Thermocouple Circuits and Integration

Thermocouples are essential transducers that convert heat into electrical voltage, requiring no external power, and are integral in accurate temperature measurement within modern PCB design.

Thermocouples are essential for temperature measurement due to the fact that they are cheap, robust, and find a broad range of usage. Thermocouples are active transducers, which convert changes in heat into electrical voltage through not requiring any external power. This article includes the basic specifications of thermocouple circuits, including their operating principles, construction, measurement method, advantages, limitations, and usage, particularly in current PCB (printed circuit board) design. By knowing these areas, the importance of thermocouples in providing stable and accurate temperature readings across multiple industries is understood.

Principle of Thermocouple Circuit

Thermocouple circuits operate predominantly on the Seebeck effect with some additions to the Peltier and Thomson effects:

Seebeck Effect: At the heart of thermocouples is the Seebeck effect, whereby a voltage is generated by a temperature difference between junctions of two dissimilar metals. The voltage is proportional to the temperature difference, and it serves as the foundation for temperature measurement.

Peltier Effect: As the reverse of the Seebeck effect, the Peltier effect is the effect caused by a temperature difference upon passing a voltage across conductors. This is the basis for understanding thermoelectric cooling and heating principles.

Thomson Effect: Though less energetic, the Thomson effect is voltage induction for a conductor with a temperature differential.

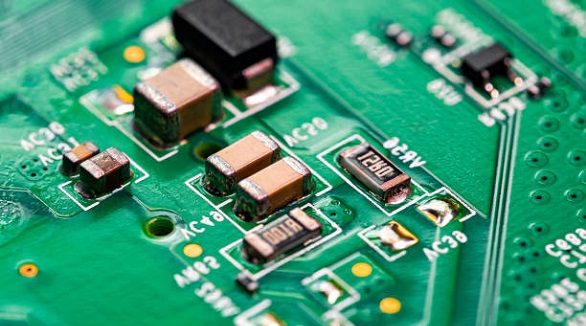

Thermocouple Circuit Construction

Two unlike metals are welded together at a junction and form the point where the temperature is measured. The arrangement of these junctions has a great impact on performance:

Ungrounded Junction: Independent of protective sheath, this is one that minimizes magnetic interference, which is ideal for use at high pressures.

Grounded Junction: The junction is welded to the sheath for enhanced longevity and noise resistance in corrosive environments.

Exposed Junction: In applications where very rapid feedback is required, this form is most suitable for quick response time, e.g., measurement of gas temperature.

Proper material should be chosen with common types like Type K and Type J used with certain temperature ranges for various applications.

Measurement of Thermocouple Circuit Output

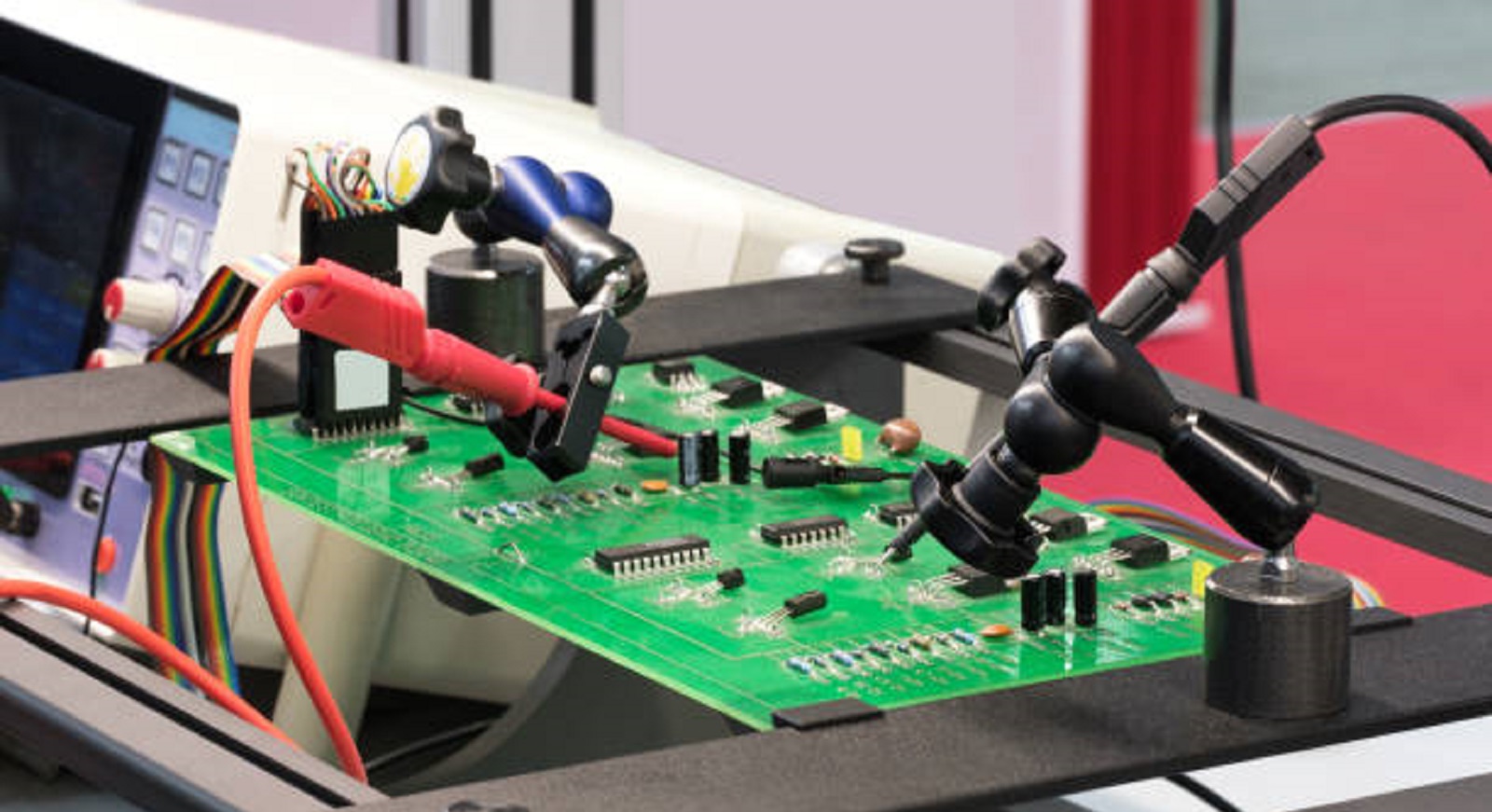

Volts from a thermocouple circuit may be measured by the following:

Multimeters: A simple piece of equipment that contacts the cold junction to measure voltage and display the reading in terms of equivalent temperature.

Potentiometers: These are precise measurements based upon the comparison of thermocouple EMF with recognized voltage standards and are suitable for delicate applications.

Amplifiers: Used to enhance the level of the thermocouple signal before sending it to a display or recording device to ensure that signal quality is sustained across far-off locations.

Advantages and Disadvantages of Thermocouple Circuits

Advantages:

Thermocouples provide numerous advantages:

Broad Temperature Range: Capable of being used in a wide range of temperatures, typically outside other sensor limits like RTDs.

Durability: Their solid construction is ideal for harsh industrial environments, like furnace temperature monitoring or steel production.

Cost-Effectiveness: Economical and easy to construct, thermocouples are extensively used in various applications including automotive and HVAC.

Disadvantages:

Although they have their benefits, there are some disadvantages of thermocouples:

Calibration and Compensation: Accurate measurement requires accurate calibration and cold junction temperature compensation. Inaccurate compensation will result in significant errors.

Signal Interference: Long lead wires can generate noise, which calls for shielding and grounding techniques to prevent loss in accuracy.

Radiation Sensitivity: Thermocouples are radiolytic, and radiation induces voltage, giving rise to false outputs and reducing their efficiency during high-radiation environments.

Failure Modes

Thermocouple circuits can fail due to open or short circuits:

Open Circuits: These inhibit the flow of current, typically generating off-scale or erroneous temperature readings.

Short Circuits: Cause current leakage and incorrect measurements, and thus proper circuit design and maintenance are very important.

Applications of Thermocouple Circuits

Thermocouples are extremely common and used across numerous industries:

Industrial Production: Essential for ensuring precise temperatures in steel and glass production processes.

HVAC Systems: Essential for sensing and controlling environmental temperatures, enhancing system efficiency and comfort levels.

Temperature Control Devices: Built into equipment like refrigerators and air conditioners for easy automatic temperature control.

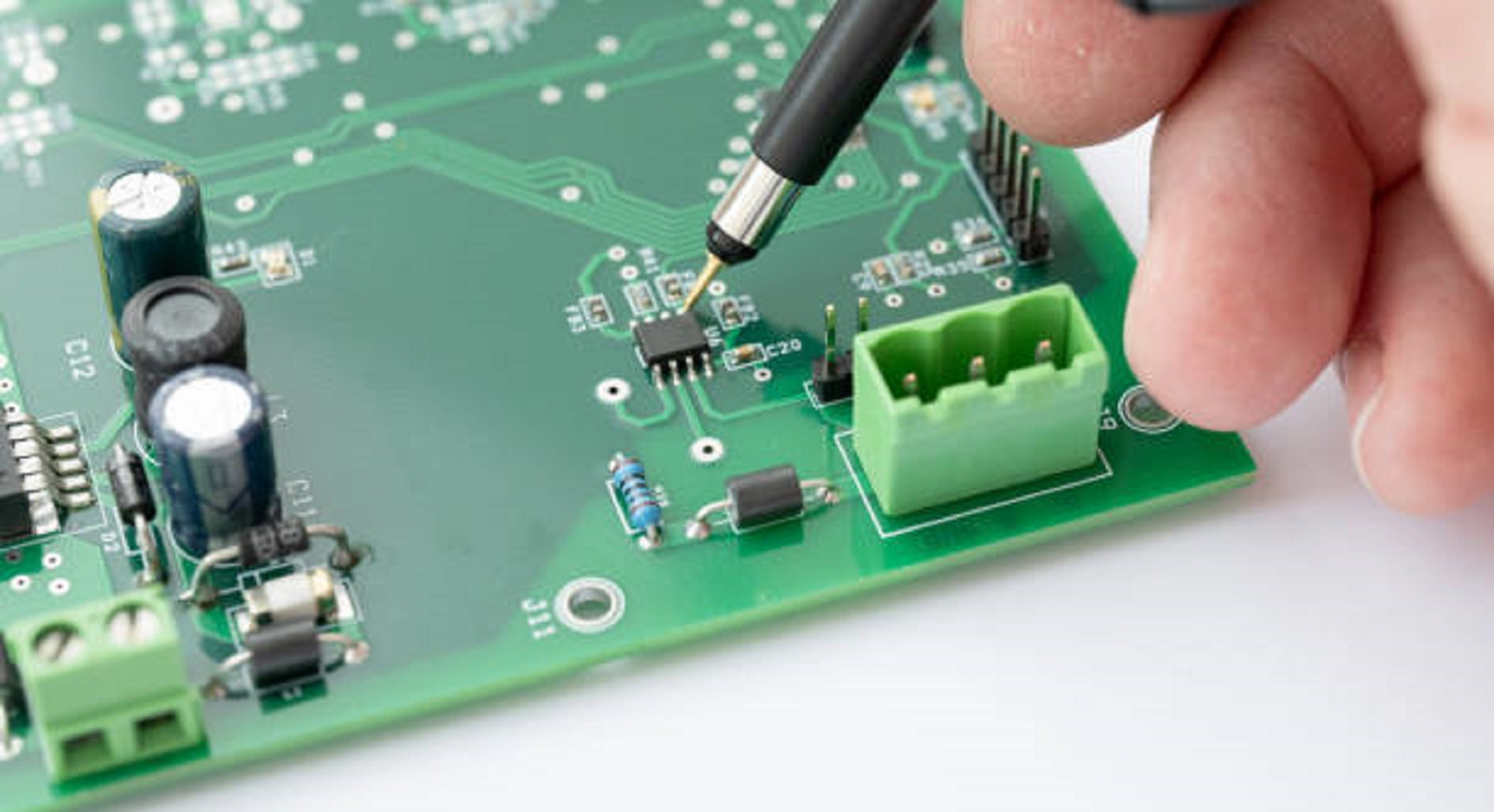

Integration with Modern PCBs

Thermocouple implementation in electronic circuits requires careful PCB design for the best signal integrity and to prevent interference. Advanced PCB solutions enhance the function and performance of thermocouple circuits by incorporating features like cold junction compensation and signal conditioning. Familiarization with these design elements is essential to creating systems that can deliver precise and stable temperature measurements to meet the demands of advanced applications.

Thermocouple circuits form the pillars of precise temperature measurement, valued for their extensive range, durability, and low cost. Their use in modern electronics, particularly through shrewd PCB design, proves their continued significance and versatility. By overcoming the ideas and challenges of thermocouple circuits, markets can leverage these components for accurate temperature measurement, vital to high-tech industrial application. As technology continues to advance, thermocouples will remain an integral part of the expanding world of temperature measurement and control.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Battery Protection PCBs ensure safety by preventing overcharge, over-discharge, and short circuits, crucial for efficiency in modern rechargeable devices.

High-speed PCBs (>1GHz) are crucial for advanced electronics like 5G and data processors. Key practices include ensuring signal integrity, controlling EMI, and maintaining power integrity for reliable performance.

Capacitors are crucial in circuits for storing energy. Testing methods include in-circuit and out-of-circuit using digital multimeters, ESR, and LCR meters. Proper testing ensures reliability and prevents malfunctions.