-getting.

Connectivity and Stability: While breadboards are great for temporary usage and testing, they are not as reliable as soldered connections. Stripboards have soldered paths and hence are more stable, while perfboards provide the most robust connections for complicated designs.

Reconfigurability: The most straightforward reconfigurability is afforded with breadboards, making them ideal for the early exploratory phases. Stripboards will be semi-permanent but allow for some degree of modification in layout. Rework on perfboards, while possible, requires a more labor-intensive approach.

Appearance: While stripboards and perfboards are made up of grids of holes, breadboards often have marked slots and symbols to help along the process of prototyping.

The selection of the right type of prototyping board becomes a crucial step in the development life cycle that can easily make or mar any electronics development project in terms of efficiency and success. Breadboards apply where trials are needed at low cost, where changes have to be effected easily, or where education is involved. Stripboards are more suited to semi-permanent designs requiring durability at a low cost, while perfboards offer the flexibility needed for custom layouts and small-scale production. Understanding the strengths and weaknesses of each helps in the smooth transition from prototype to the final PCB design and will again help one's project for reliability and performance. To get tailored support or a detailed quotation on PCB manufacturing and assembly, contact us at PCBX today for it to apply knowledge and meet specific needs of your project.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Aluminum PCBs offer cost-effective thermal management for moderate applications, while copper PCBs excel in high-performance electrical and thermal tasks.

Pads and vias are crucial for PCB design: pads serve as soldering points for components, while vias connect different layers. Understanding and correctly implementing them ensures reliable, efficient, high-performance PCBs.

Choose between single-layer or multi-layer PCBs based on your project's needs. Single-layer is simpler and cost-effective; multi-layer offers complex functionality and durability. Evaluate based on functionality, size, durability, budget, and turnaround time.