UL PCB Marking in Ensuring Printed Circuit Board Safety

UL PCB marking ensures safety, compliance, and reliability, enabling global market access and fostering consumer trust by conforming to strict industry standards.

With the greater application of technology in the world today, printed circuit boards (PCBs) make up the entire electronic device, from consumer products to complex machinery in industry. With this comes the necessity for safety and reliability. Even a single defect in a PCB can lead to product failure with significant hazards attached. UL PCB marking is a crucial element that guarantees safety, reliability, and compliance, ensuring PCBs conform to the highest industry standards.

Understanding UL Certification

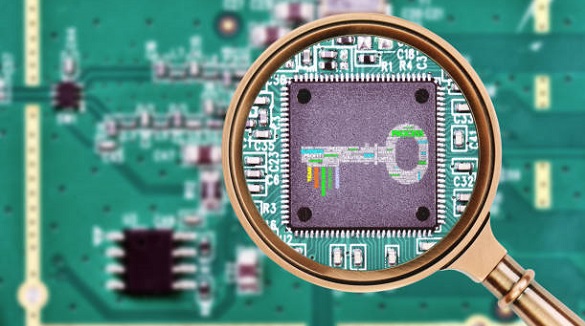

Underwriters Laboratories (UL) is an established global safety certification authority that enforces high standards across sectors, including electronics. The fact that a product bears the UL mark implies that it has successfully passed testing and safety standards with rigid focus on fire resistance and electrical efficiency. This kind of certification is of utmost importance in ensuring that PCBs are safe enough to be utilized extensively.

Improving Safety Standards

Fire and Electrical Safety: UL PCB marking ensures all boards adhere to stringent safety standards, reducing threats from fires and electrical failures. A UL-marked PCB provides customers and manufacturers assurance of its safety and usability.

Global Market Access and Compliance: By complying with UL standards, products can confidently enter and compete in markets all over the world. UL-certified products are internationally recognized as being to American and Canadian standards of safety, resulting in no replicated testing in various markets and reduced time to market.

Ensuring Reliability and Quality Assurance

Obtaining UL certification requires stringent testing and adherence to requirements like UL94 for flammability and UL796 for construction. These requirements are essential to assure PCB quality.

Flammability and Safety Standards: UL94 standards ensure PCB materials will not catch fire when exposed to heat, which protects against fire hazards. For example, a UL94 V-0 rating signifies the material will extinguish itself in 10 seconds, an important aspect to ensure safety in varied applications.

Durability and Longevity: UL's rigorous testing guarantees that material defects are detected early on, thus enhancing the reliability and lifespan of a PCB. This ensures not just performance efficiency but also prolonged product integrity, especially crucial for consumer and industrial applications.

Building Consumer Confidence and Competitive Edge

Consumer Confidence: The UL mark is more than a safety badge; it's proof of a manufacturer's dedication to quality. Consumers will seek out the UL mark on products as an indicator of reliability, putting manufacturers at the forefront of consumer confidence and competitive markets.

Promoting Innovation Within Safety Parameters: UL standards provide a ground on which manufacturers can innovate with updated designs in a safe way. This empowers companies to innovate without compromising on safety and reliability, offering innovative solutions without compromising on functionality and safety.

Effective Marketing with Safety Standards

Inclusion of UL marking in promotional activities enhances a manufacturer's reputation for safety and quality. UL mark gives a "stamp of approval" to the safety and quality of a product, establishing customers' trust and confidence. Firms can utilize UL certification in communications to assure that they back a guarantee of safety and excellence, distinguishing themselves as distinctive in a competitive market.

Key Considerations for Getting UL Recognition

When referring to PCBs for UL recognition, following factors are important to consider:

Flame Classification: Establish the end-product application to determine the minimum acceptable flame class. UL classifications V-0, V-1, and HB are helpful in ensuring maximum performance and safety with respect to the product environment.

Maximum Operating Temperature (MOT): It is the measure of maximum continuous operating temperature at which a circuit board can function. Reporting this measure based on end-product requirements provides reliability in long-term use, offering maximum functionality.

Minimum Comparative Tracking Index (CTI): CTI testing on laminate material measures resistance to electrical tracking, which is essential for safety and longevity. Selecting materials with appropriate CTI ratings guarantees products are less susceptible to electrical failure.

Direct Support (DSR) Conformity: Confirmation that material meets DSR specifications, i.e., performance in contact with the present-carrying components at specified voltages, is required to maintain safety at reduced voltages.

Number of Soldering Operations: Due to the widespread use of Surface-Mount Technology (SMT), PCBs need to withstand multiple reflow processes to ensure ruggedness in the complex soldering processes required for modern assemblies.

UL marking of PCBs is required for supplying safe, reliable, and quality printed circuit boards. Compliance with UL standards demonstrates a manufacturer's commitment to producing electronics that not only comply but also exceed safety expectations. With growing demand for innovative yet trustworthy electronic products, leveraging UL certification as a major differentiator supports market positions, fosters consumer trust, and allows for ongoing innovation within safety limits. Through UL marking, manufacturers can safely assure their customers the quality and safety of their technologically advanced products, opening doors to success in the highly competitive electronics industry.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

CTI measures PCB material's resistance to electrical tracking, ensuring safety and reliability in electronic circuits, crucial for design and manufacturing.

PCB test coupons simulate board elements for reliability checks, detecting early issues to ensure quality and performance before mass production.

Solder masks protect PCBs from damage and solder bridging. Available in various types and colors, they ensure reliability. Eco-friendly options and precise thickness measurements are crucial for quality.