PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

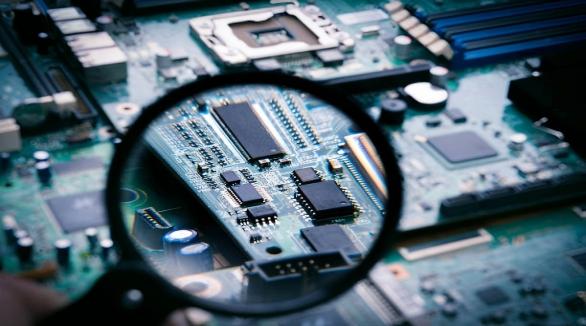

AOI uses cameras and software to automatically inspect PCBs for defects, ensuring high quality, reducing costs, and improving reliability in modern PCB manufacturing.

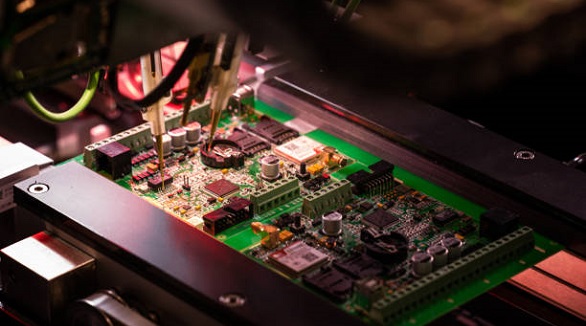

Choosing between manual and automated PCB assembly depends on production volume, with manual assembly ideal for prototypes and automation best for high-volume runs.

Common PCB assembly defects, their root causes, and proven prevention methods are outlined to improve reliability, yield, and manufacturing efficiency.

Professional PCB cleaning prevents corrosion and failure, typically using 99% IPA to safely remove flux residue while maintaining component integrity.

PCBs form the foundation of electronics; standard PCBs offer cost-effective simplicity, while advanced PCBs cater to high-performance and precision requirements.

Proper trace-to-pad clearance in PCB design ensures safety, signal integrity, manufacturability, and longevity, following standards like IPC 2221 for optimal performance.

PCB thickness is essential for device performance, impacting signal integrity, thermal efficiency, and durability, thus requiring careful selection for optimal outcomes.

01005 components are key for miniaturization in electronics, requiring precise handling in PCB assembly to overcome challenges in soldering, placement, and inspection.