Wave Soldering Fixture Design for Optimal PCB Assembly

Wave soldering fixtures are crucial for achieving precise through-hole PCB assembly, minimizing defects, and enhancing overall manufacturing efficiency.

The modern electronics world has become very competitive thus accuracy in the manufacturing processes is a requisite to manufacture high quality products. The technique is essential especially in through-hole technology (THT), as wave soldering is a crucial technique that is used to assemble reliable solder joints on printed circuit boards (PCBs). The focal point of this process optimization is the wave soldering position often referred to as a wave solder pallet.

Wave Soldering Fixtures: The Importance

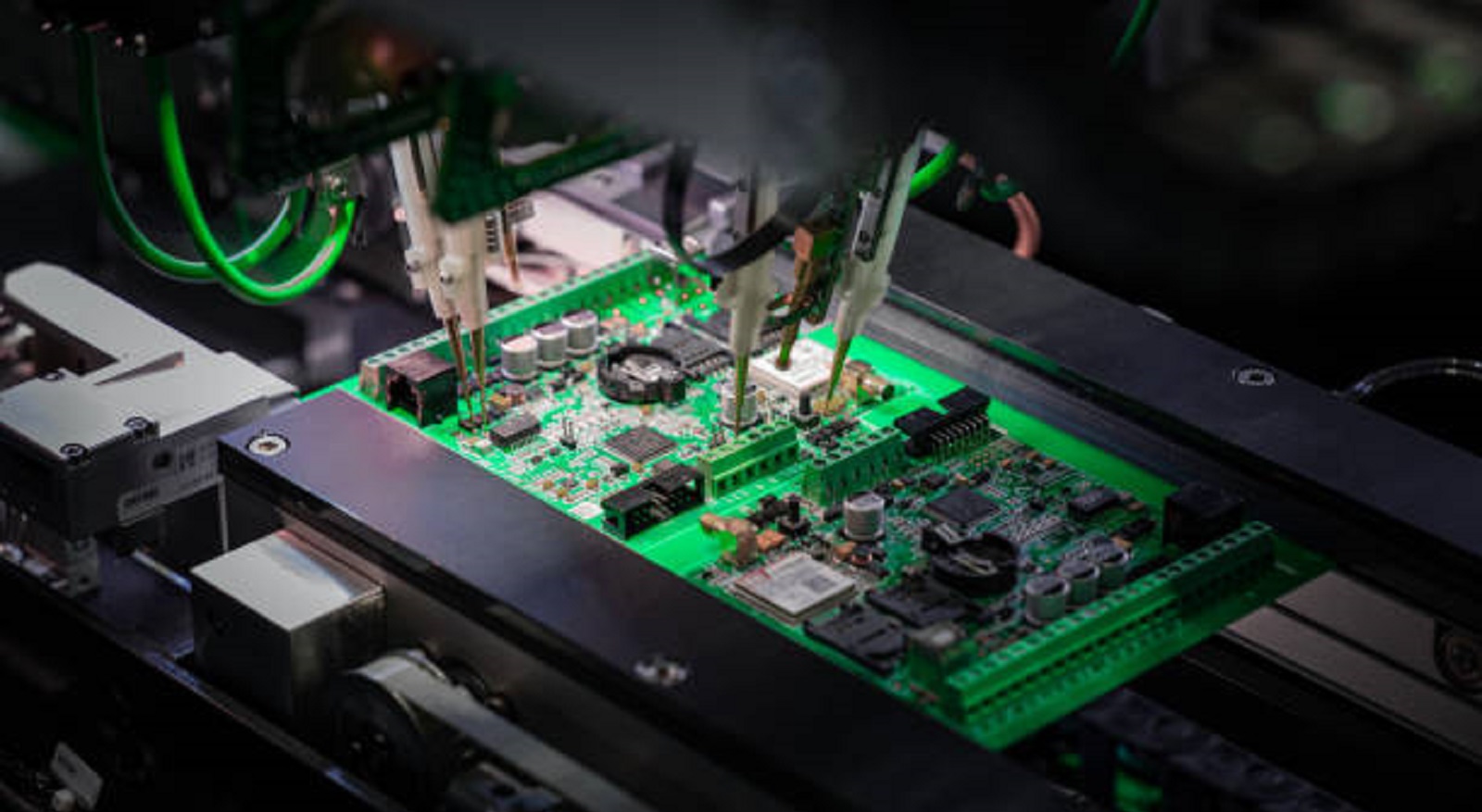

Wave soldering fixtures are instruments that hold the PCBs in place as the solder wave passes, and only certain parts of PCBs are exposed to the solder wave. This biased exposure is critical to PCBs that combined surface-mount devices (SMDs) and THT, as it shields the delicate components and regions against unwanted solder contact. Faults like solder bridges, thermal stress, and damaged parts can be greatly minimized through proper designing of the fixtures leading to increased manufacturing efficiency and manufacturing yield. Such companies as PCBX have understood the importance of these fixtures in enhancing the precision and reliability in soldering.

Basic Rules of Designing Fixtures

Masking and Component clearance

It is important to pay attention to the clearance of components in the design of fixtures in order to prevent interference with a solder wave. Stereotyped items like electrolytic capacitors require deeper holes in the fixing to avoid exposure to the wave. Having a 2-3mm clearance surrounding the parts that are essential serves as a method of safeguarding the components and keeping them in place during the soldering process.

Secure Board Alignment

PCBs have to be firmly attached in fixtures to avoid misalignment during the soldering process. This is by including alignment pins or edges that align with the reference points of the PCB with accuracy especially in high density boards. It is important to such precision to avoid soldering mistakes and to guarantee the functionality of circuits.

Solder Wave Access

Openings and strategic cutouts are to be placed at the points where the PCB is to be soldered, whereas the shielding areas are to be covered by SMDs and pre-soldered components. The selective exposure is crucial to ensuring uniform high quality soldering.

Stability and Durability of Fixtures

To achieve stability of the fixtures, it is necessary to make the base flat and evenly distribute weight in such a way that the items would not tip over or shake on the conveyor system of the soldering machine. Given that fixtures are reused over several cycles, it is necessary to select materials that would not be subjected to warping, and could withstand mechanical stress, increasing the life cycle of the fixtures.

Choosing the Right Materials

The choice of material has a great effect on wave soldering fixtures performance, durability, and cost. Common materials include:

ESD-Safe Composite Materials: They are popular due to their superior thermal resistance and electrostatic discharge ability, and can withstand temperatures up to 300degC allowing them to be used in the lead free soldering operations.

High-Temperature Plastics: These are inexpensive, lightweight, and they can be used to work with normal soldering temperatures, but may not be as durable as composites.

Aluminum: Aluminum is known to be durable; it is commonly covered to avoid sticking of solder. Nevertheless, it has a high thermal conductivity that it should be insulated well.

Ceramics: Ceramics are brittle and expensive, but offer better heat resistance to special purposes.

Management of Thermal in Fixed Light Design

To avoid damages to PCB or component, it is important to solve thermal problems:

Heat Resistance: The material of the fixture should be able to resist deformation or degradation at the high temperatures that are present during wave soldering, and normally between 240℃ and 260℃ in the case of lead-free processes.

Thermal Conductivity: Thermal conductivity is a property of materials that allows heat to flow through them, therefore appropriate insulation should be taken to avoid unintentional heat flow.

Heat Dissipation: Ventilation channels on fixtures will help in the distribution of heat evenly, and reduce hot spots that can be damaging to the board or components.

Preheating Compatibility: The fixtures are supposed to have the ability to preheat gradually without distorting hence being reliable during the soldering process.

Managing Costs

To balance between cost and quality, one needs to take into account a number of aspects:

Complexity of Material and Design: Design can be simplified without compromising performance costs can be reduced. Composite material can be used to strike a balance between performance and cost.

Volume of Production: High-volume runs enjoy the advantage of investing in durable materials though this could be costly to purchase initially but could be economical in the long run.

Reusability: The life of the furniture will affect its total cost-efficiency in which a properly designed furniture will give an advantage in terms of costs when the cycle of production is spared.

Best Practice in Manufacturing

Precision in manufacturing incorporates a number of practices that entail:

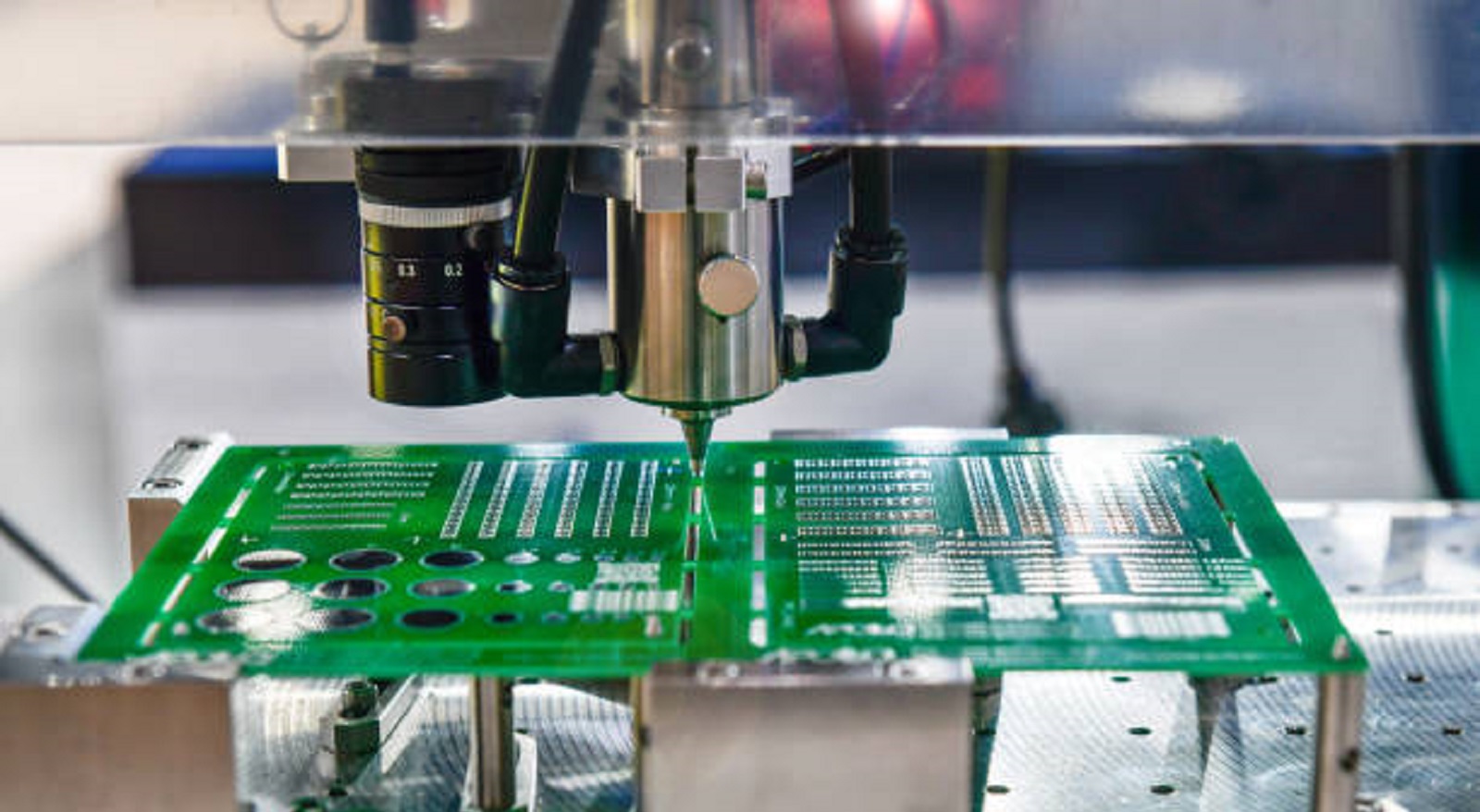

CAD Design and CNC Machining: The technologies help to achieve high accuracy, and the design tolerances are tight to achieve efficient functionality of the fixtures.

Material Preparation and Finishing: To provide better durability of the soldering environment, defect-free materials can be used and proper coating is to be applied.

Testing and Validation: Prototype testing, This is to make sure that the design is adequate to proceed to full scale production, to make sure that it fits, aligns, and performs thermally and that it produces high quality results.

Addressing the Most Typical Obstacles

Solder Bridging: This defect can be avoided by making sure the cutouts on the fixtures are accurate and the solder machine settings are controlled to regulate the solder flow and the creation of joints.

Thermal Warping: Low thermal expansion materials and a homogenous design of the fixings should be used in order to spread the heat evenly so that there is a low chance of the fixings becoming warped.

Fixture Wear and Misalignment: Fixed inspections and strong alignment capabilities can be used to keep the efficacy of the fixtures in the course of time.

Wave soldering fixtures are important instruments in the attainment of excellent PCB assembly results particularly in boards where the components are through holes. Through fine material choice, intelligent design, effective thermal control, and cost wise planning, PCBX can create fixtures which will boost the output of soldering. It is important to customize the solutions of a given PCB project and fit the challenges. Using the concepts mentioned in this guide, business organizations can transform their PCB assembly routines to a higher level where they can guarantee a consistent, reliable and high-quality output of outcomes every time they engage in a production process.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Wave soldering is vital for assembling printed circuit boards (PCBs), aiming to bond electrical components. The process involves passing PCBs over a wave of molten solder to form connections. Common defects include pin/blow holes, solder shorts, poor hole fill, lifted components, excessive solder, solder balling, and solder flags. To address these issues, key factors include proper flux application, controlled preheat temperatures, optimal solder wave settings, and careful material handling. Understanding and managing these factors ensures high-quality, reliable PCB assemblies.

Wave soldering is a PCB assembly process that moves the board over a molten solder wave to create reliable connections. Evolving from dip and drag soldering, it offers consistent, high-quality solder joints. Despite its complexities, it remains essential for through-hole components and complex PCB assemblies.

Soldering forms a very important part in the assembly of a PCB. Wave soldering is ideally applied in Through-Hole Technology, while reflow soldering in Surface Mount Technology. Wave soldering involves flux spraying, pre-heating, soldering, and cooling, while in the case of reflow soldering, pre-heating, thermal soak, soldering, and cooling steps are applied. Temperature and time control are the two most critical parameters in the above-mentioned techniques for ensuring soldering reliability.