SMT Contract Manufacturing in the Electronics Industry

SMT contract manufacturing boosts efficiency and lowers costs for electronics businesses, offering advanced technology access and allowing them to focus on essential operations.

In the sophisticated world of business nowadays, particularly in the electronics industry, the majority of businesses find themselves challenged to run extensive businesses with insufficient assets. Such a challenge is not unique to electronics; food processing and brewing are some of the industries that also contend with similar challenges. In order to survive such challenges and ensure market presence, businesses turn to contract manufacturing increasingly. In electronics, contract manufacturing using Surface Mount Technology (SMT) is now a key strategy that enables companies to maximize efficiency and creativity while maintaining costs at optimal levels.

Understanding SMT Contract Manufacturing

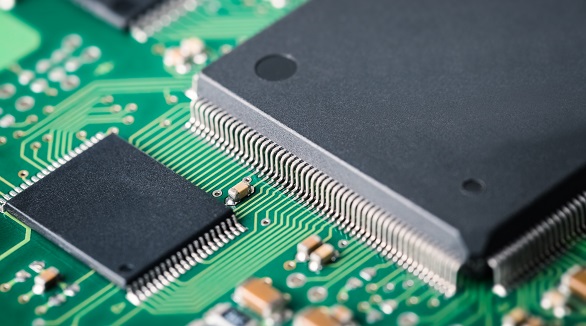

Surface Mount Technology is an innovative method in the electronics manufacturing sector, where electronic components are installed on the surface of printed circuit boards (PCBs). This differs from previous technologies, such as through-hole technology, where components are inserted through pre-made holes. SMT allows for the employment of smaller and denser components, leading to small yet high-powered devices.

Because SMT is complicated and requires investment, not all companies can perform such processes internally. That is where SMT contract manufacturing is beneficial. Contract manufacturers specialize in producing electronic components or complete products for other companies based on specified requirements. Such manufacturers add tremendous value in the sense that they utilize top-of-the-line technology and expertise to manage the production to allow their customers to focus on other business critical areas.

How SMT Contract Manufacturing Works

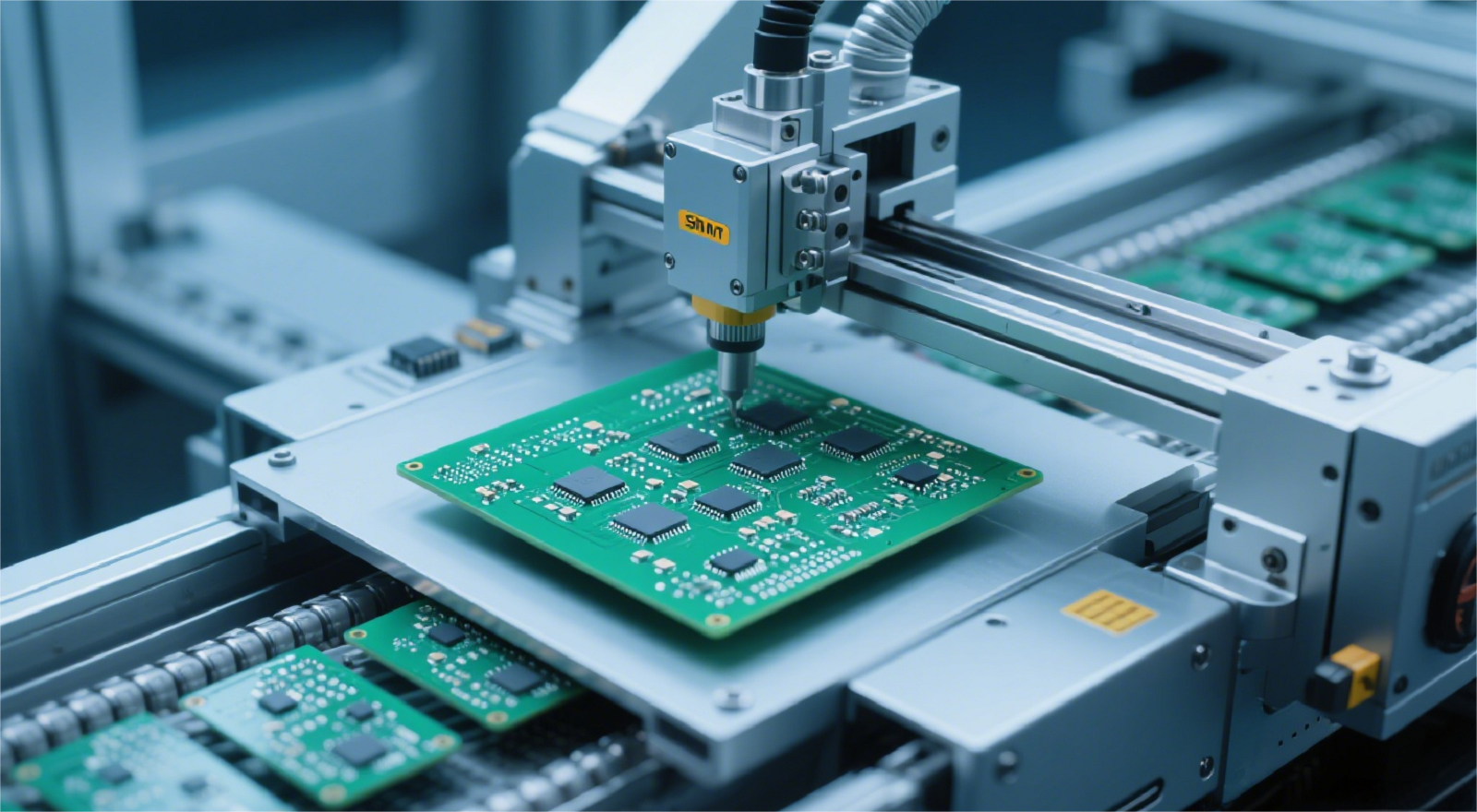

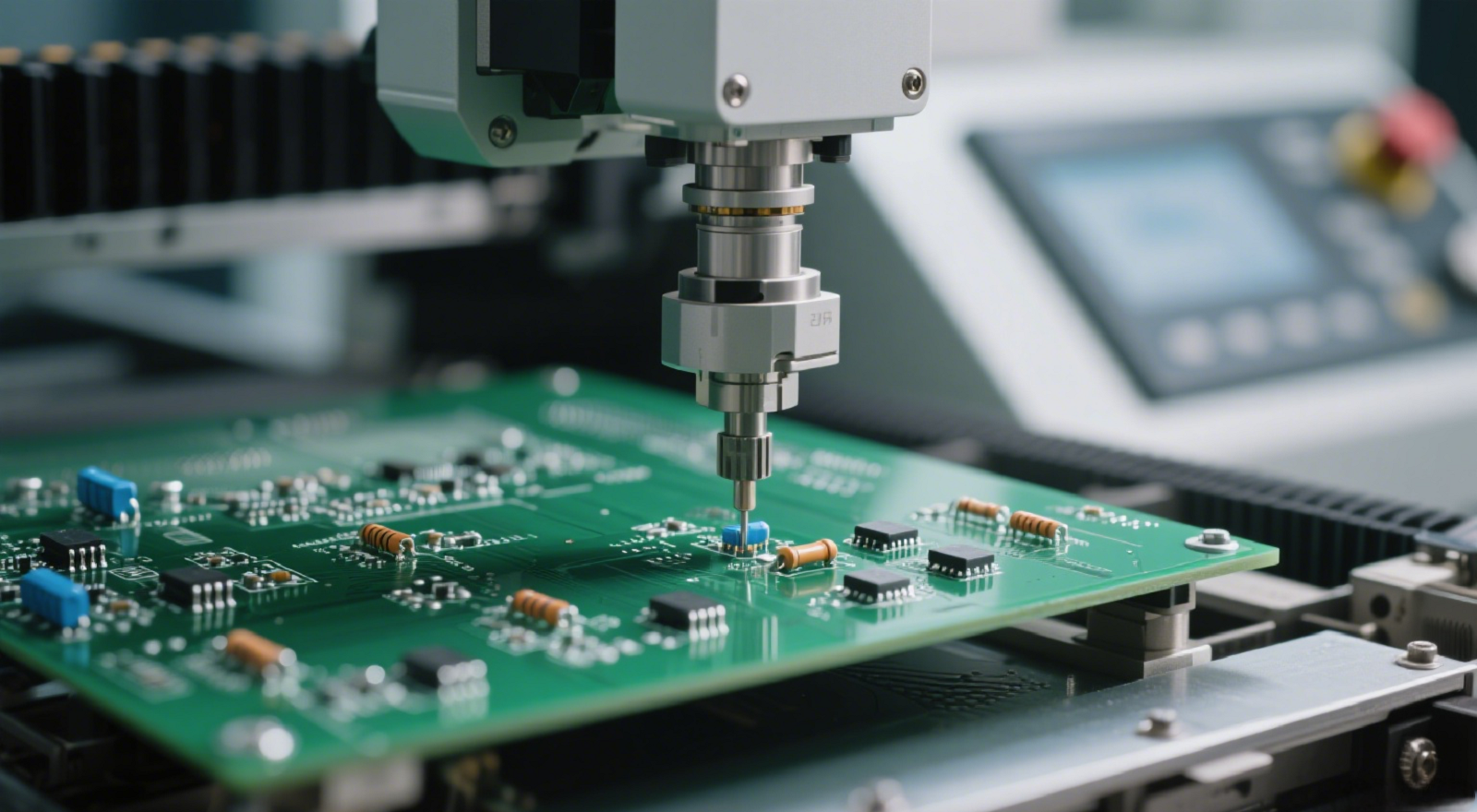

SMT contract manufacturing is started by the customer firm outlining specific requirements for the required components or systems. SMT contract manufacturers utilize their own sophisticated equipment and knowledge to produce these according to the outlined requirements. An extremely crucial aspect of the SMT process includes several steps that begin with the deposition of solder paste onto the PCB, followed by precise component placement. Once installed, the components are secured using soldering, typically completed in a reflow oven.

Quality control is a built-in aspect of SMT manufacturing. Inspection during the process includes strict checking, for instance, automated optical inspection (AOI), to detect defects and make the product stable. Prototyping is a significant process as well, allowing manufacturers to test and refine product designs before large-scale production, thus minimizing possible defects and shortening the cycle of manufacturing.

The Advantages of SMT Contract Manufacturing

Cost-Effectiveness: One key benefit of contracting out SMT manufacturing is cost-effectiveness. Economies of scale offered by contract manufacturers are difficult for independent firms to match. Outsourcing leads to considerable savings for companies by eliminating expenditures related to obtaining high-end machinery, maintenance, and manpower.

Access to Advanced Technology and Expertise: Both SMEs and large enterprises benefit from the expert knowledge and the leading-edge technology offered by contract manufacturers. Through this partnership, companies are able to have access to the latest manufacturing techniques with minimal direct investments, staying up to date with new innovations.

Scalability and Flexibility: The flexibility introduced by contract manufacturers allows companies to increase or decrease production in accordance with market demand without incurring unnecessary overhead. This flexibility is particularly crucial for companies with seasonal demand patterns or dynamic shifts in customer requirements.

Quality Assurance: Quality assurance is given top priority in contract manufacturing of SMT. Fabricators implement stringent standards during the manufacturing process, and every product has high standards of performance, reliability, and safety.

Focus on Core Competencies: By outsourcing SMT manufacturing, companies can devote more resources to core competencies such as research and development, product design, and marketing. This strategic focus leads to innovation and enhances competitiveness in the marketplace.

Case Study: SMT Contract Manufacturing in Action

Suppose a startup tech company has just had its revolutionary electronic devices suddenly increase in demand. With finite resources and an immediate need to increase production, the company resorts to SMT contract manufacturing. With its arrangement with a contract manufacturer, the company provides precise specifications for its products so that the producer can handle the details of component production.

The contract manufacturer, utilizing advanced SMT machines and highly skilled personnel, handles production requirements efficiently. The process is done step by step with testing and adjustments that guarantee quality products. In doing so, the tech company not only meets the market requirement in time but also significantly reduces overhead costs. This collaboration enables the company to invest more in its line of products and advertising.

Why Companies Use SMT Contract Manufacturing

Production outsourcing to SMT specialists depends on a series of factors. Companies with time deficits, insufficient resources, or poor investment prospects consider contract manufacturing as a strategic option. Contract manufacturing allows for efficient production operations, facilitating enterprises to save liquidity and focus on maximizing their market position.

Further, outsourcing ensures efficient cash flow within the economy of a firm, as resources can be allocated more efficiently across different business operations. Contract manufacturing also assists in eliminating the risks associated with rapid technological changes, as companies receive access to current technologies without the burden of huge capital expenditure.

Overall, SMT contract manufacturing is not merely a strategic option but an indispensable strategy for electronics businesses. As the dynamic industry continues to advance in complexity and demand, high-value and efficient manufacturing solutions become a necessity that renders SMT contract manufacturing a necessary business tool for companies focused on growth and innovation.

At PCBX, we recognize the importance of SMT contract manufacturing to maintain a competitive advantage in the rapidly changing electronics industry. With the benefits of this approach—cost reduction, access to new technologies, and enhanced production capacities—we empower our customers to adapt to contemporary needs and define future innovations.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Surface Mount Technology revolutionizes electronics, offering size, cost, and performance benefits, but poses challenges with high setup costs and handling.

Surface Mount Technology (SMT) revolutionized electronics, facilitating smaller, faster, and more reliable products. It mounts components directly on PCBs, enabling miniaturization and automation. Though SMT boosts space efficiency, cost-effectiveness, and reliability, it poses rework challenges and requires high initial investment.

Printed Circuit Board Assembly (PCBA) employs Through-Hole Technology (THT) and Surface Mount Technology (SMT). THT offers robust mechanical bonds, ideal for high-stress applications, whereas SMT supports efficient, high-density assemblies. Each method has unique advantages and limitations, impacting cost, manufacturing efficiency, and component compatibility. Understanding these differences is key for optimal PCB design.