What is FPC Connector?

FPC connectors enable miniaturization and reliability for flexible circuits, crucial in electronics, automotive, and medical applications, enhancing functionality and design.

As with the rapid-paced world of electronics, where both consumer expectations and technological potential are constantly evolving, the demand for miniaturization and increased functionality continues to be the impetus for innovation. Flexible Printed Circuit (FPC) connectors, which play the pivotal role in achieving this, have emerged at the focal point as obligatory devices in modern electronic engineering. They are trusted options to industry requirements for reduced size, weight reduction, and overall interconnect flexibility. As such, they are an indispensable part across an extremely wide variety of applications.

The Role and Importance of FPC Connectors

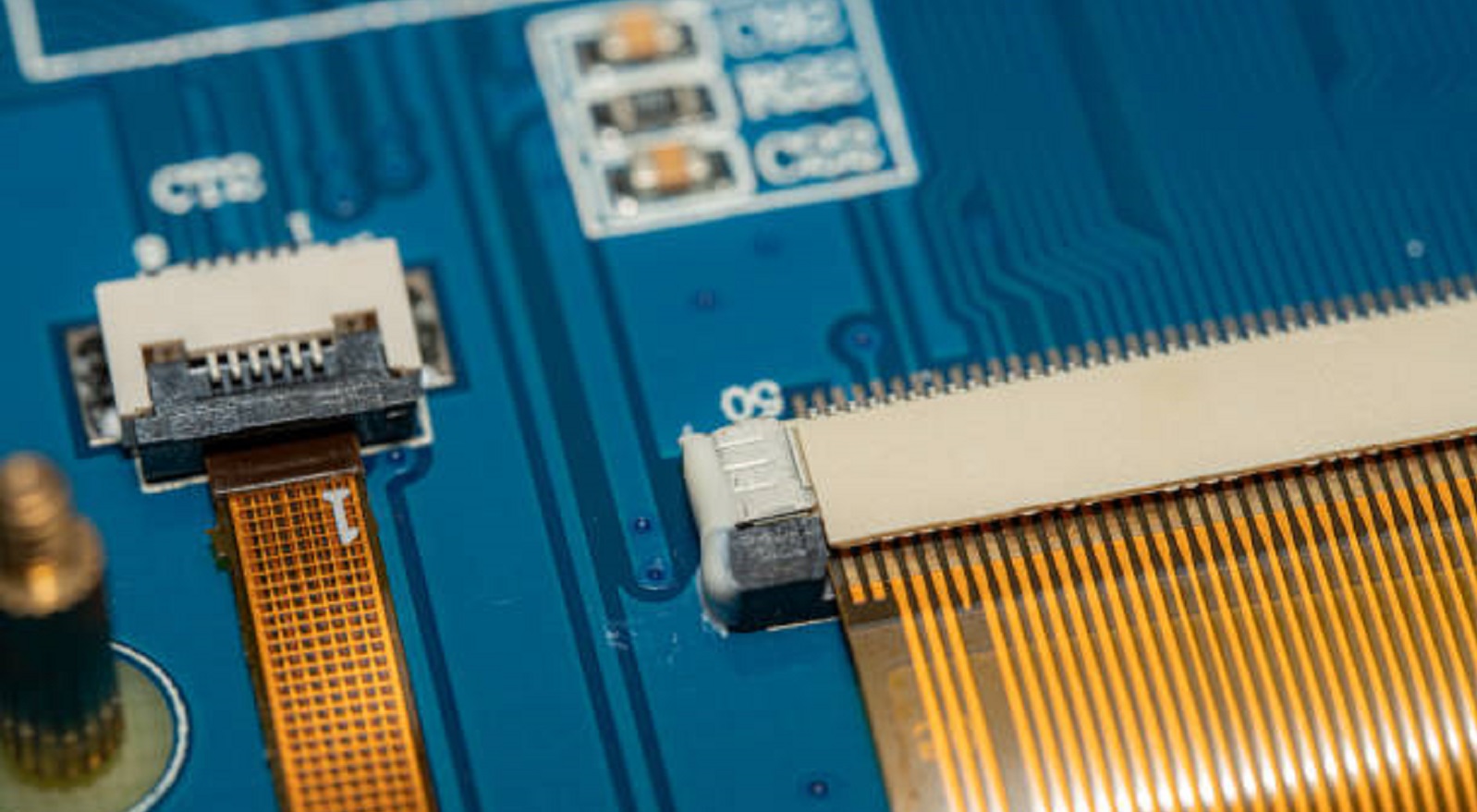

Flexible Printed Circuit connectors are employed for the joining of flexible circuits to other electronic components or printed circuit boards. They are critical to applications that require limited space and the need to save weight in parts. Accuracy in printed circuit board solutions is what is important to PCBX, and we value the contribution FPC connectors make towards bridging the gap between rigid and flexible circuitry, hence allowing for groundbreaking device designs and overall performance enhancement.

Key Features and Specifications

FPC connectors are intended to offer a combination of miniaturization, reliability, and the convenience of integration. Some of their core attributes are:

Broad Pitch Range: Available in a range of interface sizes, including 0.25mm, 0.3mm, 0.5mm, 1.0mm, and 1.25mm. The range supports a variety of applications, offering design engineers options to enable compatibility with diverse configurations of devices.

Compact and Low-Profile Design: In line with the trend of miniaturizing devices, FPC connectors are low-profile in design to provide easy integration into low-profile space-limited environments without compromising performance.

Ease of Termination: Connectors are field-friendly, simple-to-terminate connectors that do away with the need for special tools to terminate, providing ease of manufacture and repair.

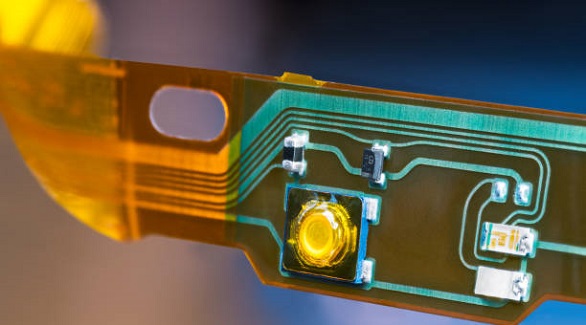

Durability: Although FPC connectors have a low profile design, they are built of heavy-duty materials that ensure connection stability and long lifespan even under repeated movement or vibration.

Applications and Versatility of FPC Connectors

Versatility of FPC connectors has ensured their application in a diverse array of applications:

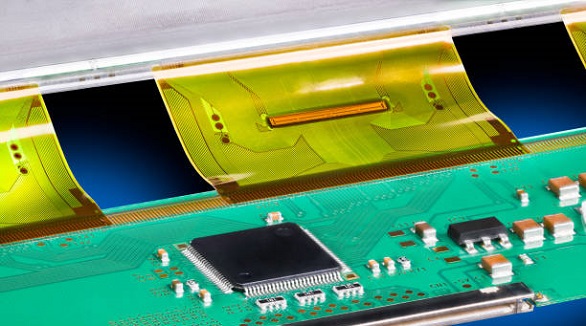

Consumer Electronics: FPC connectors are a part of the functionality of tablets, smartphones, laptops, and cameras. They offer connections between batteries, displays, and other modular components so that devices can be both small in size and functional.

Automotive Systems: FPC connectors in vehicles are used in new systems such as in-vehicle infotainment, ADAS, and smart lighting systems. Their design is adapted to be tolerant of the harsh environment of the automotive industry, providing stable connections in areas of vibration and temperature fluctuation.

Medical Devices: In medical technology, where miniaturization and reliability are paramount, FPC connectors are central to the development of wearable patient monitors and tiny diagnostic devices that enhance patient care and medical diagnostics.

Industrial and Networking Applications: 5G technology deployment and smart manufacturing have put FPC connectors in the limelight. They make next-generation applications possible and help build next-generation industrial solutions.

FPC vs. FFC Connectors

A common misconception creeps in while distinguishing between FPC connectors and Flexible Flat Cable (FFC) connectors. While both are used for identical purposes of circuit interconnection, they are vastly different in terms of construction, flexibility, and scope of usage:

Construction: FPC connectors are a blend of printed or embedded circuitry in a flexible base with flexibility of complex circuit topology. FFC connectors are, however, flat cables with metal tips parallel to the substrate for straightforward applications.

Flexibility and Thickness: FPCs are generally thinner and more flexible in profile, best suited for extremely constrained locations with a demand for dynamic flexing. FFCs are more robust and frequently utilized for applications requiring higher rigidity and conductor protection.

Incompatible Substitution: Used similarly, but FPCs and FFCs cannot be directly substituted for one another due to differences in manufacturing processes and performance profiles. Both perform specialized functions appropriate for specific design and application needs.

Types of FPC Connectors

For various application requirements, FPC connectors come in various types such as:

Single-Layer Circuits: Single-side circuits that are low-cost to produce and well-suited for basic applications where complex multilayer connections are unnecessary.

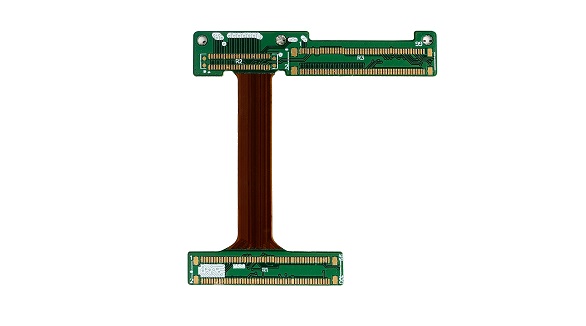

Dual-Layer Circuits: These exhibit greater complexity and flexibility to allow designers to implement more complicated circuitry within a limited form factor.

Multilayer Circuits: With three or more layers, they support intricate designs, but cost more to produce. They allow for very compact, high-performance electronics.

As electronic equipment becomes smaller and more capable, the application of FPC connectors becomes increasingly important. Their ability to seamlessly integrate flexible and rigid circuitry allows them to be an essential element of modern electronic design. At PCBX, our dedication to what can be accomplished with PCB solutions only emphasizes our admiration for FPC connectors and their increasing ability. They are not only well able to meet current demands of technology but also future aspirations, further emphasizing their place as one of the foremost contributing elements in electronics' development. As technologies develop, the demand for high-performance, cost-effective interconnection solutions like FPC connectors will increase inexorably, opening the door for further development in the field of electronics.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Flexible solder masks offer cost-effective flexibility, while coverlays provide durable protection for FPCs, catering to different application needs.

Flex PCB thickness affects performance, offering flexibility, compact design, and durability but demands careful material selection and precise engineering.

Flex PCBs fit into devices, saving space, while Rigid-Flex PCBs combine flexible and rigid parts, ideal for varied applications. PCBX offers custom designs, rapid prototyping, and high-quality manufacturing.