How to Calculate PCB Aspect Ratio

PCB aspect ratio, relating board thickness to via diameter, is key for quality, cost, and reliability in manufacturing, impacting plating and design.

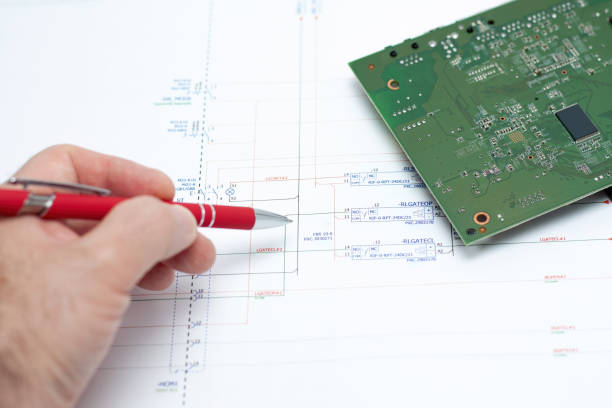

The aspect ratio in the fabrication of PCBs is a critical parameter that directly determines the quality, reliability, and cost-effectiveness of the final product. The following article gives an in-depth overview of what the PCB aspect ratio is, its importance in production, and the steps to correctly calculate it, ensuring that your designs are both efficient and manufacturable.

In PCB vocabulary, aspect ratio is defined as the relationship between the general thickness of the board and the diameter of the tiniest drilled hole-usually called a via. In electroplating, copper plates onto the walls of such via holes, thereby creating the electrical path between layers.

Mathematical Formula:

\[ \text{Aspect Ratio} = \frac{\text{Board Thickness}}{\text{Via Hole Diameter}} \]

For example, if a PCB is 0.062 inches thick and the diameter of a thru-hole is 0.020 inches, then the aspect ratio will be 3:1. It is very important to keep this ratio within certain limits to maintain the quality and reliability of manufacturing.

Why PCB Aspect Ratio Matters

Plating Quality: A lower aspect ratio increases uniformity in via plating. This is a must to ensure that there is reliable electrical pathing between the layers. Higher aspect ratios lead to non-uniform plating, which may cause functional failures.

Manufacturability: High aspect ratios can introduce several problems. For one, they can complicate drilling, which then limits how effectively plating is performed. One consequence of a high-aspect-ratio via could be an inability to fully deposit copper within the via, which may lead to failures.

Cost Efficiency: A low aspect ratio keeps the manufacturing cost down by simplifying the plating process and minimizing the chance of defects that would require costly rework.

Reliability: A well-optimized aspect ratio contributes a great deal to the structural and functional integrity of the PCB. It ensures that boards can resist operational stresses during their lifetime without degrading prematurely.

The general rule of thumb in most cases concerning aspect ratios for thru-holes is not to exceed 10:1. For example, if a board is 0.062 inches thick, via diameters should not be smaller than 0.006 inches to reliably maintain quality in production.

How to Calculate PCB Aspect Ratio

Step 1: Measure Board Thickness

The first thing to do is to determine the overall thickness of the PCB, which involves all layers placed together from copper to dielectric and anything else.

Step 2: Determine Via Hole Diameter

After that, carefully measure the diameter of the smallest via hole on the board. It should be an inner diameter after any kind of plating has been applied.

Step 3: Apply the Aspect Ratio Formula

With the help of the formula:

It is defined as the ratio between the thickness of the board and the diameter of the via hole. That is,

Aspect Ratio = Board ThicknessVia Hole Diameter

Example: For a board with thickness of 1.6 mm and the smallest via hole diameter of 0.2 mm, the aspect ratio would be:

\[ \text{Aspect Ratio} = \frac{1.6 \, \text{mm}}{0.2 \, \text{mm}} = 8:1 \]

The aspect ratio is within the range that can be managed by most of the manufacturing processes.

Special Considerations for Microvias

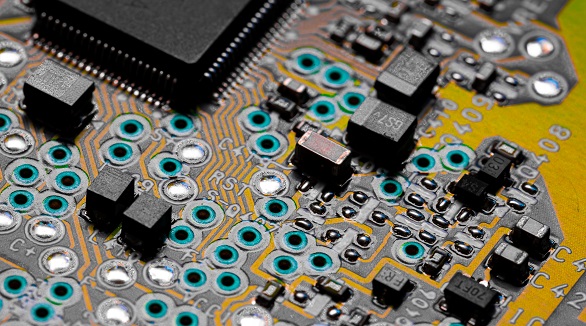

Microvias are small vias in multi-layer boards, usually applied for dense boards; the standard is different because their application varies:

Size Definitions: Microvias conventionally are defined as having an aspect ratio of 1:1 with a maximum finished hole diameter less than or equal to 0.010 inches according to IPC standards.

Manufacturing Challenges: The minute size of microvias makes them a bit difficult to fabricate, but they provide much greater density and flexibility in design to meet the growing demands of complex PCB space constraints.

Design Advantages: Even though these are complex structures, microvias reduce electromagnetic interference and allow for better routing options with compact designs.

Industry Standards and Best Practices

A aspect ratio above 6:1 is usually considered large; as such, manufacturing tries to keep it around that number, or smaller, to ease manufacturing and ensure high reliability. By the same token, this lessens the stresses imposed upon a via during soldering and thermal cycling, making the more reliable PCB.

Engage the Manufacturers: Consulting the PCB manufacturers during the early stages of the design is important in understanding their capability with regard to aspect ratios. Some can accept higher, sometimes as high as 12:1, but at a more complex and costly deal.

Optimize Design Layout: It is a matter of balancing between board thickness and hole diameter. A little tweak in your PCB design will help to improve the manufacturability without necessarily compromising the performance.

Practical Ways to Handle Aspect Ratio

Early Design Considerations: Design the product by keeping aspect ratio guidelines in mind to avoid redesign or manufacturability problems later in the product development cycle.

Prototyping: During the prototyping process, test different aspect ratio limits to create the most functional and robust design parameters.

Design Buffers: Design buffers are set for handling deviations that may be encountered by a manufacturing process to allow your design flexibility in terms of adaptability to changes.

The calculation and management of the aspect ratio of a PCB are not only technical but also a strategic part of the design and manufacturing process. The well-determined aspect ratio leads to fewer challenges in its manufacturing and encourages the designer to create reliable and high-performing PCBs. A PCB designer will be able to ensure that their products meet accepted industry standards for functionality at real-world applications by remaining within recommended limits on aspect ratios. Understanding and applying the principles of aspect ratio calculations can greatly affect the efficiency and success of electronic products in many different fields.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

CTI measures PCB material's resistance to electrical tracking, ensuring safety and reliability in electronic circuits, crucial for design and manufacturing.

Non-plated through holes provide mechanical support in PCBs but pose stress and precision challenges, requiring careful design, materials, and manufacturing.

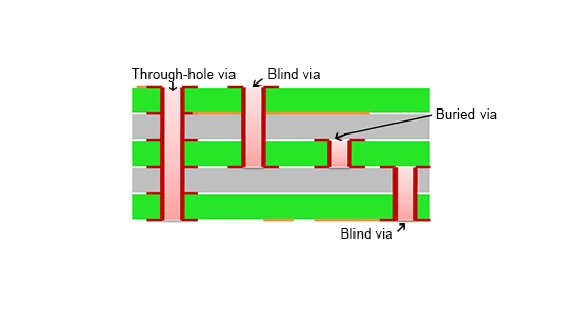

A printed circuit board includes a number of copper foil circuits, which are interlinked by vias. Via (through-hole, blind, buried, stacked, microvias) provides critical interlayer connections in high-density interconnection boards. Blind and buried vias increase the density of boards without adding size; hence, they are imperative for modern trends of miniaturization and high-speed signal transmission. These vias are plated with conductive materials, usually copper, so the electron flow can happen without much effort. Although advanced via types, like stacked vias, cost more, they save up much space and significantly improve routing capacity.