What is Keyboard PCB?

Custom mechanical keyboards use PCBs to connect components and enable customization. Enthusiasts can tailor layouts, repair, upgrade, and modify keyboards for a personalized typing experience.

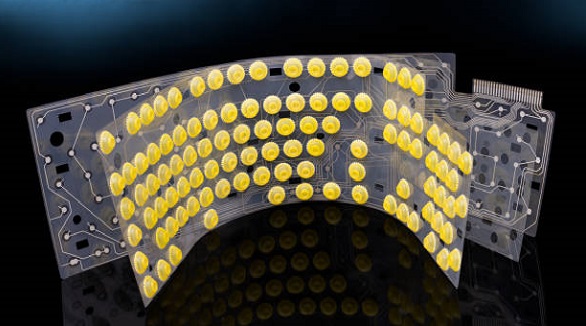

In recent years, custom mechanical keyboards have enjoyed great popularity among enthusiasts looking for personalized typing experiences. At the core of every keyboard-from mass-manufactured models down to bespoke creations-lies the PCB, or Printed Circuit Board. This integral component will define, not only the functionality of the keyboard in question, but also the possibility of customization that it offers. But what is a Keyboard PCB, really? Let's examine its anatomy, functionality, and its place within the keyboard ecosystem.

A Keyboard PCB or Printed Circuit Board is basically an insulation-based flat board hosting a network of conductive pathways. These pathways, for the most part, connect different components of the keyboard, including switches, diodes, resistors, microcontrollers, and at times even LEDs. The PCB backbones the entire keyboard unit, translating each mechanical keystroke into an electronic signal the computer can understand and use.

Components of a Keyboard PCB

Switch Sockets/Pads: These are the locations pre-marked on the PCB where mechanical switches are mounted. Each pad on the PCB designates the position of a key on the keyboard.

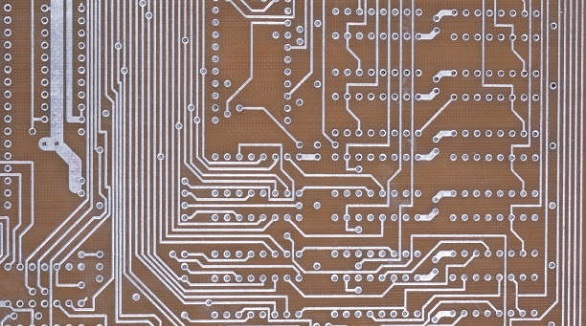

Traces: These are thin conductive pathways that connect the various components of the PCB, facilitating easy communication between the switches and the microcontroller.

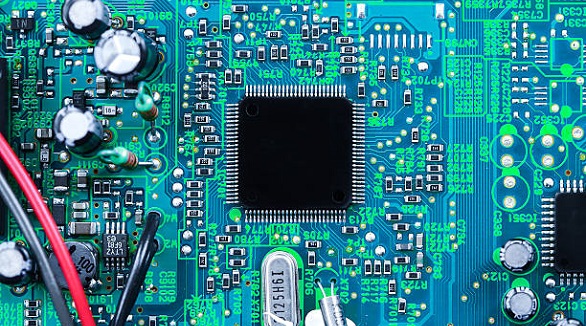

Microcontroller: This will be the brain of the keyboard PCB: it processes the key presses and relays corresponding signals to the computer. The microcontroller can also deal with secondary functions, such as lighting or the recording of macros.

Diodes: These are usually deployed to avoid "ghosting." Diodes permit the flow of current in one direction, thereby avoiding incorrect interpretations of key presses.

LEDs and RGB Support: Some PCBs even include LEDs or support RGB lighting for adding custom backlighting or under-glow effects.

Types of Keyboard PCBs

Standard vs. Hot-Swap

Standard PCBs rely on soldering when it comes to the installation of switches. Once soldered into place, switches are securely fastened and would need to be desoldered in order to be replaced or changed.

Hot-Swap PCBs have switches that can be installed and removed easily without soldering, offering flexibility for users who enjoy changing switch types frequently.

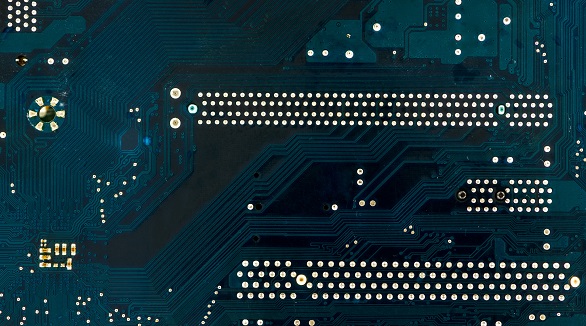

Single Layer vs. Multi-layer

Single-Layer PCBs have one side with components and are simpler in design, used for simpler keyboard builds. Multi-layer PCBs have more complex designs that allow compact layouts and advanced functionalities.

Custom vs. Pre-made Layouts

Custom PCBs are designed to realize unique keyboard layouts or individual user preferences. These include customized key placements and features. Pre-made layouts are standardized and mass-produced for common keyboard configurations.

Benefits of Keyboard PCBs

Customization: Knowing your PCB means being able to tailor a keyboard layout, switch types, and additional features according to personal typing habits and aesthetic preferences. Repair and

Maintenance: A good understanding of the PCB will easily facilitate repairs or modifications that improve the longevity and functionality of your keyboard.

Upgrades and Modifications: For those who take pleasure in tinkering with keyboards, knowing how to replace parts, add RGB features, or even build macro keys is simple.

Far more than a simple electronic component, the keyboard PCB forms the bedrock on which a keyboard is built. Be you an enthusiast looking to try your hand at a custom build or simply a curious individual looking to understand how your device works, a basic understanding of keyboard PCBs can open a whole new world of possibilities. With a deep understanding of this critical component, users can unlock the full potential of their mechanical keyboards by tailoring them precisely to their needs and enhancing their overall computing experience.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Select aluminum PCBs for excellent heat management or FR4 PCBs for cost-effective versatility in diverse electronic applications.

Effective PCB design ensures reliable electronics by optimizing component placement, connections, and testing, enhancing performance and longevity.

Motherboard PCBs are crucial for organizing and connecting components in electronics, ensuring efficient performance. They require detailed design and testing to meet reliability and functionality standards.