PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

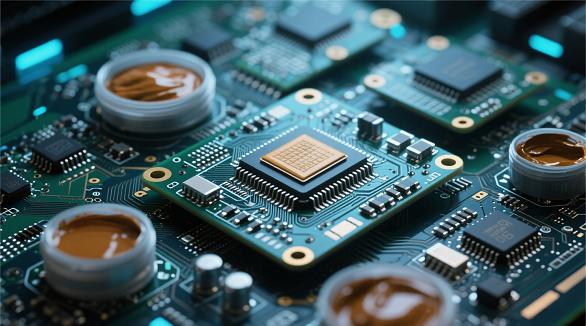

Selecting the right solder wire, with consideration for composition, flux type, and diameter, is crucial for creating reliable electronic connections in both hobbyist and professional settings.

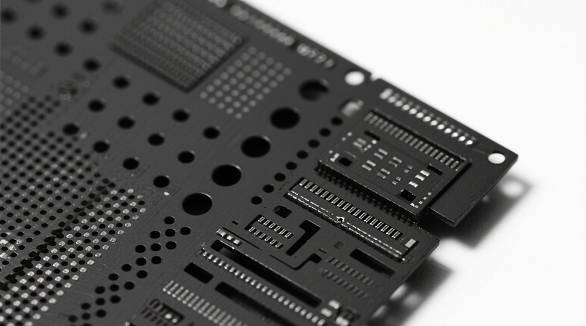

Step stencils optimize solder paste for varying component sizes in PCBs, enhancing reliability and reducing defects in complex designs with precision.

Selecting the right solder paste for PCB assembly is crucial for connections and industry standards, balancing compliance, performance, and productivity needs.

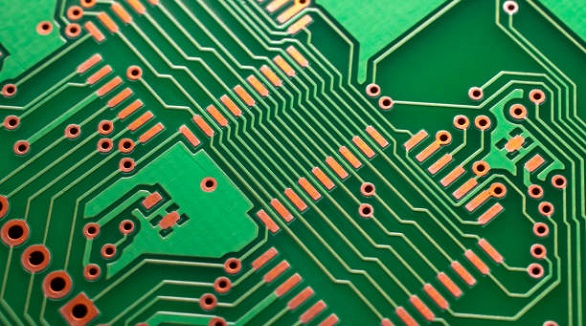

SMT footprints are critical PCB designs for mounting components directly, ensuring electrical connections and standardization, aiding efficient manufacturing.

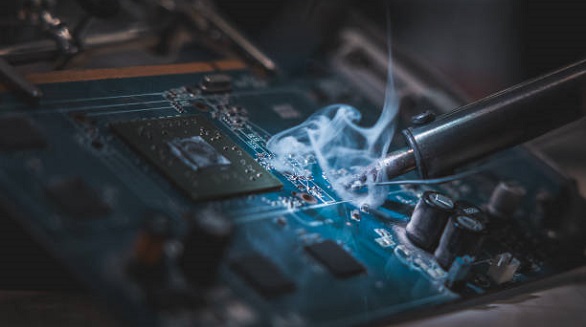

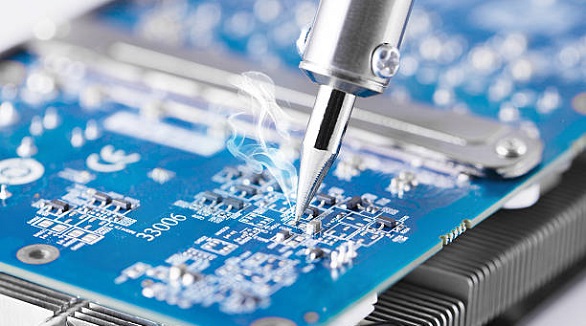

Soldering is vital for connecting components on PCBs in electronics, employing techniques like hand, wave, and reflow soldering to ensure reliable assemblies.

PTH soldering provides strong connections by threading component leads through PCB holes, requiring meticulous preparation and quality checks for lasting results.

Dry solder joints in PCBs cause unreliable connections, leading to device failure. Prevent with proper heat, cleaning, quality solder, and skilled techniques.

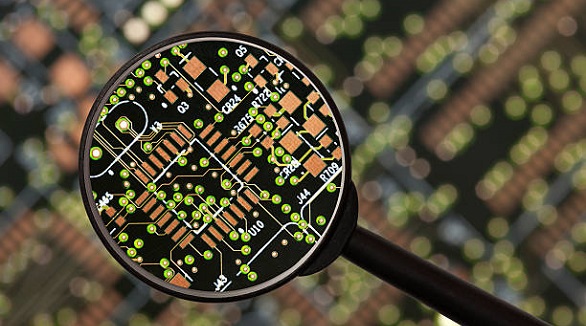

Controlled impedance is crucial in modern PCBs, ensuring signal integrity through precise trace and material design, essential for high-speed applications.