Solder Paste Types for PCB Assembly

Selecting the right solder paste for PCB assembly is crucial for connections and industry standards, balancing compliance, performance, and productivity needs.

In the intricate world of electronics production, solder paste selection is critical to providing consistent printed circuit board (PCB) assembly. As a PCB electrical engineer, the right selection of solder paste provides excellent connections and satisfies industry expectations. We at PCBX understand these intricacies and look to provide our clients with the best solutions appropriate to their own unique needs. This article explores solder paste forms, their characteristics, applications, and impact on assembly process to allow you to make informed decisions.

Why Solder Paste is Required in PCB Assembly

Solder paste is the cornerstone of modern PCB assembly, especially in surface-mount technology (SMT). It acts both as an adhesive to hold components in place and as a conduction material to form reliable electrical connections. An incorrect choice can lead to issues like weak joints, tombstoning, or voids that will compromise the integrity of your circuits. Having a grasp of the nuances of solder paste selection can mean the difference between a successful project and rework costs.

Solder Paste Key Components

It is wise to understand solder paste composition prior to discussing particular types. Solder paste is a mixture of flux and metal alloy particles. The alloy contributes melting points and mechanical strength, while the flux influences cleanliness ease and residue formulation. They form various solder paste categories, each for a specific application.

Solder Paste Types

Lead-Free Solder Paste: A Contemporary Standard

Lead-free solder paste is used as a standard in the industry, particularly post the 2006 Restriction of Hazardous Substances (RoHS) directive. The lead-toxic paste is shunned, and alternative alloys are employed. SAC305 is the most commonly used lead-free alloy and is made up of 96.5% tin, 3% silver, and 0.5% copper. Its melting point is around 217-220°C, slightly higher than the original leaded solder (183°C for Sn63/Pb37).

Advantages: RoHS and eco-friendly; very high mechanical strength suitable for applications requiring high reliability like automotive and aerospace.

Disadvantages: Stresses on heat-sensitive components as a result of higher melting points; more prone to tin whiskers, causing shorts in fine-pitch constructions.

Best Use Cases: Consumer electronics imperative, medical devices, and products that are distributed in regions where environmental regulations are strict. For instance, SAC305 offers compliance and maintains joint strength over thermal cycling for smartphone PCB assembly.

No-Clean Solder Paste: High Volume Production Efficiency

No-clean solder paste is designed to result in very minimal residue, and therefore, cleaning after reflow is not necessary. The no-clean paste has an inert flux when heated, leaving a non-corrosive residue. No-clean paste's flux is inert at heat, forming a non-corrosive coating. Comprising generally rosin or synthetic resins, this type is applied extensively in high-volume production due to its efficacy.

Advantages: Saves money and time in production by not including the cleaning process; suitable for high-volume production.

Challenges: Residues can impede conformal coating adhesion or in-circuit testing if not managed well; not ideal for harsh applications where residue can pose long-term threats.

Best Use Cases: Ideal for consumer products, e.g., mass assembling Internet of Things devices. Using no-clean paste can decrease production time significantly by eliminating the necessity for cleaning stations.

Water-Soluble Solder Paste: Offers Immaculate Cleanliness

Water-soluble solder paste uses flux that can be readily cleaned using deionized water after reflow. The flux would be organic acid-based, which has great wetting but has to be washed away for corrosion prevention. This is used typically with lead-free alloys like SAC305 or SnBiAg.

Benefits: Water can remove it easily; provides a spotless board surface that high-reliability products require; good wetting properties on challenging surfaces.

Challenges: Requires a cleaning step, which is added cost and time to production; the residues must be wiped off the surface at once to avoid corrosion.

Best Use Cases: Best suited for aerospace and medical PCBs where cleanliness is a requirement. For example, water-soluble flux is best used on a high-density medical device PCB where signal integrity is of paramount importance.

Rosin Solder Paste: A Versatile Classic

Rosin solder paste contains a flux based on natural or synthetic rosin and provides good wetting on the majority of surfaces. It has a residue, which can be cleaned if necessary. Leaded and lead-free forms are available, and rosin paste is flexible with many applications.

Advantages: Suitable for application on a range of components and boards; non-corrosive residues; good shelf life and handling ease.

Challenges: Can be tacky and pull in dust if not wiped clean; less aggressive on highly oxidized surfaces.

Best Use Cases: Best used for prototyping and low-volume manufacturing. Rosin paste provides consistency in test stages without the necessity to clean in the first instance.

Understanding Solder Paste Alloy Composition

The composition of the solder paste alloy has a very significant impact on performance. Some common alloys are:

SAC305 (Sn96.5/Ag3.0/Cu0.5): Typical lead-free alloy with high thermal fatigue resistance, perfect for harsh applications.

SnBiAg (Tin-Bismuth-Silver): Low-temperature, lead-free alloy, best for sensitive components.

Sn63/Pb37 (Tin-Lead): Traditional alloy, proven but largely replaced by RoHS restrictions.

Choosing the Right Solder Paste for Your Application

The choice of the right solder paste depends on a variety of factors:

Compliance with Regulations: Choose lead-free solder paste like SAC305 for use in RoHS-compliant markets.

Application Environment: Apply water-soluble paste for high-reliability applications first, and apply no-clean paste for consumer products.

Component Sensitivity: Use low-temperature alloys like SnBiAg for components that are heat-sensitive.

Production Volume: No-clean paste is more preferred where high-volume production takes place, while prototyping favors rosin paste due to convenience.

Solder paste choice is a fine tension between compliance, performance, and productivity. At PCBX, we are concerned with the expertise of solder paste alloy chemistry and flux type to meet specific project requirements. Whether lead-free, no-clean, water-soluble, or rosin paste, synchronizing your choice ensures reliable, high-quality solder joints time in and time out. By thorough testing, you guarantee successful PCB assembly, justifying the reliability of your electronic products.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Cold solder joints result from improper soldering, impacting PCB performance. Detection and prevention via proper technique and equipment ensure reliability.

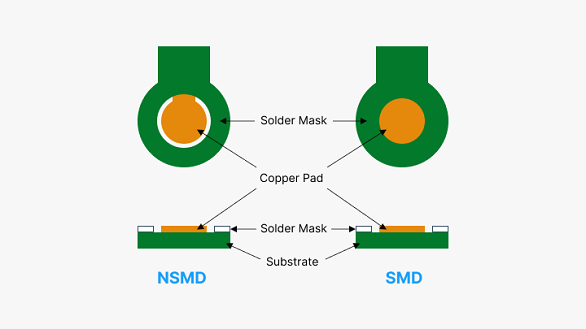

Solder masks protect PCBs, while paste masks aid precise component placement during assembly, both crucial for PCB reliability and efficiency in electronics.

Solder masks protect PCBs from environmental damage and electrical shorts, enhancing reliability and aesthetics. The application is complex, requiring professional fabrication to ensure quality and compliance with regulations.