PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Panel-plating blind-hole filling enhances PCB reliability and efficiency by integrating filling and plating, meeting the demands of compact, complex, and trustworthy devices.

PCB panelization improves productivity, reduces costs, and facilitates automation by assembling several smaller PCBs into one large panel, ensuring uniformity.

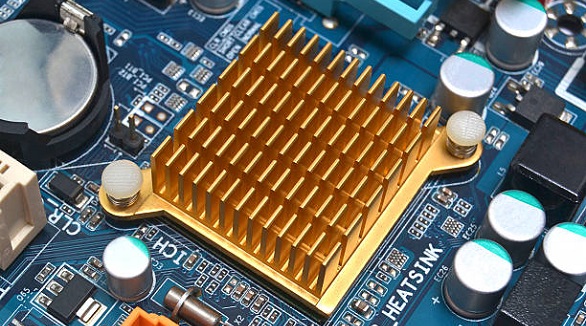

Heat sinks are essential for reliable PCB design, managing heat in high-density components like transistors and LEDs, ensuring optimal performance.

Preheating PCBs enhances soldering by reducing thermal shock, improving wetting, and activating flux, using methods like conduction, convection, and IR.

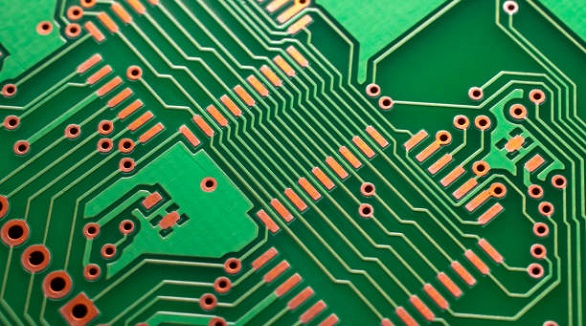

Controlled impedance is crucial in modern PCBs, ensuring signal integrity through precise trace and material design, essential for high-speed applications.

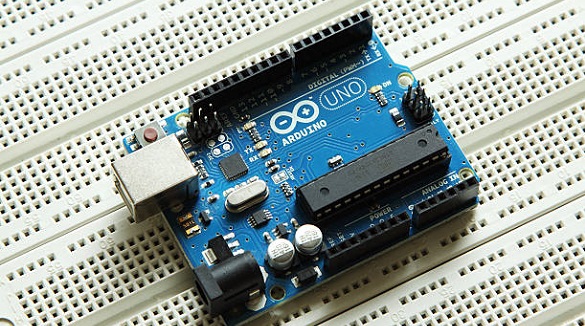

FPGAs with Arduino, like MKR Vidor 4000, enhance electronics prototyping with high flexibility, real-time processing, and customization for diverse applications.

PCB aspect ratio, relating board thickness to via diameter, is key for quality, cost, and reliability in manufacturing, impacting plating and design.

Electronic module assembly is crucial for innovation, driven by demands for high-performance, reliable modules in fields like connectivity and electric transportation.