Applications and Types of PCBs in Automotive Industry

PCBs are essential in modern cars, enhancing performance, safety, and connectivity across systems like ADAS and infotainment, while facing design challenges.

In modern automobiles, Printed Circuit Boards (PCBs) are now essential components. From transforming traditional mechanical automobiles to state-of-the-art electronic systems, PCBs enhance performance, safety, and connectivity. This piece addresses the primary uses, design challenges, and specialized types of PCBs that are applied in the automotive industry, indicating their pivotal role in shaping future automotive technology.

PCB Applications in Automotive

PCBs are at the core of a multitude of automotive systems, aiding in both fundamental operations and cutting-edge technological functionalities. Some of the significant areas of application are:

Powertrain Control: Critical to the control of engine and transmission operations, PCBs assist in controlling engine performance, fuel efficiency, and emissions control. Some key components are engine control units, transmission control modules, battery management systems, and traction inverters and converters, highlighting the requirement for high-quality PCB design.

Advanced Driver-Assistance Systems (ADAS): As vehicles inch towards autonomy, ADAS systems, underpinned by PCBs, translate information from cameras, radar, and LiDAR electronics. These integrations yield adaptive cruise control, lane-keep assist, and automatic emergency brake features, boosting safety and user convenience immensely.

Infotainment Systems: PCBs drive in-car entertainment and connectivity in infotainment head units. They power navigation systems, audio amplifiers, telematics gateways, and graphics display to provide seamless experiences for drivers and passengers.

Body Control Systems: PCBs manage lighting, door modules, HVAC systems, and central gateway ECUs. These operations deliver comfort and enhance energy efficiency as well as vehicle reliability.

Instrument Clusters: New vehicles utilize PCBs in instrument clusters to provide odometer operation, driver information display, and warning lights operation. Such systems offer valuable information, improving safety and awareness of the situation.

Security Modules: The core of vehicle security lies in PCB control of immobilizers, central locking, and blind spot detection, improving vehicle safety and security.

PCB Design Challenges in Automotive

PCB design for automotive use requires overcoming a number of challenges based on the harsh environments they must support. Some of the major challenges are:

High Vibration/Shock Loads: PCBs have to withstand heavy vibrations and shocks from engines and road surfaces, and therefore need rugged design techniques such as component bonding and board stiffening to ensure survivability.

Temperature Extremes: Automotive PCBs run in environments from -40°C to 125°C, and therefore need proper material selection and component placement to counteract thermal stress.

Electromagnetic Interference (EMI): EMI from motors, actuators, and RF devices needs to be minimized. Controlled impedance routing and excellent shielding design characteristics are vital in maintaining signal integrity.

High Voltages: Especially in electric vehicles, PCBs must be capable of handling voltages up to 650V and transient conditions like load dumps, with very robust power distribution design and comprehensive safety measures.

Mixed Signal Circuits: Integration of analog and digital circuits requires meticulous partitioning and layout to prevent cross-circuit interference.

Safety and Reliability: Compliance with standards like ISO 26262 and rigorous validation procedures is critical to ensure reliability and safety of automotive PCBs.

Key PCB Design Considerations

PCB designs meet industry requirements by incorporating specific considerations:

Component Selection: Employing automotive-grade components AEC-Q101 qualified over long temperature ranges ensures performance in harsh environments.

Layout Design: With minimum creepage and clearance distances per ISO 6469-3, with significant safety layout separation to avoid shorts and failure.

Power and Signal Integrity: Establishing solid power planes and controlled impedance routing enables effective power and signal integrity management.

Thermal Management: High-temperature-rated materials such as polyimide are used, and thermal vias and slots allow for heat dissipation.

Vibration Resistance and Conformal Coating: Techniques like component bonding, underfills, and encapsulation enhance resistance, and conformal coatings shield from environmental stressors.

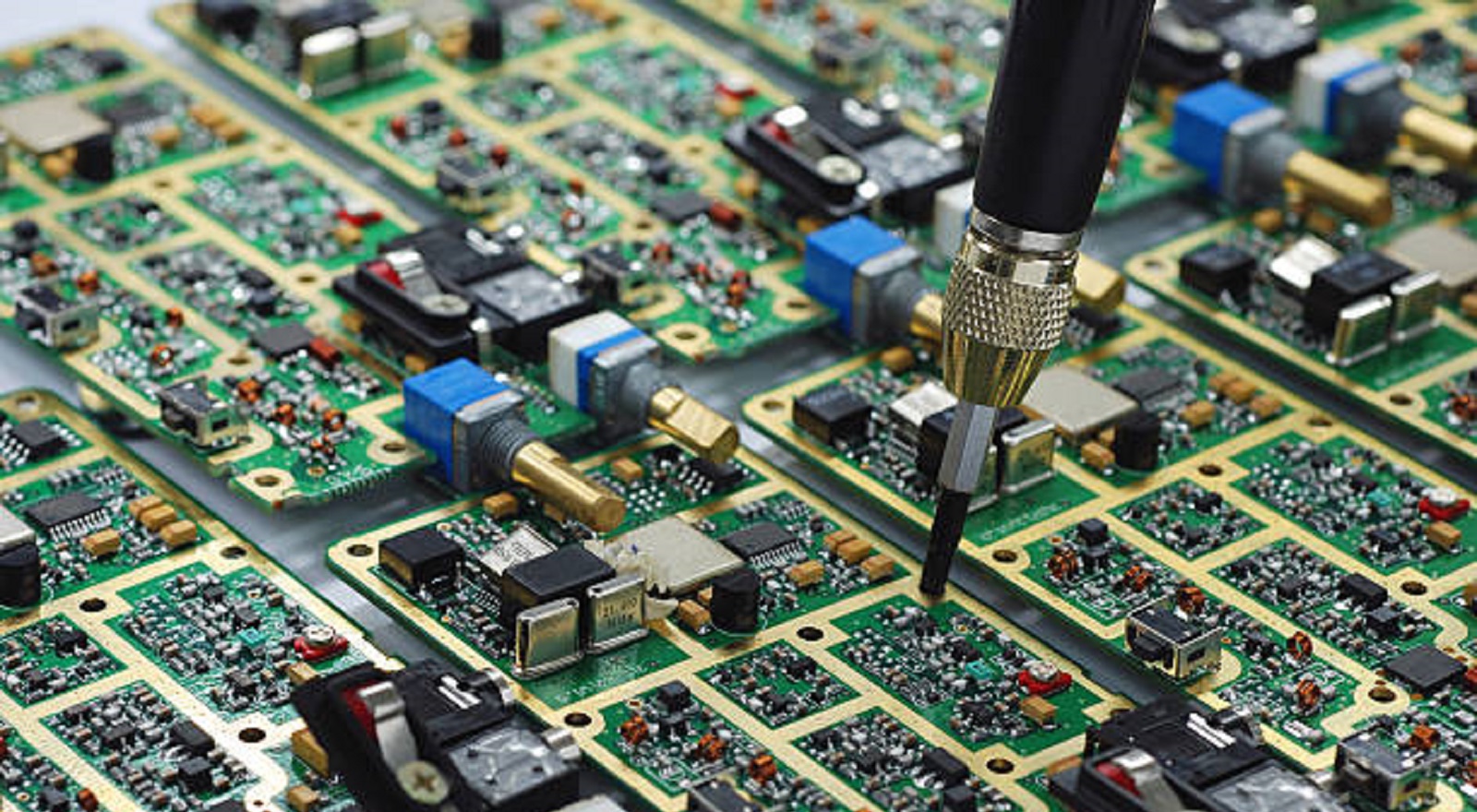

Types of PCBs Used in Automotive

The automotive industry employs various types of PCBs to meet particular demands:

Rigid PCBs: Known for their strength, they employ higher Tg materials to perform well under demanding conditions.

Flexible PCBs: Ideal for space-constrained applications, they offer flexibility and are constructed using materials like polyimide for high-temperature flexibility.

Rigid-Flex PCBs: A hybrid of rigid and flexible sections, these PCBs offer complicated routing and interconnect different components with ease.

Metal Backed PCBs: Used for improved heat dissipation and EMI shielding, they are essential in high-power applications.

High Frequency PCBs: For RF circuit designs, these PCBs offer controlled impedance for applications like collision avoidance systems.

New Automotive PCB Trends

Emerging technologies keep pushing automotive electronics:

High-Density Interconnect (HDI) PCBs: HDI technology enables integrated function with additional routing layers and microvias, creating the possibility for more complex applications.

Advanced Dielectrics and Additive Processes: Emerging technologies like high thermal conductivity dielectrics and additive manufacturing processes, such as aerosol jet printing, enhance PCB performance.

Embedded Passives and Panel Level Packaging: The integration of passive components into PCBs saves space and increases performance, and panel-level packaging allows integrating the PCB with other components in a convenient way.

PCBs permeate modern vehicles, allowing for functionality from powertrain control to ADAS systems. Conquering design challenges requires expertise in disciplines like signal integrity and thermal management. With the trend toward further electrical integration, innovation in PCB materials and fabrication processes will be critical to advancing next-generation vehicle technology. PCBX is at the forefront, delivering advanced PCB solutions engineered to meet evolving needs of the automotive sector.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Electromechanical parts assembly integrates mechanical and electronic components for optimal device function, vital in modern PCBs and tech innovation.

Industries rely on electrical power control systems for efficient energy use, safety, and sustainability, crucial for productivity and technological integration.

IoT revolutionizes interactions and efficiency with 30B devices by 2025, requiring secure data exchange and smart integration across various industries.