What is Mixed-Technology PCB Assembly?

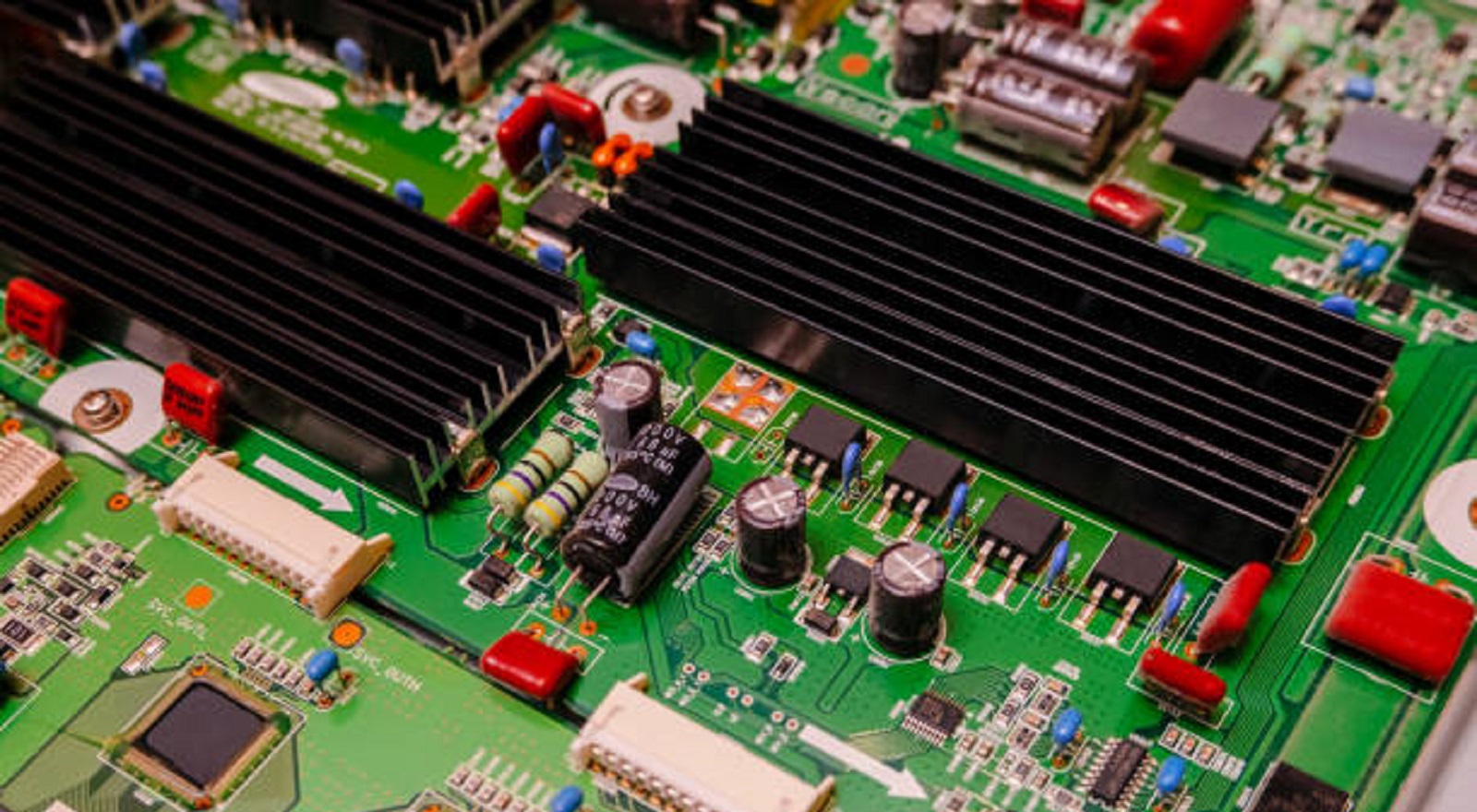

Mixed-technology PCB assembly integrates SMT, THT, and BGA to create compact, efficient electronic devices, meeting the growing demands for high-performance solutions.

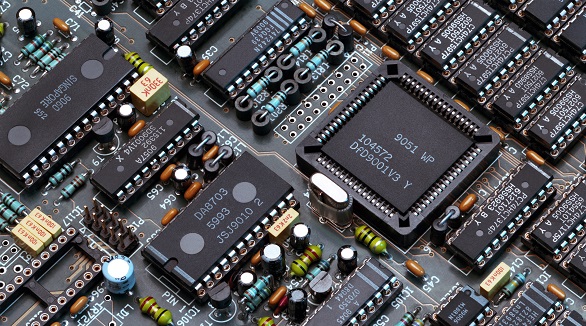

In the high-tech age of electronics today, high-quality, high-performance, and small-sized devices are most sought after. All this has led to innovative assembly techniques. That is where mixed-technology PCB assembly steps in - an extremely innovative technique that involves Surface Mount Technology (SMT), Through-Hole Technology (THT), and Ball Grid Array (BGA) packaging combined into a one-package solution. While SMT remains the superior technique due to its efficiency and cost, certain sections of the board call for other assembly techniques, so the application of hybrid assembly in today's electronic layout completely necessary

The Fundamentals of Mixed-Technology PCB Assembly

Mixed-technology PCB assembly, more popularly known as hybrid assembly, refers to the assembly of various mounting technologies on a single PCB. SMT is appreciated for its ability to accept high-speed production and high-density component placement, making it the darling of most modern applications. THT, however, enjoys an advantage in providing mechanical strength and ruggedness to components that are subjected to harsh mechanical or thermal stress. BGA packaging, a high-tech SMT application, allows high-density component placement with the additional advantage of more functionality without consuming additional space.

This procedure gives a singular integration of the most favorable aspects of the two technologies, achieved with no reliance on solder paste, the traditional hindrance in traditional assembly processes.

Advantages of Mixed-Technology PCB Assembly

Flexibility in Accommodation of Components: Hybrid assembly supports the ability to accommodate SMT, THT, and BGA components, giving flexibility in accommodating varied electronic requirements. This comes into specific usage in products requiring strong mechanical contacts or high-density integration.

Enhanced Design Flexibility: It allows RF and digital designs on a single PCB, which supports intricate circuitry and reduces design restrictions.

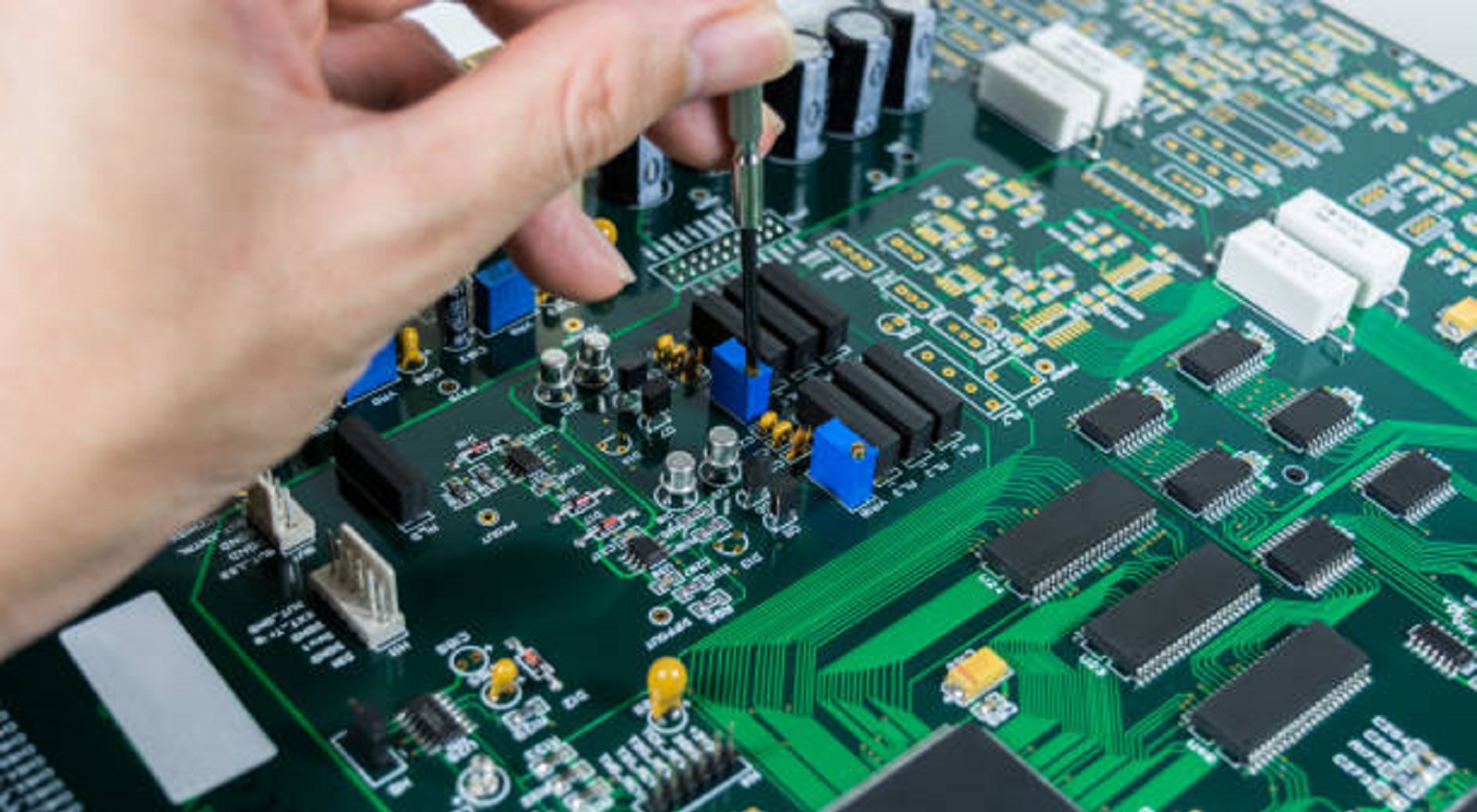

Operational Efficiency and Reliability: Automated methods facilitate immediate component placement for SMT, while manual methods ensure accurate placement for THT and BGA, enhancing reliability and reducing manufacturing cost in high-volume scenarios.

Miniaturization Customization: Allows miniaturization of designs, reducing bulk wire requirements and enabling lightweight high-precision electronic designs.

Better Performance Metrics: Offers better thermal and electrical performance, which is a critical factor for high-risk industries like aerospace and defense.

Avoiding the Pitfalls of Mixed-Technology PCB Assembly

Having a mixed assembly process implies that one needs to plan ahead in order not to fall into pitfalls:

Complex Design Requirements: Effective placement of components is needed to prevent conflicts and preserve performance. This involves adhering to design for manufacturing (DFM) and design for assembly (DFA) processes to ease the transfer of the design to production.

Sophisticated Equipment and Inspection: With the latest equipment, such as automated pick-and-place machines and careful inspection procedures like X-ray analysis, ensures high-quality output and error detection.

Optimal Process Workflow: It is advisable to have a well-organized workflow where automated as well as manual assembly processes are proportionately blended to achieve high efficiency, cost-effectiveness, and reliability.

Applications of Hybrid-Technology PCB Assembly

The flexibility and reliability of hybrid assembly render it highly suited to a wide range of applications in various industries:

LED Lighting Devices: Ensures maximum efficiency and miniaturization of light modules, which is crucial in the case of energy-saving solutions.

Telecommunications: Provides the high reliability and performance needed to support advanced networking hardware and communications infrastructure.

Medical Devices: Provides the accuracy and ruggedness required in sophisticated diagnostic and treatment devices.

Aerospace and Defense: Supplies the high performance and ruggedness needed in mission-critical applications where failure is not an option.

Consumer Electronics: Supports high-density integration required for smartphones and personal computer systems.

Best Practices and Design Rules for Mixed Assembly

Successful mixed-technology PCB assembly requires the incorporation of best practices and design guidelines addressing component placement and process nuances:

Unified Component Siding: Put as many components on a single board side as feasible in order to minimize confusion and conserve space.

Strategic BGA Placement: Do not put two BGA components back-to-back and leave a 5 mm clear space around each BGA for future test and re-soldering needs.

Proximity Management: Maintain an optimal distance between THT components and BGA devices to keep the design simple.

Weight Distribution: Distribute heavier components evenly to keep the board from bending and ensure structural integrity.

Standard Package Sizing: Utilize the same package size wherever it is applicable in order to optimize the assembly process and maintain consistency.

Partnering with Industry Leaders for Success

At PCBX, we embody excellence in mixed-technology PCB assembly through our investment in cutting-edge equipment and seasoned expertise in manufacturing and assembly. Our capabilities span across double-sided PCB assembly, rapid prototyping, and high-mix complex PCB assemblies. We emphasize complete traceability from order initiation to final product delivery, ensuring you receive nothing short of perfection.

With our high-tech inspection lab and emphasis on rapid delivery, we ensure faster turnaround times so you can reduce time to market and enhance competitiveness. Our dependability in meeting your individual requirements and adherence to industry standards makes us your best bet for handling the complexities of mixed-technology PCB assembly.

With technological advancements, there is a growing demand for smaller, more efficient, and more powerful electronic devices. Mixed-technology PCB assembly lies at the forefront of meeting these demands, posing a strategic approach to the design and production of advanced electronic solutions. By partnering with us at PCBX, you access industry best practices, leading solutions, and a commitment to excellence that makes your products shine in a competitive marketplace. Join the future with a strategic partner that understands the art of hybrid assembly and is dedicated to taking your business to the next level.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Through-hole assembly remains essential in electronics, offering strength and reliability, especially in critical applications, despite SMT's rise in compact designs.

Surface Mount Technology revolutionizes electronics, offering size, cost, and performance benefits, but poses challenges with high setup costs and handling.

PCBs enable miniaturization, efficiency, and cost-effectiveness in electronics. Automated assembly further reduces costs, enhances accuracy, speeds production, and ensures quality.