The Art of PCB Thickness

PCB thickness is essential for device performance, impacting signal integrity, thermal efficiency, and durability, thus requiring careful selection for optimal outcomes.

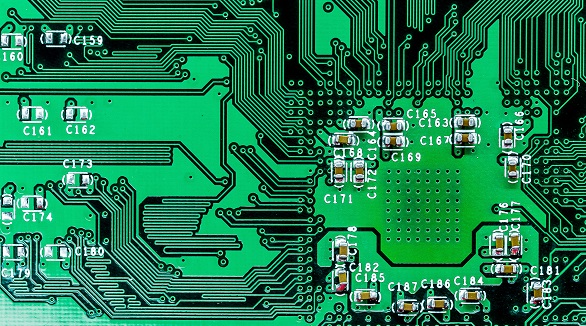

In the constantly changing world of electronics, the importance of Printed Circuit Boards (PCBs) cannot be overstated. Printed Circuit Boards are the backbone of all electronic devices, as they are the essential component that connects all the other components. Of all the parameters that are to be considered while designing PCBs, the thickness of the PCB is perhaps the most important. It is essential to comprehend the importance of PCB thickness, as it plays an important role in the design of PCBs.

Understanding PCB Thickness

PCB thickness is essentially the measurement between the top and the bottom surface of the PCB. It is usually expressed in mm or inches. It may seem like an easy parameter to comprehend, but PCB thickness plays an important role in the design of PCBs. The standard PCB thickness is between 0.6mm (0.024 inches) and 1.6mm (0.063 inches), which is perhaps the most appropriate range to meet the demands of most consumer electronics. However, with the increasing complexity of electronic devices, there is an increasing demand for PCBs that are both thinner and thicker.

Characteristics and Applications by Thickness

Ultra-Thin PCBs (<0.6 mm)

These are ultra-thin PCBs that are extremely lightweight and flexible. They are meant for situations where every millimeter of space matters. These boards cannot handle heavy components, so they are not meant for bulky components. These are best for wearables, flexible displays, smartphones, laptops, and drones. The main advantage of these boards is that they are flexible and compact.

Mid-Range PCBs (0.6–1.6 mm)

The middle ground between rigidity and flexibility. They’re good for components of moderate weight, offer good electrical insulation, and work well within a typical production process. They’re used in consumer electronics like tablets and computers, home appliances, and other general electronics. The 1.6 mm variant is particularly popular because it’s a safe middle ground without increasing production costs unduly.

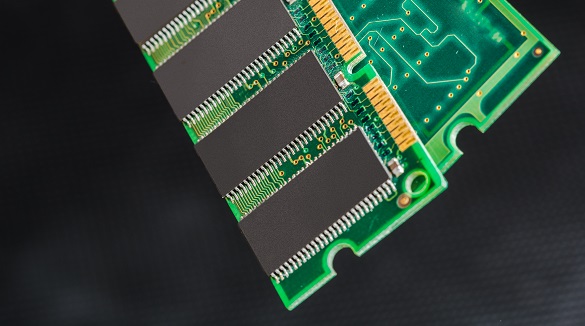

Thick PCBs (>1.6 mm)

With increased thickness comes better support for components and better heat dissipation due to thermal mass. They’re used in industrial control systems, automotive and aerospace electronics, and power electronics, where components are typically heavy and thermal/mechanical stresses are high.

Key Design and Manufacturing Considerations

Design Considerations:

Component Density and Weight: If more large components are being included, pushing the density of the PCB, the PCB will need more thickness to counter warping. This is especially relevant if the device is designed with multiple heat sinks.

Signal Integrity: If the device is designed for high-speed digital or RF work, the PCB’s thickness impacts the dielectric properties. The PCB’s thickness will need to be carefully selected to ensure signal quality is preserved.

Space Considerations: The size of the device will dictate the possible thickness of the PCB. More compact devices require thinner PCBs, while more spacious devices can be designed with thicker PCBs.

Manufacturing Considerations:

Etching and Plating: The thicker the PCB, the more etching and plating are required, which can increase the cost of the PCB.

Drilling and Routing: Drilling and routing will also have an impact on the thickness of the PCB, which might result in higher costs.

Material Costs: The thickness of the PCB will have an impact on the cost of the raw materials used, which will result in higher costs.

Special Considerations for Flexible PCBs

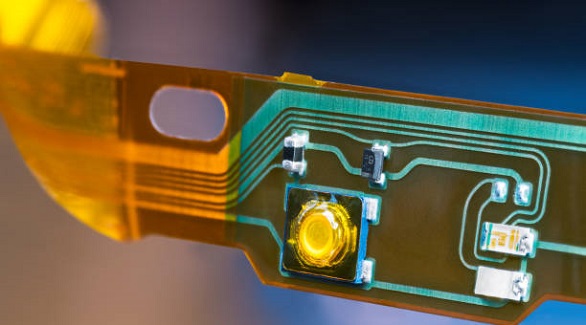

Flexible PCBs have some special considerations that need to be taken into account while designing the board. The role that flexible PCBs play in dynamic systems, which are subject to bending and twisting, requires that the thickness of the board be chosen properly.

Bendability and Durability: The thickness of the board will have an impact on the bendability and durability of the board.

Material Selection: Material selection plays an important role when designing a board, and the best option is the use of polyimide, which can withstand temperature and stress variations.

Selecting the Appropriate PCB Thickness

Selecting the appropriate PCB thickness is not random. It depends on the functionality of the board, the components it holds, and the capabilities of the PCB fabrication facility.

Usage: If it is a portable device, you can go for a thinner board. For industrial equipment, you may need a thicker board for durability and improved heat dissipation.

Components: If you are using heavy or hot components, you may need a thicker board to hold everything together.

Signals and Mechanics: The requirements for impedance, the required ruggedness of the board, and the size of the finished product also determine the appropriate board thickness.

Cost and Manufacturing: Compare the cost of materials and manufacturing with the requirements for performance. Verify with the manufacturers that they can produce the board with the technology they have.

PCB thickness is more than just a value on a copper and fiberglass layer—it’s a fundamental design consideration that impacts signal integrity, thermal efficiency, and durability. By understanding these dynamics and working with reputable PCB manufacturers, engineers can optimize boards for optimal performance and value. Selecting the optimal thickness for a given application is key to ensuring the success and longevity of your devices in the competitive electronics industry. Whether you are needing it safe with traditional FR-4 or exploring new and exotic materials, the optimal thickness is at the forefront of creating innovative solutions. As a premier supplier, PCBX has the knowledge and customization expertise to help you live up to these rigorous requirements.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Flex PCB thickness affects performance, offering flexibility, compact design, and durability but demands careful material selection and precise engineering.

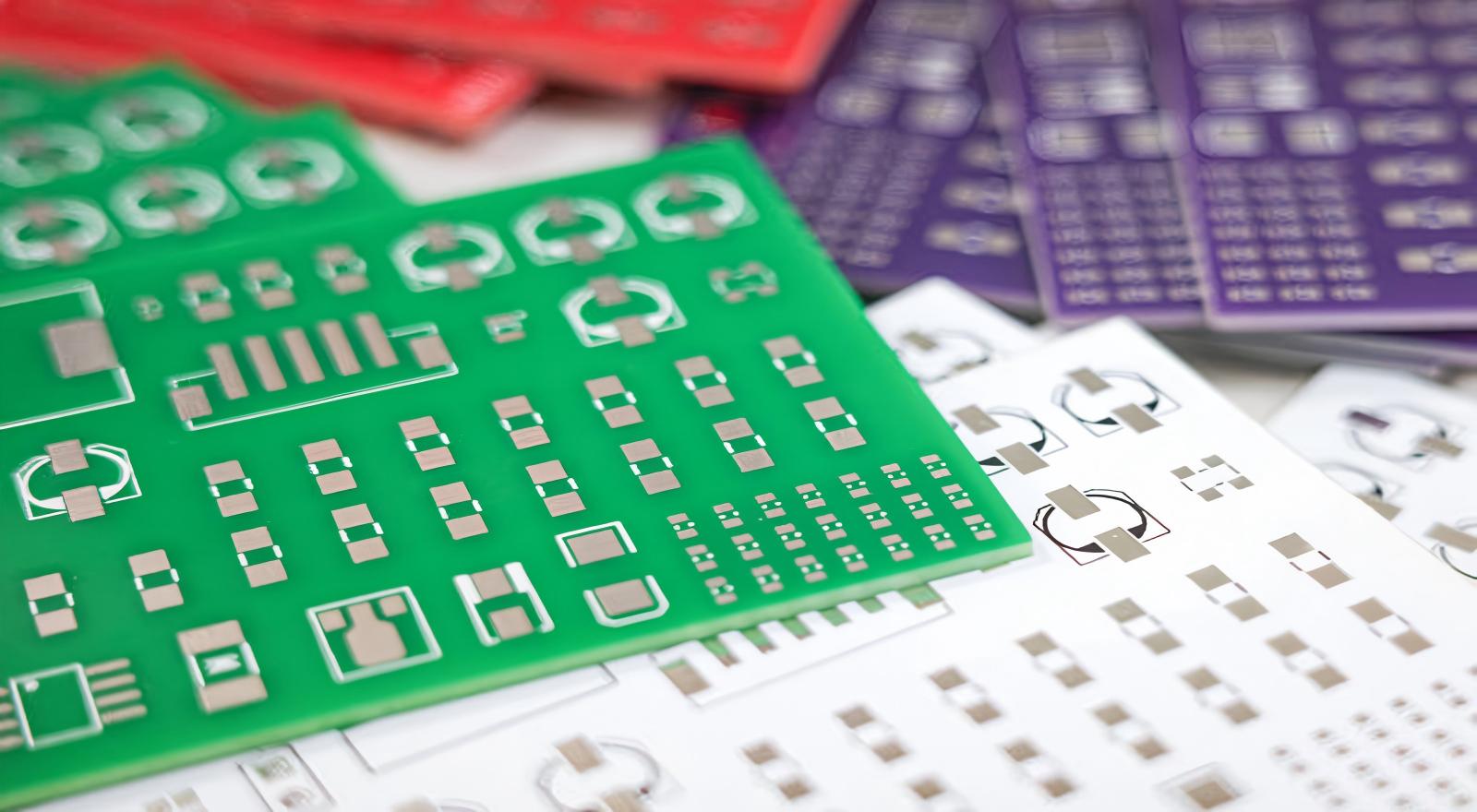

Solder masks protect PCBs from damage and solder bridging. Available in various types and colors, they ensure reliability. Eco-friendly options and precise thickness measurements are crucial for quality.

PCB thickness is crucial in electronics, influencing performance, durability, and cost. The standard thickness is 1.57mm, but other sizes exist for specific needs. Factors like copper thickness, material choice, layers, and environmental conditions determine suitability. Custom thicknesses cater to high-power, space-limited, and high-frequency applications but may increase cost and production time. PCBX offers various thickness options, emphasizing quality and customer service in PCB manufacturing.