Panel Requirements for PCB Assembly

PCB panelization improves productivity, reduces costs, and facilitates automation by assembling several smaller PCBs into one large panel, ensuring uniformity.

The uniformity of a printed circuit board is very important in ensuring that electronic equipment functions well. All PCBs, whether small or large in size, have to be manufactured in a similar manner, with some variations to keep the dimensions intact. These processes can often be very time-consuming and prone to potential errors. So, panelization is an important process in the manufacturing of printed circuit boards, which helps in attaining uniformity and minimizing these potential problems. The panelization of several PCBs into one larger panel helps the assembly services ensure quality and consistency in the production process.

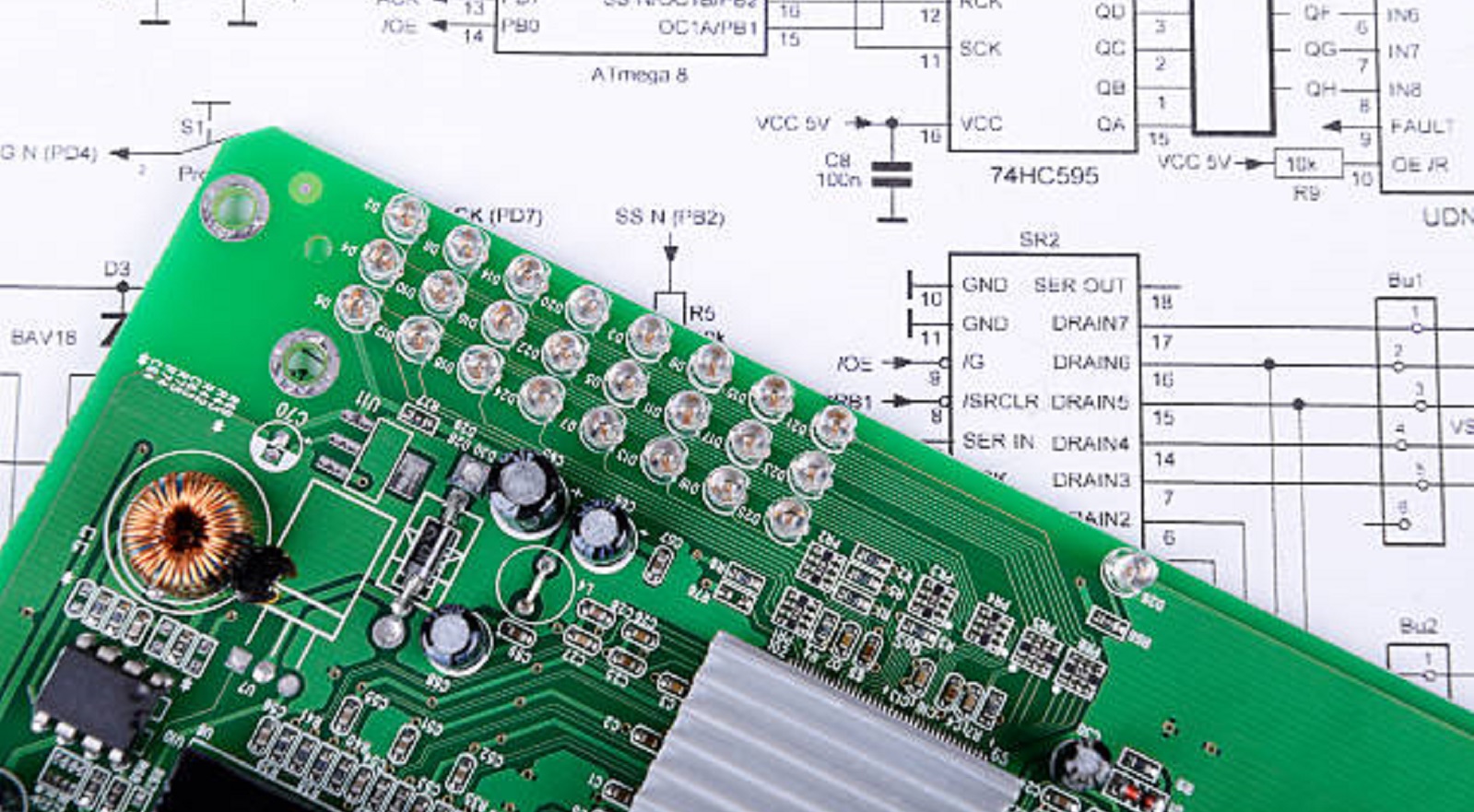

Panelization of a Printed Circuit Board

Panelization refers to the process of compiling several smaller PCBs onto a larger panel before going into assembly. The multiple benefits of this approach include:

Improved Productivity: Panelization allows the simultaneous processing of a number of circuit boards, saving handling and manufacturing time.

Cost-Effectiveness: Panelization minimizes waste and optimizes the use of materials, hence economizing the manufacturing process.

Reduced Handling: Fewer moves during assembly and therefore less damage or handling errors.

Facilitated Automation: Panelization allows smooth facilitation with automated processes such as a pick-and-place machine, reflow soldering, and automated optical inspection-all of these ensure productivity and consistency.

Key Considerations for Efficient PCB Panelization

Effective panelization in PCBs requires a number of important aspects, all of which help minimize errors and optimize the production workflow:

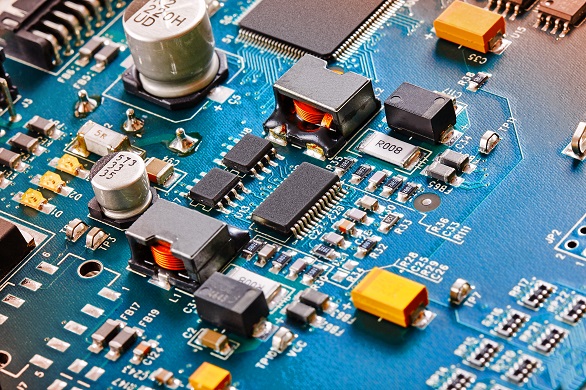

Panel Size and Material

Understanding panel size requirements is important for effective assembly and functionality. The panel design must be optimized with the use of available space, but at the same time, it has to be compatible with the capability of an assembly line. Also, the choice of appropriate material, such as FR-4 or aluminum, ensures that the final product will survive under its intended use and environmental conditions.

Panel Size: Size should be appropriate to the maximum working area of the assembly equipment, which includes reflow ovens and pick-and-place machines.

Material Selection: The material should be able to withstand the thermal and mechanical stresses of the various assembly processes.

Component Density and Layout

Enough clearance and space must be left between boards to avoid assembly errors or any short circuits. A well-structured layout allows for even spacing between parts, making it easier to assemble and inspect the product with reduced incidences of defects.

Board Spacing: Ensure enough spacing between boards to accommodate cutting methods, edge treatments, and components.

Component Orientation: The same orientation for all PCBs ensures uniformity in the assembly process, such as soldering.

V-Score or Tab Routing

There is the major importance of selecting the appropriate methodology to produce a separation for each board from a panel. V-scoring introduces V-shaped grooves for easy board detachment, while tab routing secures PCBs with small tabs until separation. Which technology to use depends on how the PCB is designed and on the de-panelization that is requested.

V-Scoring: Suitable for cost-effective separation but needs to be carefully planned on boards with edge components.

Tab Routing: Provides more flexibility in panel design; however, manufacturing may take more time.

Fiducial Marks

Fiducial marks will be necessary for perfect alignment during the assembly process. These reference points, which may come in circular or cross-shaped patterns, are recognized by a vision system in the assembly equipment to assure accurate placements and soldering of components.

Placement: Well-positioned fiducials reduce the chances of misalignments and defects.

Design Specifications: Liaise with manufacturers to determine fiducial requirements that are within the capability of the equipment.

Copper Balance

Even copper distribution in a panel will ensure consistent thermal performance for soldering. Poor copper balance will lead to hotspots during reflow, impacting the quality and reliability of solder joints.

Even Spacing: Especially on power components, copper traces must be evenly distributed to avoid thermal imbalances.

Panelization Method

Effective production requires choosing the right panelization method. Techniques, such as step-and-repeat, array-based, or mixed layouts, address different design complexities and production volumes.

Step-and-Repeat: Places the same PCBs next to each other, optimizing space.

Array-Based: Arranges multiple boards in a grid for single design production.

Mixed Layouts: Combines different designs within a single panel, offering flexibility for varied projects.

Handling and Assembly Automation

This can include design for loading and unloading from automatic assembly equipment to expedite production. Considerations can include fiducial placement, edge clearances, and orientation that enhance automated handling while minimizing manual errors in handling.

Automation Alignment: Design panels to work well with automation assembly systems by saving setting time and increasing efficiency.

The Benefits of Expert Panelization

Panelization in PCBs is a highly valuable and sought-after technology that simplifies the manufacturing and assembly of PCBs, with major advantages on yield, cost, and streamlining of processes. Quality and precision at PCBX mean your panelization needs meet the expected standards.

For efficient PCB panelization, it is vital to collaborate with a qualified PCB manufacturer and an assembly service. PCBX not only produces excellent-quality panelized PCBs but also offers customized assembly services for various applications. Please feel free to inquire or start your panelization process with us now.

Efficient panelization in PCBs forms the basis for quality, consistency, and cost-effectiveness in contemporary PCB production. By focusing on a few key considerations, such as those involving panel size, material selection, layout, separation methods, and integration with automation, manufacturers can better their processes and result in superior products. Contact PCBX today for more information about how our professional panelization services can take your PCB assembly to the next level. Our customized solutions ensure that the unique needs of your project will be met with precision and professionalism.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCB panelization consolidates multiple PCBs into a larger board, improving manufacturing efficiency and reducing waste. Techniques include V-scoring and tab-routing. Proper design enhances assembly, testing, and cost-effectiveness.

PCBX offers fast, high-quality turn-key PCB prototype assembly services, including fabrication, component sourcing, and testing, all at competitive prices, to accelerate product development.

The article is developed concerning the breakthrough of integrated circuits and the need for custom PCBs in some electronic products. It enumerates ten golden rules in conducting PCB layout design and manufacturing: grid selection, routing, power layers, component placement, panel duplication, component value combination, frequent DRC, flexible silkscreen use, decoupling capacitors, and pre-production parameter checks. These rules provide for the optimum design and manufacturing of a PCB.