PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Transistor inverter circuits are vital in converting digital signals and limited power sources into reliable energy, enabling consistent performance in various applications despite power outages.

Testing diodes with a multimeter is crucial for ensuring reliable performance and preventing failures in electronic appliances by directing current flow effectively.

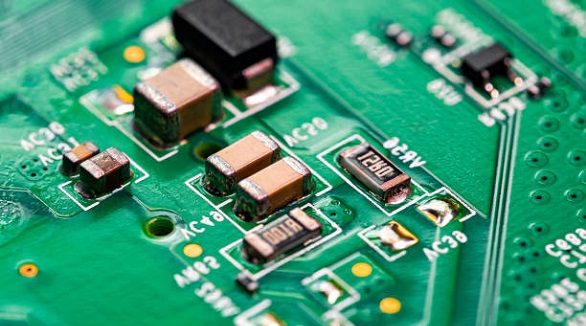

PCB tombstoning, caused by uneven soldering due to factors like pad design and component placement, disrupts circuits but can be mitigated through precise control and optimization.

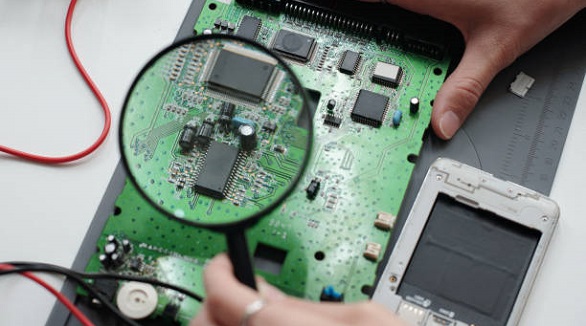

Serial numbers on PCBs are crucial for traceability, quality control, warranty support, and inventory management, ensuring compatibility and efficient device management.

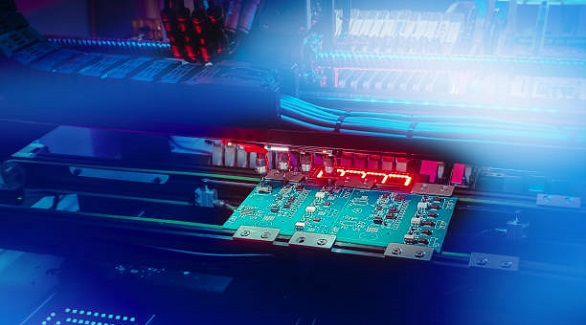

Battery Protection PCBs ensure safety by preventing overcharge, over-discharge, and short circuits, crucial for efficiency in modern rechargeable devices.

Mounting power supplies on PCBs optimizes space, reliability, and performance. Key factors include layout, thermal management, and mounting methods.

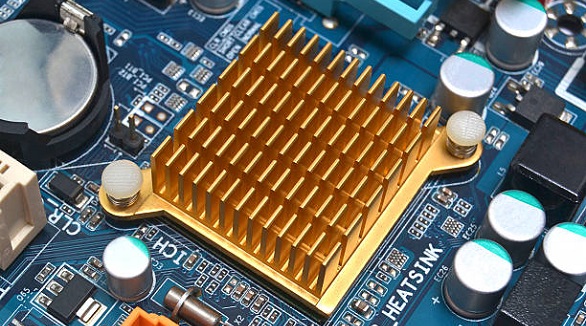

Heat sinks are essential for reliable PCB design, managing heat in high-density components like transistors and LEDs, ensuring optimal performance.

Preheating PCBs enhances soldering by reducing thermal shock, improving wetting, and activating flux, using methods like conduction, convection, and IR.