PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

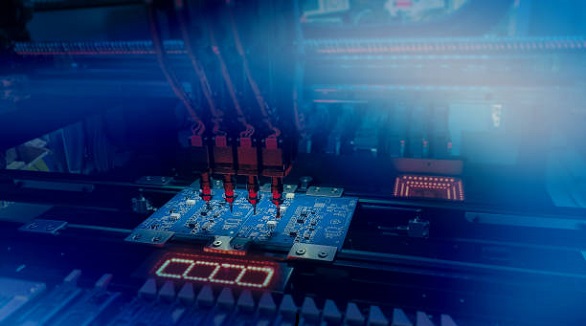

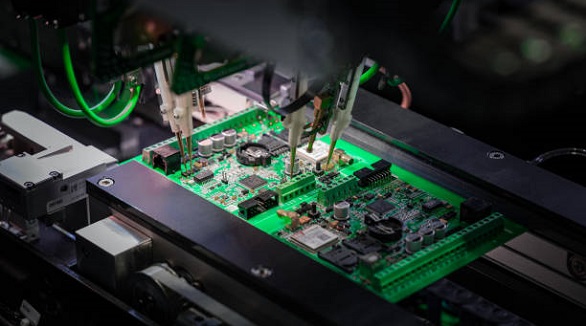

Effective ESD control in SMT assembly is achieved through proper grounding, use of antistatic materials, and routine testing to prevent damage to sensitive electronics.

Prepreg is crucial in multilayer PCBs, providing mechanical strength and electrical insulation to meet modern electronics' demanding requirements across industries.

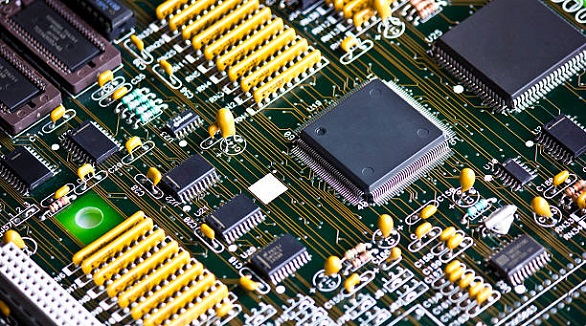

Mixed-technology PCB assembly integrates SMT, THT, and BGA to create compact, efficient electronic devices, meeting the growing demands for high-performance solutions.

SMT contract manufacturing boosts efficiency and lowers costs for electronics businesses, offering advanced technology access and allowing them to focus on essential operations.

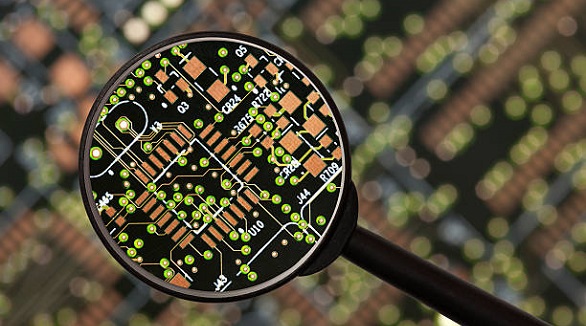

SMT footprints are critical PCB designs for mounting components directly, ensuring electrical connections and standardization, aiding efficient manufacturing.

BGA chips offer compact, high-performance mounting for PCBs, essential in modern electronics, but require precise handling and advanced inspection methods.

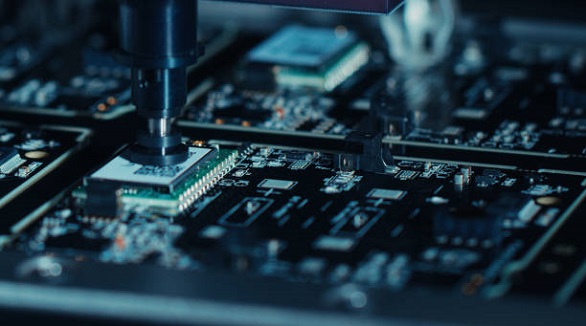

SMT ensures compact, reliable electronics production but requires precise quality control, advanced tech, and skilled workforce to maintain high standards efficiently.

Analog signals are crucial in electronics but susceptible to noise, which necessitates strategic PCB design to ensure high performance and signal integrity.