Basics of Hand Soldering and Components

Soldering is vital for connecting components on PCBs in electronics, employing techniques like hand, wave, and reflow soldering to ensure reliable assemblies.

Soldering is a critical skill in the electronics industry, a link between paper design and functioning circuitry. Soldering is a technique admired both for its technical precision and its beauty. Whether received by enthusiasts or as a commercial occupation, soldering is very important to learn. The article below covers the basics of hand soldering and the key elements involved, and has a focus on Printed Circuit Boards (PCBs).

Understanding Soldering

Soldering is metal piece joining with a filler metal—solder. It is a general process necessary for making both the electrical contact and mechanical integrity available in electronic assemblies. Although there are varying processes, the end goal remains the same: making a stable connection through melting two metals of differing substances using solder. Standard solder is made of tin and lead alloys, or as a result of environmental pressure, lead-free compounds. The solder gets melted on contact with the hot soldering iron, acting in a similar way to glue in keeping different PCB components together effectively.

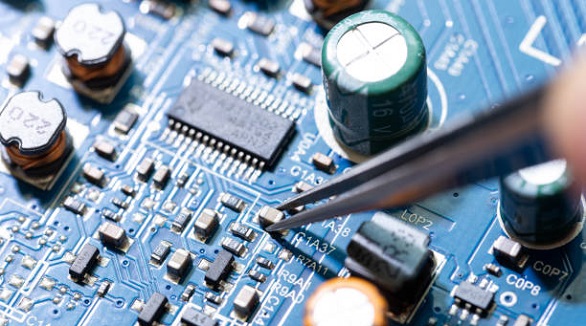

Nature of PCBs and PCBA

PCBs form the backbone of nearly all pieces of electronic gear. PCBS consist of conductive paths built from copper foils laminated on a non-conducting base material. PCBA refers to the process by which such boards are populated with electronic components. PCBS and PCBAs are vital components found in consumer electronics used in everyday life such as mobile phones, routers, and computers, and also in key industries such as automotive, telecommunication, medical, defense, and aviation.

Soldering Process Types for PCB

Three fundamental soldering processes are used in PCB assembly:

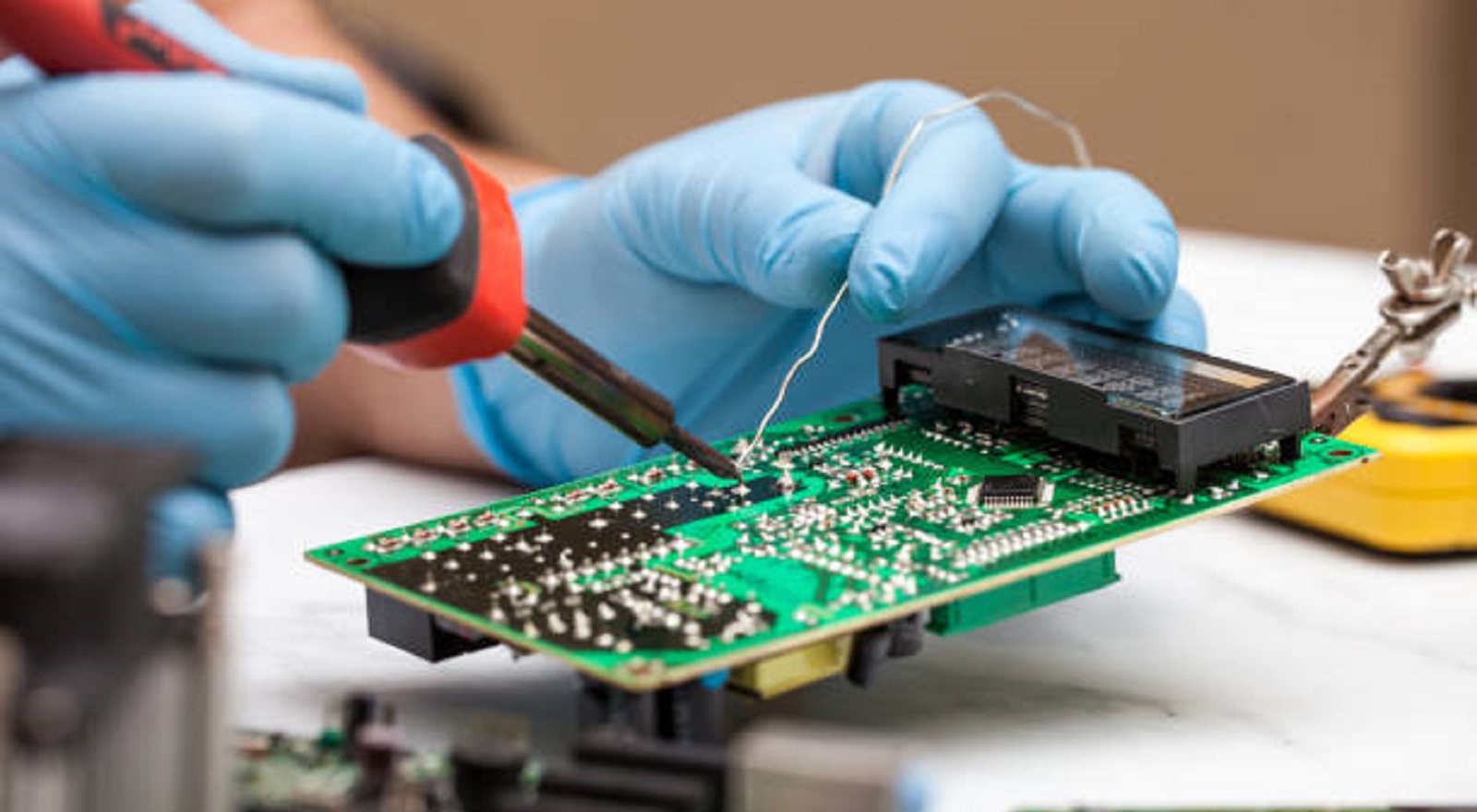

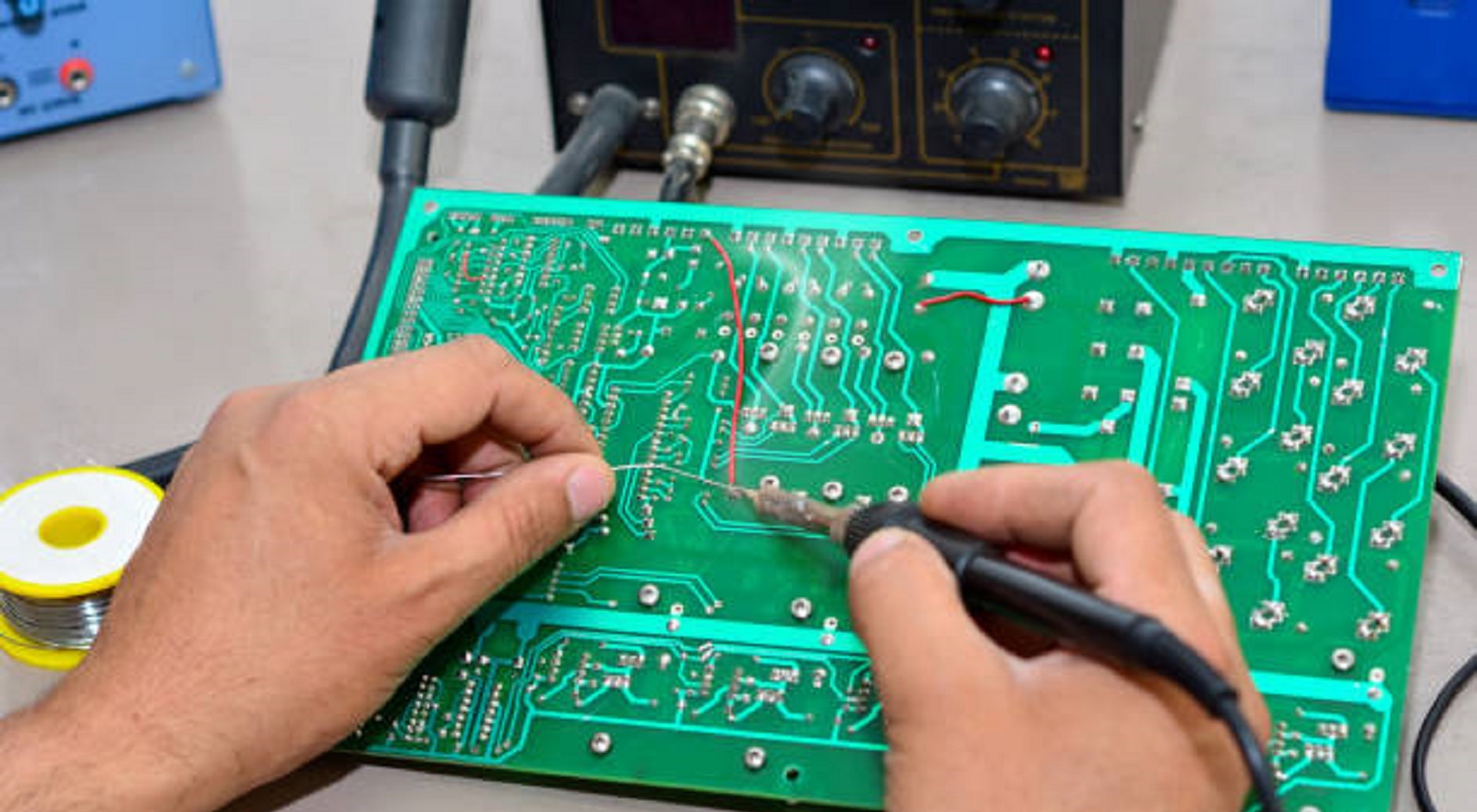

Hand Soldering: A human-factored method involving a soldering iron, ideal for delicate work, prototyping, and low-volume production.

Wave Soldering: PCBs are transported across a wave of molten solder, commonly used for through-hole components in high-volume production.

Reflow Soldering: Automated heat is controlled to melt solder paste, mounting surface-mount devices cost-effectively, particularly for high-volume production.

Immersive Analysis of Hand Soldering

Hand soldering remains a valuable skillset for technicians and engineers, especially in rework, repair, or during the handling of components that are challenging for machines to deal with. Often termed as "soft soldering," the method employs temperatures below 400°C to protect temperature-sensitive components from harm. While simple to execute, it requires delicate technique and knowledge of Surface Mount Technology (SMT) and Through-Hole Technology (THT) both.

Strengths of Hand Soldering:

Provides accurate control, hence suited for complex tasks.

Suitable for small-sized projects and correcting assembly errors.

Disadvantages of Hand Soldering:

Not suitable for components with high thermal requirements.

Time-consuming and less reliable for bulk production compared to automatic techniques.

Key Hand Soldering Equipment

Soldering Iron: Adjustable heat equipment, required for solder melting.

Solder: Typically an alloy utilized as material for joining.

Desoldering Tools: Required for adjustments.

Safety Equipment: Goggles and fume extractors to safeguard the user.

Steps Involved in Hand Soldering

Preparation and Safety:

Begin by properly cleaning the PCB and component leads to remove contaminants that could inhibit solder adhesion. Gather all tools to be utilized, including a soldering iron with an appropriate wattage range (15W-60W), solder wire, and safety gear such as goggles and a fume extractor.

Component Placement:

Inserticic components into the holes of the PCB, bending the leads at 45 degrees in order to keep them held in position before soldering. The components must be aligned well and snugly fitted into their positions. This is very critical as errors in placement can lead to the circuit failing.

Preparing the Soldering Iron:

Melt and tin the soldering tip with fresh solder and flux in order to transfer the heat effectively and prevent oxidation. It enhances the tip lifetime and the quality of the solder joint.

Applying Heat and Solder:

Hold the iron tip on both the component lead and PCB pad and heat them enough so that the solder can flow freely in the joint. Solder around the joint but not on the iron tip to permit even distribution and a good joint.

Completing the Solder Joint:

Remove the heat and allow the joint to cool gradually by itself. Avoid relying on the joint physically while it is cooling to prevent the establishment of a brittle, insecure bond. Trim off excess leads and inspect the joint for anything unusual such as imperfect adhesion or cold spots.

Quality Assurance:

Verify that no incomplete or cold joints are left behind through thorough inspection. Use other instruments such as magnifiers to assess the quality of solder joints.

Soldering is a sought-after skill within electronics that enables components to be assembled smoothly on a PCB. Whether made by hand soldering or using automated methods such as wave or reflow soldering, knowledge of each process's nuances ensures robust and effective electronic assemblies.

At PCBX, excellence in PCB manufacturing underscores the importance of mastering these essential skills. From novice to seasoned engineers, enhancing soldering techniques can have a direct impact on the performance and reliability of electronic devices. With technology advancing every minute, expertise in soldering ensures a permanent connection between innovation and feasible application, necessitating the requirement for dependable, high-performance electronic assemblies. Whether you’re creating prototypes, making repairs, or working on a production line, cultivating skill in hand soldering will enhance both your capabilities and the quality of your electronic projects.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Dry solder joints in PCBs cause unreliable connections, leading to device failure. Prevent with proper heat, cleaning, quality solder, and skilled techniques.

Master soldering chip components on PCBs using proper tools and techniques, ensuring precision and reliability for both hobbyists and professionals in electronics.

Solder masks protect PCBs, while paste masks aid precise component placement during assembly, both crucial for PCB reliability and efficiency in electronics.