PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

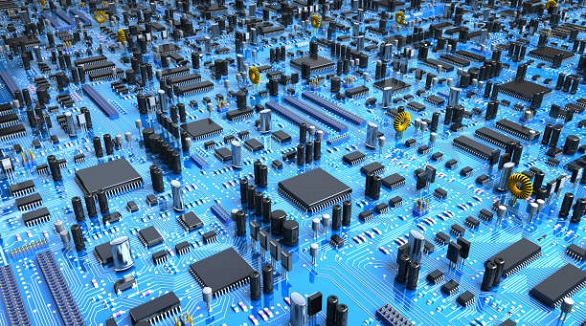

PCB panelization improves productivity, reduces costs, and facilitates automation by assembling several smaller PCBs into one large panel, ensuring uniformity.

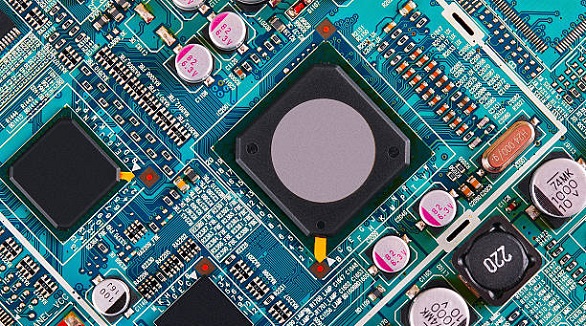

Lifted pads disrupt PCB performance due to thermal and mechanical stress. Solutions involve better design, materials, and handling to ensure reliability.

PCBs are crucial in transforming energy grids into smart, efficient systems, optimizing renewable integration and energy management for a sustainable future.

Panelization combines multiple PCBs on one panel, boosting efficiency and cost-effectiveness in manufacturing by optimizing space and enabling automation.

Tab routing in PCB manufacturing boosts efficiency and quality, ideal for non-linear shapes, offering flexibility, support, and cost-effectiveness in production.