Mastering the Choice of Solder Wire for Your Electronics Projects

Selecting the right solder wire, with consideration for composition, flux type, and diameter, is crucial for creating reliable electronic connections in both hobbyist and professional settings.

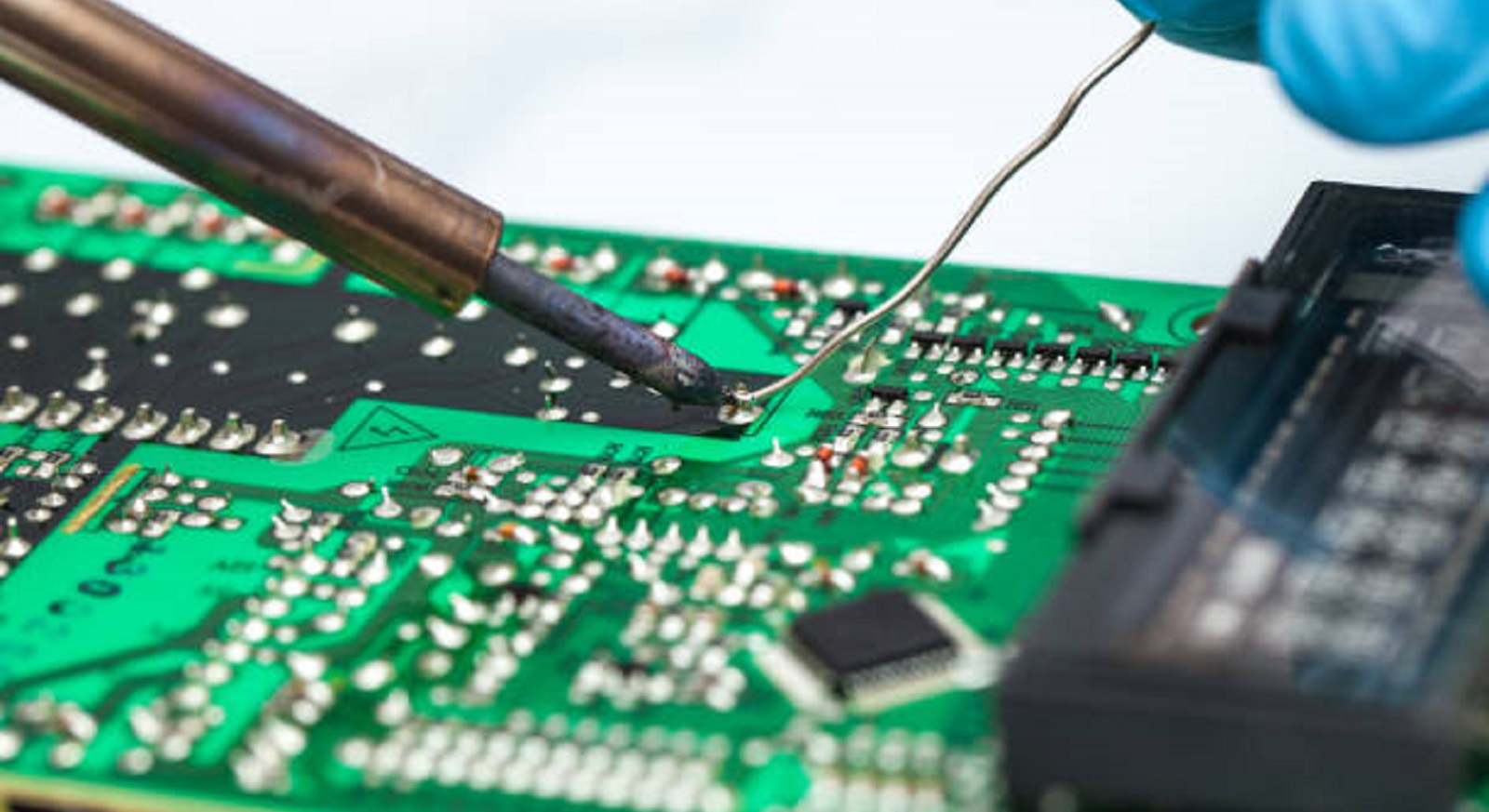

In the world of electronics, soldering is the basic knowledge that is essential in building lasting connections. The word 'solder' is of Middle English origin, 'soudur,' which means the combination of 'solidare,' or to make solid. The solder wire is the binding element in an electronic circuit, as it connects the components to provide all-rounded functionality. Choosing the best solder wire is crucial in the success of the connection. Whether it is in the world of hobby electronics or in an industrial setting, the knowledge of selecting the correct solder wire is paramount to the success of any project.

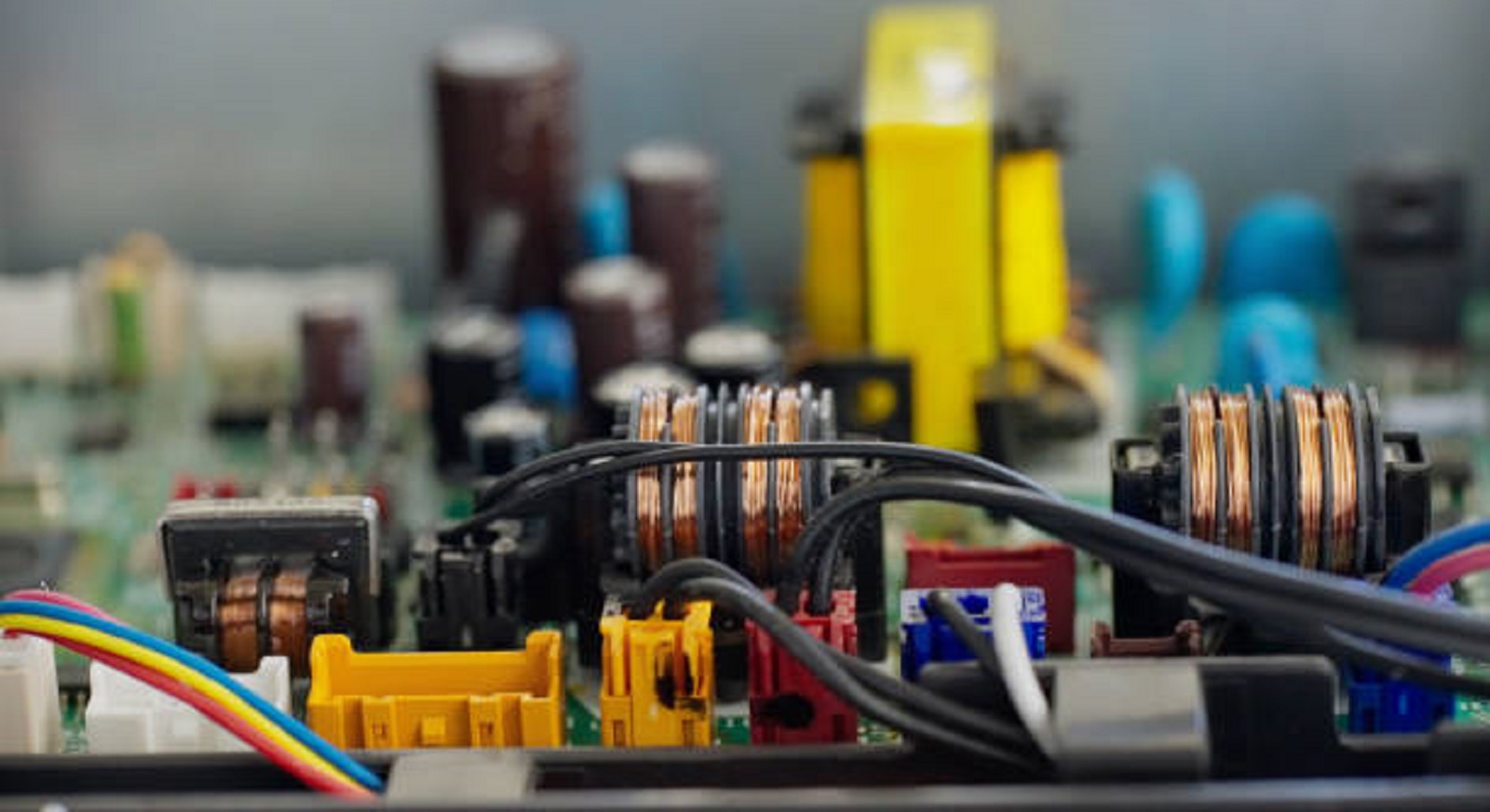

Basics of Solder Wire

Solder wire is a fusible metal alloy that joins electronic components flawlessly by melting and creating a conductive link. Conventionally, it consists of a lead and tin combination. But due to the arrival of health and environmental issues, lead-free variants are now chosen as a preferred alternative. The efficient use of solder wire can be the difference between a functional product and a problematic device.

Factors of Selecting Solder Wire

Composition of Alloys: Leaded vs. Lead-Free

Leaded Solder: Leaded solder has always been the most popular solder used in soldering. This solder is a combination of tin and lead, and it comes in different mixes, such as 60/40 or 63/37. The leaded solder also has a lower melting point, ranging from 183°C to 190°C, and a sharp solid-liquid interface, making soldering easy. However, the health and environmental implications of lead are some of the disadvantages of using leaded solder, and that’s why people have shifted to using other solders despite their benefits.

Lead-Free Solder: Made to meet the health requirements of modern regulations like the Safe Water Drinking Act, typically consisting of a mix of tin, silver, and copper materials. These solders require a certain high temperature for melting (217°C to 227°C) and can be a bit difficult for beginners but are being widely accepted for their compatibility with health regulations.

Types of Flux Cores

The flux is very important in soldering because it cleans the metal surfaces and makes the place ready for good adhesion of the solder and high joint quality.

Rosin Core Flux: This is particularly suitable for electronic applications because it assists in forming good bonds with a minimum of corrosion and often leaves sufficiently small amounts of residue that cleaning after soldering is not usually necessary. Being naturally derived, this would make it a decent choice for most soldering jobs.

No-Clean Flux: The name itself suggests the minimum amount of residue. These can be left on the joint without post-cleaning; this is usually ideal when dealing with electronic components that are sensitive to chemical residues.

Water-Soluble Flux: While providing effective cleaning action, with resultant strength in the joints, water-soluble flux requires a rigorous cleaning process after soldering to eliminate the residual residues, which may lead to corrosion after some time.

Diameter of Solder Wire

The diameter of the item is of prime importance in order to get the required precision.

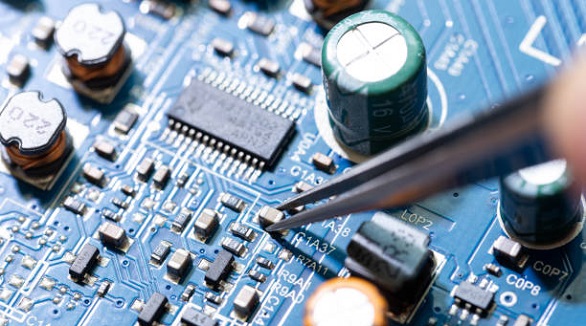

Thin (0.4mm-0.8mm): These are suitable for detailed applications such as surface mount technology (SMT), where high precision work has to be done.

Medium (0.8mm to 1.2mm): The medium size of the solder provides a good medium that can be used in a variety of soldering tasks.

Thick (1.2mm & above): This is suited for joint connections and is preferred for power electronics where higher mechanical strength is demanded.

Specialized Solder Alloys for Diverse Needs

Tin-Antimony Solder: This lead-free alloy of 95% tin and 5% antimony is perfect for the most durable and strong applications due to its high resistance to sudden extreme temperature changes, hence suitable for plumbing and some electronic applications.

Copper-Tin Solder: This solder consists of 97% tin and 3% copper and hence finds favor in plumbing. The strength it offers is required in a high-stress environment. Thus, it makes sustainable joints without lead.

Silver-Bearing Solder: Recognized for its content of silver, this solder is ideal for low-lead brass and high-reliability electronic applications. This is because of its strength and flexibility over a great melting range of 420°F to 460°F.

Application-Specific Recommendations

Electronics Repair and Prototyping: Use lead-based (60/40) or lead-free SnAgCu with rosin or No-clean flux, and a diameter ranging from 0.6mm to 1.0mm.

Surface Mount Technology (SMT): Lead-free process with silvering for enhanced wetting properties, using no-clean flux; 0.4mm to 0.6mm diameter for precise applications.

Stepper Motor/Heavy Duty Wire Leads: Lead-free and copper-rich for maximum strength, utilizing rosin core flux and having a diameter of 1.0mm-1.5mm.

DIY and Hobbying Projects: If allowed, lead-based solder is great for beginners, combined with rosins or water-soluble flux, and with a diameter of 0.8mm.

Attaining success with soldering starts with having the appropriate solder wire. Although lead solder is widely available and recognized for use within certain regulated sectors, it is recommended to consider the various lead-free solder options available, which conform with today’s demands of improving both quality and environmental conditions. Details such as solder flux and solder diameter offer specialized soldering that specifically meets project requirements by ensuring reliable and lasting connections are created. However, with complete knowledge of solder composition, solder flux, and solder diameter, and by assessing the unique demands of your project, the soldering process performed will only become more reliable and efficient with time.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Lead-free solder, safer for the environment, requires higher temps and careful handling; lead solder offers ease but poses health and environmental risks.

Master soldering chip components on PCBs using proper tools and techniques, ensuring precision and reliability for both hobbyists and professionals in electronics.

Solder masks protect PCBs, while paste masks aid precise component placement during assembly, both crucial for PCB reliability and efficiency in electronics.