Optimal Dielectric Material Selection for Aluminum PCBs

Choosing the right dielectric material for aluminum PCBs ensures effective thermal management, insulation, and reliability in high-power applications like LED lighting and vehicles.

In high-power electronic applications, it has been recognized that aluminum PCBs are a capable solution due to their superior thermal dissipation capability. Above characteristics find their most critical applications in LED lighting, vehicles, and power converter circuits. In aluminum printed circuit boards, however, the importance of selecting the right dielectric materials becomes relevant-a choice that sets up not only the thermal dissipation of power but also acts as an insulation and reliability factor. This primer will explore the intricacies of selecting competent dielectric materials for aluminum printed circuit boards.

Dielectric Materials in Aluminum PCB

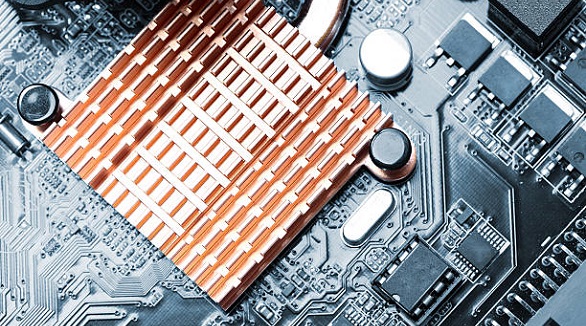

A crucial aspect of an aluminum PCB is the presence of the base made of the same metal—aluminum—that acts as a heat sink. The base forms a permanent component of the printed circuit board. However, the importance of the dielectric layer cannot be ignored. The layer lies between the base material made of aluminum and the copper circuit. It ensures no electrical conductance between the copper tracks and the base material. On the other hand, it efficiently dissipates heat from the component.

Important Factors in Dielectric Material Selection

Thermal Conductivity: The Foundation of Heat Transfer Solutions

Aluminium PCBs are known for their superior thermal management capabilities. These are required for preventing overheating during the operation of power-consuming systems. The dielectric needs to have strong thermal conductivity to effectively dissipate the heat from the copper layers to the aluminium core. Typical dielectric materials have thermal conductivities between 0.8 to 1.5 W/mK. However, high-quality materials having conductivities of 2.0-3.0 W/mK are more desirable for high-power applications such as LED lights or motor drivers. Such materials are capable of maintaining their performance at higher temperatures.

Dielectric Constant (Dk) for Signal Integrity

Dielectric constant (Dk) refers to the measure of a given material’s capability of storing electric field energy. When designing components that deal with signals and require high-speed operations, such as RF and microwave components, it is desirable to consider low Dk. Generally, a Dk value lies between 3.5 and 4.5. But selection of materials with lower values around 2.5 will improve design efficiency as it prevents signal delays and crosstalk, which is very important for successful data and signal integrity.

A low dielectric constant with other essential properties like thermal conductivity may sometimes be difficult to achieve. In many cases, there is a need for careful consideration of the main requirements of the particular project, to decide either the thermal or electrical properties that come first.

Dielectric Thickness: The Balancing Act

The thickness of the dielectric directly influences both thermal and electrical performance. While a thinner dielectric decreases thermal resistance, improving heat dissipation, it also risks increasing electrical breakdown under high voltages. Thick dielectrics are better electrically insulating but worse thermally. For most applications, an optimal balance between 75-100 μm allows adequate heat transfer without compromising electrical insulation to ensure the board meets both thermal and electrical demands efficiently.

Breakdown Voltage and Insulation Strength

The dielectric material should not break down at the maximum operating voltage of the application. Breakdown voltage is one of the most critical parameters, particularly in high-voltage systems like power supplies. For a dielectric material with a high enough breakdown voltage-usually measured in volts per mil-safety and performance are ensured due to better resistance to electrical surges without failure in insulation. It is important to ensure that the breakdown voltage of the material is above the limit that the system may reach under operation by an adequate safety factor for reliable service.

Environmental and Chemical Stability

Aluminum PCBs tend to find applications in conditions involving moisture, chemicals, or varying temperature levels. This means that the chosen dielectric material should be resistant to these conditions in order to ensure durability. The most preferred materials have low moisture absorbability and high chemical resistance. Furthermore, materials that support large temperature ranges, for example, from -40°C to 150°C, tend to increase durability. Such temperature ranges increase functionality.

Common Dielectric Material Types

Epoxy-Based Dielectrics: They are quite economical. They have reasonably good thermal conductivity along with electrical insulation. However, they may not be appropriate for high frequency or high-temperature areas because of their moderate Dk of 4.0.

Ceramic-Filled Dielectrics: They possess a higher value of thermal conductivity (2.0-3.0 W/mK) due to which they are preferred for use in applications requiring a higher power capacity. Although they possess improved heat dissipation properties and are more stable, their dielectric constant value might be marginally higher.

Polyimide Dielectrics: Polyimides are known for their flexibility and high temperature resistance. Polyimides can be used for applications that demand strength during high temperature exposure. Despite having low thermal conductivity, they can be used when high strength is necessary.

Dielectric Optimization

Apart from the selection of the right material for the dielectric, other methods involved the following:

Align Dielectric Properties with Application Requirements: It should be clearly specified in a project whether a focus on thermal conductivity, Dk, or insulation strength is required. This would be followed according to the application requirements, like emphasis on high thermal conductivity in the case of LEDs or low Dk in RF circuits.

Simulate the Thermal & Electrical Performance: The simulation tools available should be used to understand the thermal performance of different materials. This will help reduce the costs associated with new production by allowing the materials to be fine-tuned.

Explore Multilayer Design Concepts: The use of multiple layers of different dielectrics in complex designs can help manage the thermal as well as the electrical aspects.

Selecting the right dielectric material for aluminum-based printed circuit boards is always a task requiring a protracted consideration of the associated thermal, electrical, and environmental factors based on the strict requirements for contemporary electronic designs. By considering significant parameters such as the thermal conductivity coefficient, dielectric constant values, breakdown voltage strength, and stability in the environment, you will be able to improve the functionality and functionality of your board. By cooperating with PCBX, you can increase the chances of making the right judgment on the selection of the material for your designs and achieve the best results in the field with your projects on the lighting aspects of LEDs or improvement in automotive electronics.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Aluminum PCBs offer cost-effective thermal management for moderate applications, while copper PCBs excel in high-performance electrical and thermal tasks.

Select aluminum PCBs for excellent heat management or FR4 PCBs for cost-effective versatility in diverse electronic applications.

Aluminum PCBs are widely used electronic boards with comparatively better heat dissipation properties. The aluminum core cools down the components of the product, thereby improving its performance. These are eco-friendly, light, and strong PCBs and hence appropriate to be used in audio equipment, power supplies, and lighting products such as LED lighting.