PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Common PCB assembly defects, their root causes, and proven prevention methods are outlined to improve reliability, yield, and manufacturing efficiency.

Proper trace-to-pad clearance in PCB design ensures safety, signal integrity, manufacturability, and longevity, following standards like IPC 2221 for optimal performance.

PCB thickness is essential for device performance, impacting signal integrity, thermal efficiency, and durability, thus requiring careful selection for optimal outcomes.

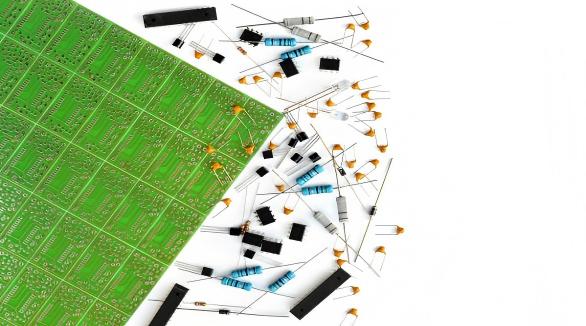

01005 components are key for miniaturization in electronics, requiring precise handling in PCB assembly to overcome challenges in soldering, placement, and inspection.

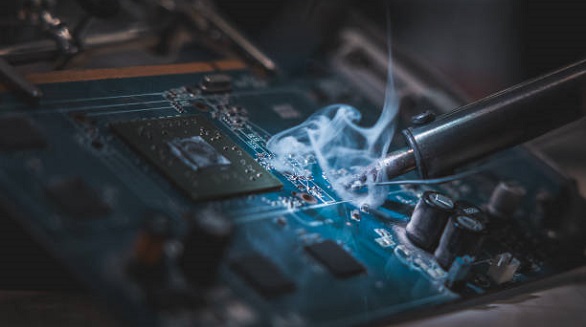

Selecting the right solder wire, with consideration for composition, flux type, and diameter, is crucial for creating reliable electronic connections in both hobbyist and professional settings.

Understanding resistor power ratings in PCB design is crucial for ensuring circuit reliability, thermal efficiency, and preventing overheating through strategic layout and derating.

PCB traces, vital for electrical connectivity, can suffer from stress, corrosion, or heat damage, and are repaired by careful inspection, cleaning, and soldering.

Choosing the right dielectric material for aluminum PCBs ensures effective thermal management, insulation, and reliability in high-power applications like LED lighting and vehicles.