4-Layer PCBs

4-layer PCBs optimize space, performance, and cost, making them ideal for electronics requiring reliable and compact designs, such as in consumer electronics, telecom, and automotive.

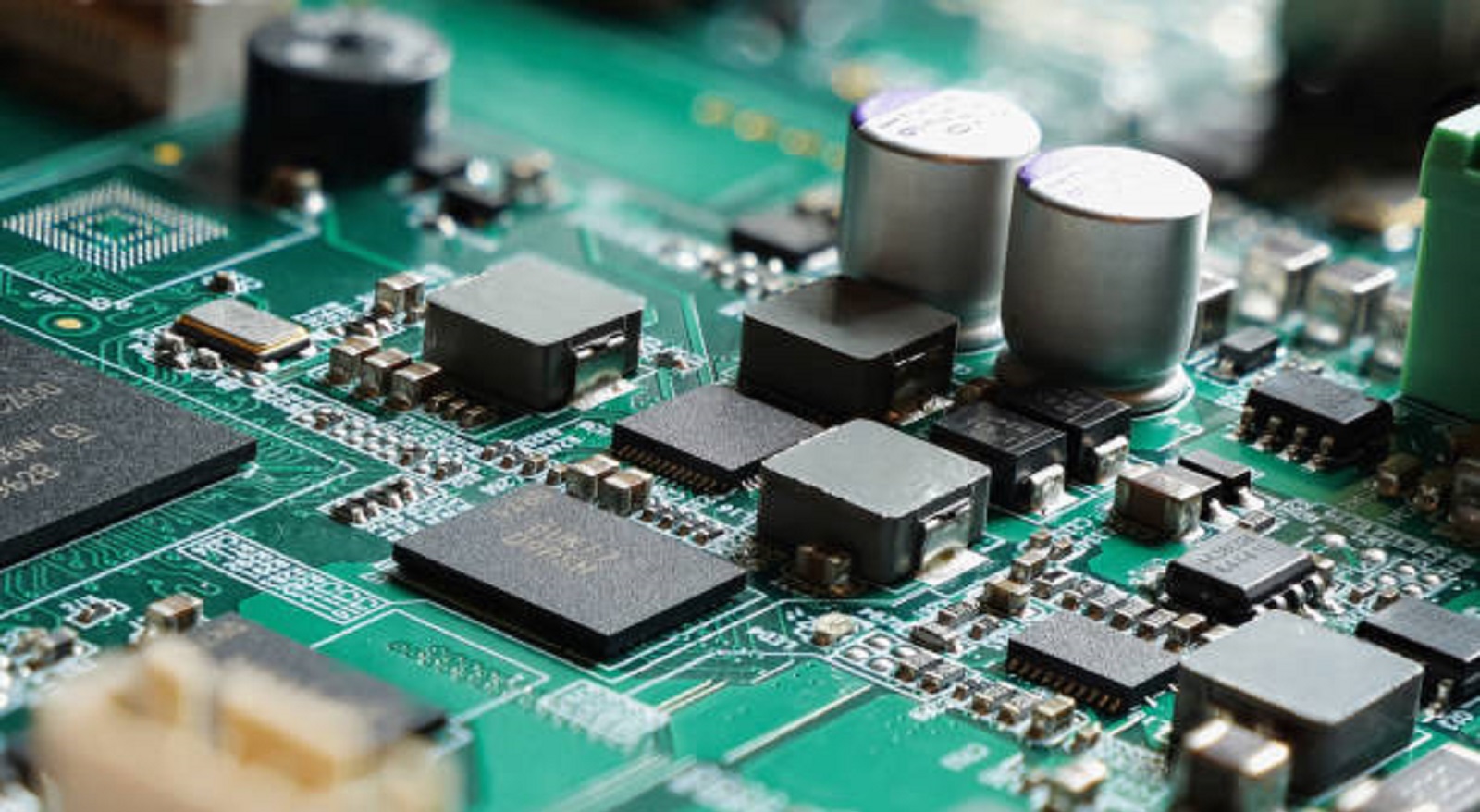

In the rapidly developing field of electronics, Printed Circuit Boards are the very basic framework behind connecting and energizing modern devices. Among these different available multi-layer options for PCBs, 4-layer PCBs have become popular due to their capability to provide compactness with superior performance and reliability without increasing the cost. This detailed discussion involves the basics of 4-layer PCB: construction, advantages, applications, and best design and manufacturing practices.

What is a 4-Layer PCB?

A 4-layer PCB is a complex board of electronic circuitry with four layers of conductive material, usually copper, separated by insulating dielectric material. It is a configuration that allows for more intricate circuitry and greater functionality within its scope, yet without occupying much physical space. The general arrangement consists of a top layer, two inner layers, and a bottom layer.

Top Layer (Signal Layer): This is mainly used for the routing of signals and component placement. Due to the main circuit functions, a solder mask is usually laid over this layer to avoid oxidation and to provide easy soldering.

Inner Layers-Power and Ground: These layers usually host the VCC and GND planes to optimize the distribution of power and reduce EMI noise. At times, they also serve in routing additional signals whenever needed by a design.

Bottom Layer (Signal Layer): Like the top layer, it too serves in signal routing and can also carry surface-mounted components, reinforcing that the circuit is complex and capable.

The construction often uses fiberglass-reinforced epoxy resin, or FR4, appreciated for its robust strength-to-weight ratio, excellent thermal resistance, and dielectric properties.

Advantages of 4-Layer PCBs

The advantages of using a 4-layer PCB are many:

Improved Signal Integrity: The availability of dedicated power and ground planes significantly reduces electrical noise and interference for better signal integrity. This becomes important in high-speed applications and precision electronics where performance cannot be compromised.

Miniaturization Capabilities: Additional layers offer designers the ability to fit more complex circuits into smaller form factors. This capability is increasingly important as consumers demand portable, multi-functional devices with advanced features.

Improved Thermal Management: The multi-layer structure allows better dissipation of heat, hence improving thermal management. This reduces potential risks from overheating, hence prolonging the lifespan of components and ensuring consistent performance.

Higher Component Density: The 4-layer design supports increased component density by allowing engineers to implement multiple trace routings without intersection conflicts. This results in efficient usage of space and resources, fostering innovation without inflating costs.

Reduced EMI: The internal dedication of power and ground planes naturally shields against EMI, protecting the performance and reliability of vulnerable electronic devices.

Applications

4-layer PCBs find their perfect application in many industries for the right balance of complexity, cost-effectiveness, and performance:

Consumer Electronics: Smartphones, tablets, and wearables use 4-layer PCBs to enable compact, efficient circuit solutions that support a wide range of functionalities in a portable format.

Telecommunications: In such telecommunications equipment as routers and network switches, 4-layer PCBs provide the necessary signal integrity with reduced interference to support the high data transmission speeds required.

Automotive Electronics: Modern vehicles now contain advanced systems, including ADAS, infotainment units, and ECUs. The robustness and miniaturization that the 4-layer PCBs offer enhance these systems, which ensure safety, entertainment, and performance.

Medical Devices: Multilayer PCBs support the demands for precision and reliability for medical diagnostic and monitoring devices, powering innovations in healthcare technologies.

Industrial Equipment: Automation systems and control units intended for harsh conditions require 4-layer PCBs to offer durability and effectiveness for their operation in industrial equipment.

Design and Manufacturing Best Practices

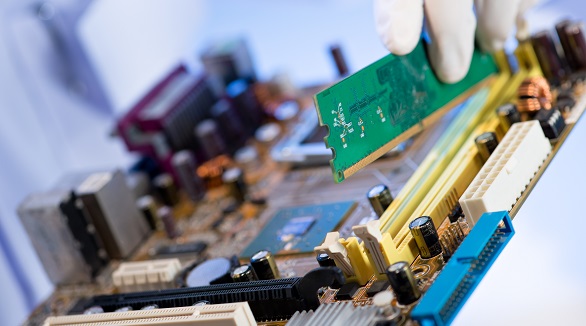

Designing a 4-layer PCB requires attention to some principles that ensure efficiency and effectiveness:

Layer Utilization: Assign power and ground to inner planes to mitigate noise and enhance the reference continuity. The outer layers should be reserved for signal traces and component layout.

Routing Strategy: Route critical signal paths, including high-speed signals, in order to minimize crosstalk and EMI. Consider using advanced routing techniques such as length tuning and differential pair routing for more complex designs.

Via Management: Place vias optimally to reduce parasitic effects and enable reliable connectivity. Too many vias increase capacitance and inductance, which can affect performance.

Thermal Considerations: Design with thermal management in mind, using appropriate materials and layouts to ensure efficient heat dissipation.

At PCBX, we make sure that design principles like these form part of our manufacturing processes. We offer solutions customized according to your specific needs, making sure that each and every PCB meets the highest standards of quality and reliability.

The 4-layer PCB represents a remarkable leap in the electronics industry in balancing performance, cost, and spatial optimization. As technology advances relentlessly and creates demand for even more sophisticated devices, 4-layer PCBs are bound to remain important in electronic design and manufacturing. Understanding design principles, advantages, and applications that 4-layer PCBs provide gives more meaning as to how modern electronic systems are structured to perform effectively. Partnering with PCBX provides an advantage by availing the best-quality and most innovative 4-layer PCBs for the electronics manufacturing industry. Now, take full advantage offered by 4-layer PCBs to confidently move your projects forward by meeting the evolving technological demands of today with excellence and innovation.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Copper weight determines PCB effectiveness in conductivity, thermal management, and mechanical strength, essential for high performance in various applications.

3-layer PCBs offer a balance of cost and complexity with benefits like improved signal integrity, reduced EMI, and increased component density for varied applications.

10 oz copper PCBs offer high current capacity, improved thermal management, and durability for demanding applications in power electronics, aerospace, and military.