Differences between Advanced and Standard PCBs

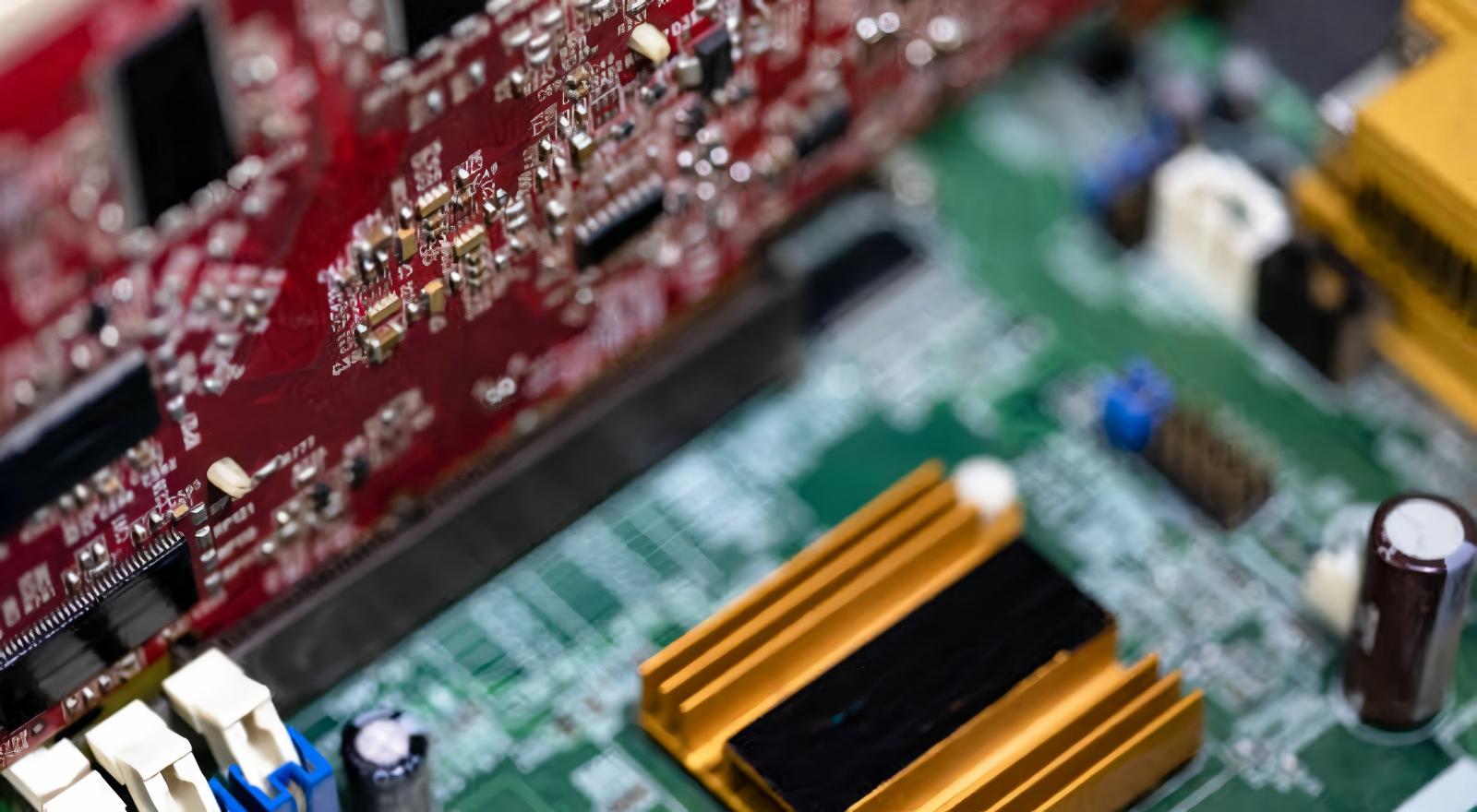

PCBs form the foundation of electronics; standard PCBs offer cost-effective simplicity, while advanced PCBs cater to high-performance and precision requirements.

In the dynamic environment of the electronics industry, Printed Circuit Boards (PCBs) are at the core and form the foundation on which electronic devices are built. To meet the demands for more complex and efficient electronic devices, PCBs have branched out into two main categories: Standard PCBs and Advanced PCBs. The knowledge of the differences between these two can greatly affect the outcome of a project. This article will discuss the historical context, design intricacies, material usage, manufacturing processes, performance characteristics, and applications of standard and advanced PCBs.

Historical Context and Evolution of PCBs

The use of PCBs dates back to the 1960s and gained popularity as they formed a reliable foundation for providing a platform for electrical connections and supporting electronic components. The electronics industry has witnessed a revolutionary change since 1990, when IBM introduced its SLC technology, allowing for the development of microvia technology. This change has been instrumental in the development of high-density interconnections (HDI), allowing advanced PCBs to accommodate the compact and sophisticated electronic devices of today, such as smartphones and military technology.

Design Complexity

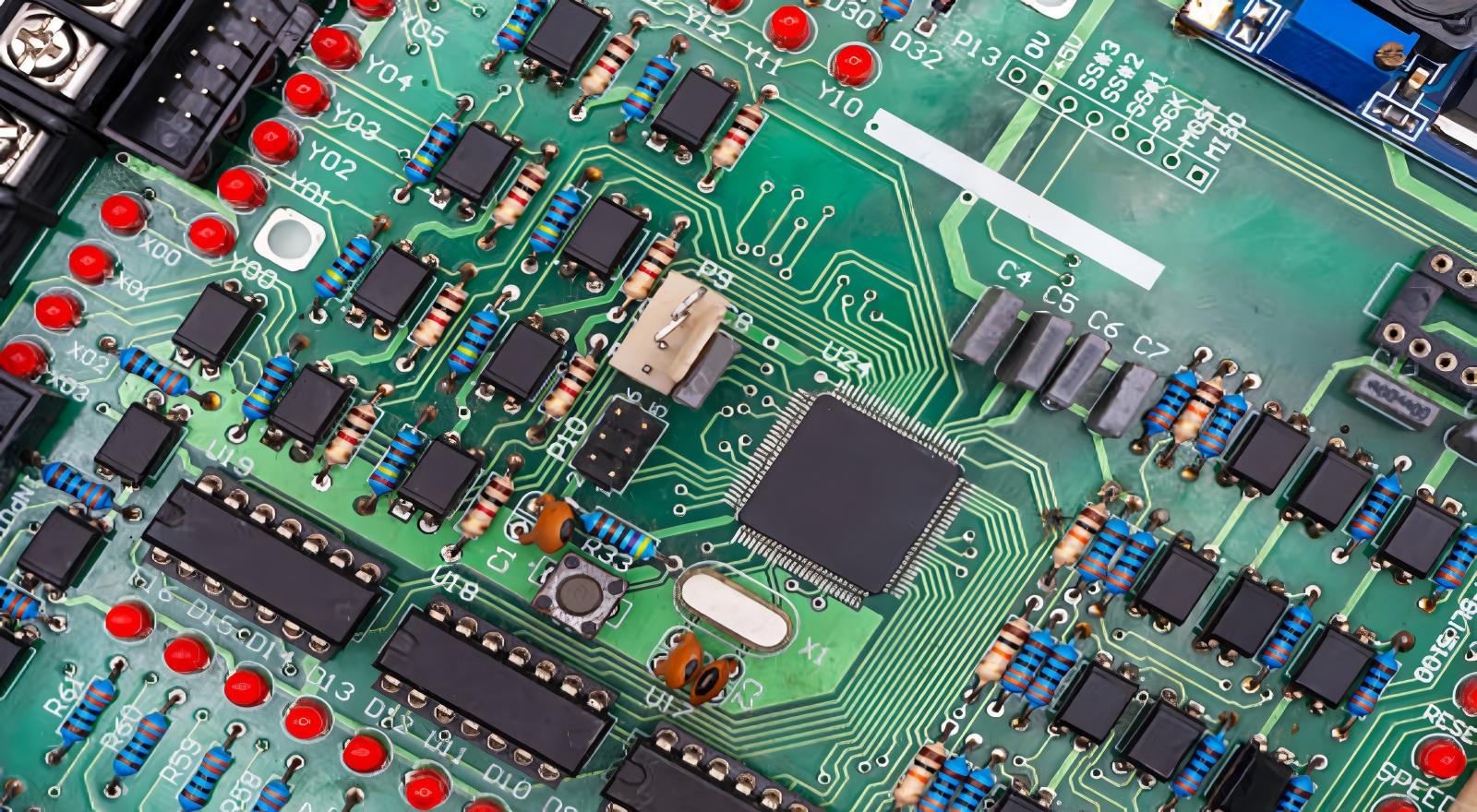

Standard PCBs: Standard PCBs are the epitome of simplicity and traditional design. Standard PCBs usually vary from single-layer to four-layer designs, which are sufficient to support general electronic functionality without requiring complex routing. They are most suitable for consumer electronics in the mass market, where cost-effectiveness is a concern. The design is uncomplicated, which enables faster production with less complexity.

Advanced PCBs: On the other hand, advanced PCBs contain the intricacies of the design required for high-performance applications. In this context, the presence of micro-vias, blind vias, buried vias, and high-density interconnects are common. The presence of such design intricacies makes advanced PCBs capable of handling complex circuit designs. The complexity of the circuit designs makes it mandatory to use advanced Electronic Design Automation (EDA) tools for precise functionality, making advanced PCBs suitable for high-tech applications.

Material Choice and Layering

Standard PCBs:Usually made of standard materials like FR-4, a combination of woven fiberglass cloth and epoxy resin. This material offers a good trade-off between robustness and economy, and it is adequate for designs that require moderate thermal and electrical performance.

Advanced PCBs: Employ advanced materials like Rogers laminates or polytetrafluoroethylene (PTFE), which have better electrical performance like low dielectric constants and low signal attenuation. These materials are critical for realizing multilayered designs, which may involve more than eight layers, to support complex features and higher circuit density for high-speed designs.

Manufacturing Processes

Standard PCBs: Standard PCBs make use of conventional manufacturing processes that highlight the cost-effectiveness of the process and the speed of production. This includes basic processes such as drilling, etching, and laminating, which can be used for boards that do not require precision.

Advanced PCBs: Advanced PCBs require advanced manufacturing processes such as laser structuring, sequential laminating, and precision plating, which can accommodate smaller line spacing and multiple layers. ENIG is usually employed for surface treatment, ensuring the durability of the board while maintaining signal integrity. Even though the process is more complex, the end result is a board that can accommodate advanced functionality.

Performance Characteristics

Standard PCBs: These offer satisfactory performance for devices that require moderate levels of signal integrity, thermal management, and power supply. Standard PCBs can be used for applications that require moderate levels of performance, where simplicity is emphasized rather than speed or frequency.

Advanced PCBs: These are designed for use in environments that require high levels of signal integrity, thermal management, and power supply. Advanced PCBs allow for better management of impedance, ensuring that signal loss is minimal for greater stability and reliability.

Application Fields

Standard PCB: It is mainly used in the fields of consumer electronics and industrial applications. It is best for the production of home appliances, standard lighting systems, computing devices, etc. It is best for applications in which simplicity, cost-effectiveness, and standard performance are the key requirements.

Advanced PCB: It is mainly used in fields such as aerospace, telecommunication, automobiles, etc. It is best for the production of computing devices in which high-performance requirements, precision, etc., are the key requirements.

Choosing a standard PCB or an advanced PCB entirely depends upon the requirements of the particular project that needs to be accomplished. Standard PCBs are best for projects that require cost and simplicity, while advanced PCBs are required for projects that require performance, precision, and sophistication. It is important to understand the difference between standard and advanced PCBs in order to make a proper decision that can fulfill the technical requirements of a device.

At PCBX, we are offering standard and advanced PCB services, and our facilities are designed to cater to a variety of industries and requirements. Our facilities are equipped with the latest technology, which ensures that the PCBs delivered are of the highest standard, enabling your devices with performance excellence and reliability.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCBs are essential for electronic devices, providing mechanical support and electrical connections. This article explores the importance of PCB panel dimensions, standard sizes, and optimization techniques. Key points include cost-efficiency, ease of manufacturing, quality control, and optimal layouts. Factors like board size, volume needs, and equipment capabilities influence panel size. Coordination with manufacturers, using design software, and employing standard sizes can enhance production efficiency and quality.

PCBs are vital components in most electronic devices, including consumer electronics, medical devices, and automotive systems. PCBX offers diverse, high-quality PCBs, driving modern technology with innovation and reliability.

Most electronic circuits are mounted on PCBs, or Printed Circuit Boards, which provide mechanical support and electrical interconnection of electronic components. There are, however, special applications that involve the use of single and double-sided PCBs, multi-layer PCBs, or even rigid and flexible PCBs with aluminum backing, targeting medical, industrial, auto, and aerospace industries. They may use materials such as fiberglass, epoxy, aluminum, and others.