What is DFM Check?

In PCB manufacturing, DFM Checks ensure efficient production by identifying design issues early, reducing costs, enhancing quality, and preventing delays.

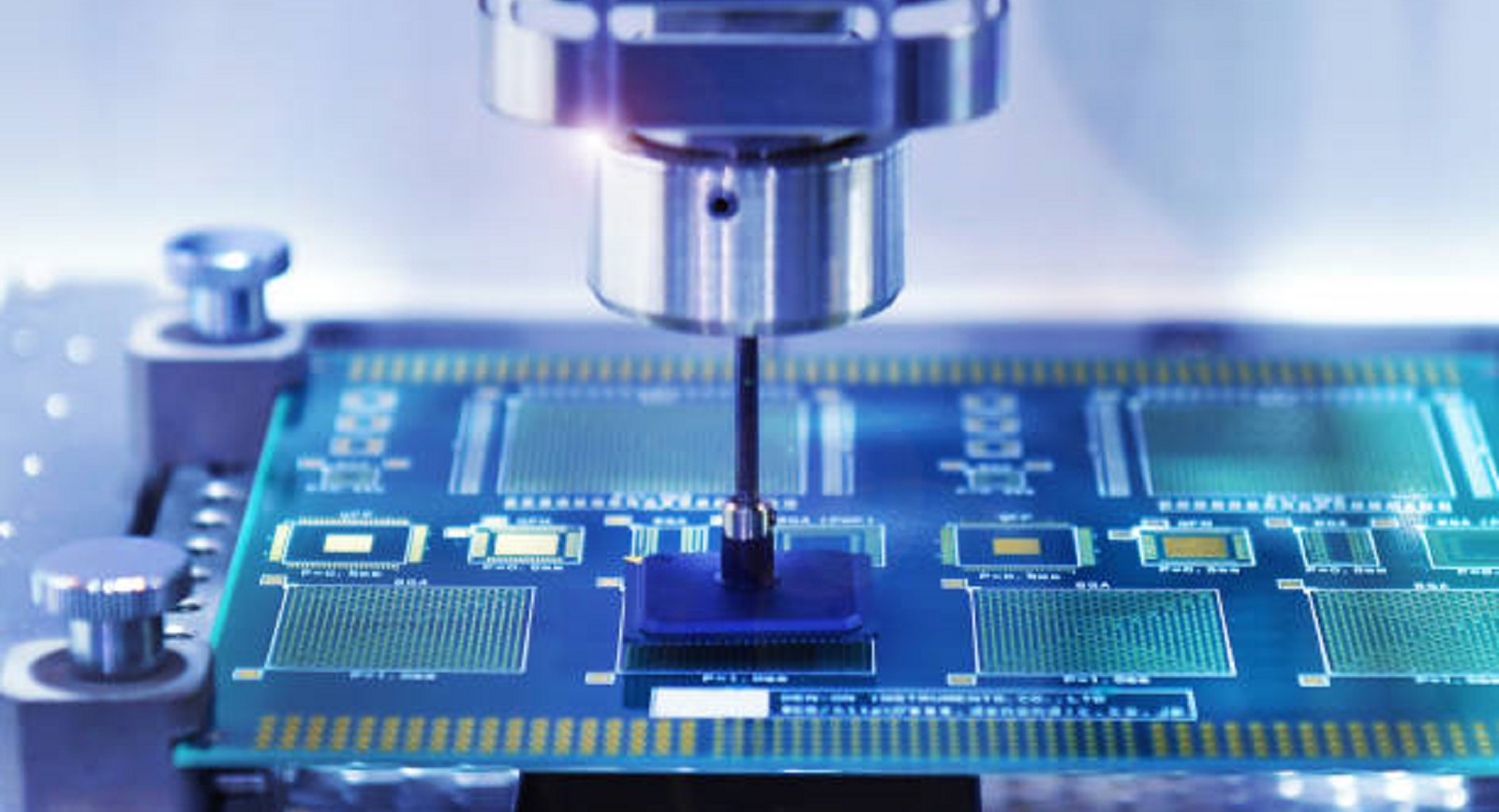

In the high-speed manufacturing world, specifically in the PCB industry, it is crucial that products be designed to be produced most efficiently. This is where Design for Manufacturability (DFM) Checks come in. At PCBX, we pay attention to detail when it comes to the production process and the necessity of DFM to streamline processes and reduce costs. In this guide, we go in-depth on what a DFM Check is and why it is so crucial in the world of PCBs.

Introduction to DFM Checks

DFM, or Design for Manufacturability, is an engineering process segment that guarantees products are designed to be produced efficiently at low cost and high quality. A DFM Check refers to a methodical examination of a product design to identify and solve potential manufacturing issues before it is manufactured, minimizing interruptions and expenses.

The Significance of DFM Analysis

DFM analysis is not just beneficial but also vital, reaping several benefits:

Cost Savings: It is much less expensive to correct and resolve design issues at the early design phase than after production. Correction early on can prevent expensive changes.

Defect Prevention: Production reproduces design defects in all the units, leading to continued defects. DFM Checks are a preventive measure to detect such flaws early.

Avoiding Delays: A design that is not correct may result in reworks, which can postpone production. DFM analysis facilitates fixing those issues in advance, avoiding time loss.

Enhancing Quality: A solid DFM process translates to higher assembly success rates, fewer scrapped parts, and reliable product quality.

Enhanced Manufacturability: Designing with consideration for the manufacturing capabilities results in easier production processes.

These benefits are the reason why leading engineering teams prioritize DFM Checks before moving designs to the production floor. The ROI in preventing manufacturing problems is high.

Timing of DFM Checks

In order to maximize the benefit of DFM, it must be applied during the design and development cycle:

Conceptual Design Phase: Applying DFM Checks at the beginning ensures the design direction is inherently moving in the direction of manufacturing best practices.

Detailed Design Phase: Complete DFM checks are carried out after finalizing the design to verify production readiness.

Design Revisions: Design revisions later require a new DFM analysis to ensure new issues aren't introduced.

Including DFM as a continuous process throughout development, and not as a final step, enables the detection and correction of issues early, preventing costly changes in later stages.

Major Areas Analyzed in a DFM Check

A DFM Analysis of PCBs examines several critical aspects:

Tolerances and Clearances: Ensuring component tolerances are within established limits and electrical and physical clearances are adequate.

Draft Angles and Surface Finishes: Ensuring draft angles and surface finishes are appropriate for manufacturability.

Hole Sizes and Alignments: Ensuring hole diameters are to standard and include plating allowances.

Fastening Considerations: Establishing the acceptability of fastening and joining mechanisms for PCB assembly.

These parameters are key to pre-empting and solving manufacturing issues ahead of time, and thereby ensuring quality.

DFM Principles and Guidelines

There are certain underlying principles that form the basis of the DFM process:

Simplicity and Intuition: Designs should be as simple and intuitive as can be, with the least amount of complexity.

Error Proofing: Incorporate features that minimize the risk of assembly errors, such as guides and asymmetry.

Standardization: Use standard components and processes wherever possible to make manufacturing easier.

Process Abilities: Maintain designs within existing manufacturing capabilities to promote efficiency.

Modularity and Streamlining: Design with modularity and streamline parts wherever possible to minimize the process.

Manual vs. Automated DFM Checks

DFM analysis can be conducted manually or with automated systems:

Manual Checks: Relies on experienced veteran engineers to visually inspect designs, simulate assembly sequences, and utilize their experience to detect issues. Informative but may be time-consuming and subject to human error.

Automated Checks: Utilize software tools to automatically detect common design issues such as poor clearances or tolerance violations. Efficient but cannot fully replace the sophisticated judgment of veteran engineers.

A combination method, utilizing automated software to highlight possible issues for further manual analysis, yields the best results.

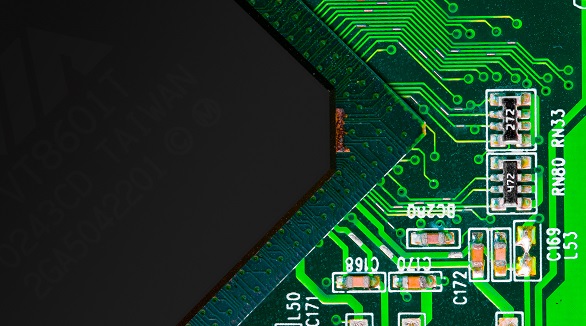

Fixing DFM Violations

Designers fix design flaws through modifications after identifying them with the use of DFM Checks:

Changing Tolerances and Dimensions: Alter tolerances and dimensions to align with the process capabilities.

Reworking Design Features: Modify surface finishes, draft angles, and hole sizes as necessary for manufacturability.

Simplifying and Optimizing: Simplify complex geometries and optimize assembly sequences for operational efficiency.

Many small changes can often accumulate to enhance manufacturability without the need for redesign.

A well-implemented DFM Check is essential for optimizing PCB manufacturing. By integrating DFM best practices into each design phase, manufacturers can reduce cost, enhance product quality, and accelerate time-to-market. At PCBX, it is our goal to implement total DFM strategies to manufacture products that are top class and efficiency. By leveraging the insights and strategies outlined in this guide, organizations can enhance their manufacturing capabilities, avoid costly pitfalls, and remain competitive in an ever-evolving market.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

DFM ensures cost-effective PCB design by optimizing size, layers, materials, and components, focusing on manufacturability, reliability, and process efficiency.

Tab routing enhances PCB production efficiency and quality, ideal for complex shapes. It offers cost-effectiveness, flexibility, and protection, crucial for high-precision designs and panelization.

Design for manufacturability (DFM) in PCB production ensures quality, reliability, and cost-effectiveness by optimizing component selection, placement, trace routing, materials, and testing, leading to reduced costs, better products, and faster market entry.