PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

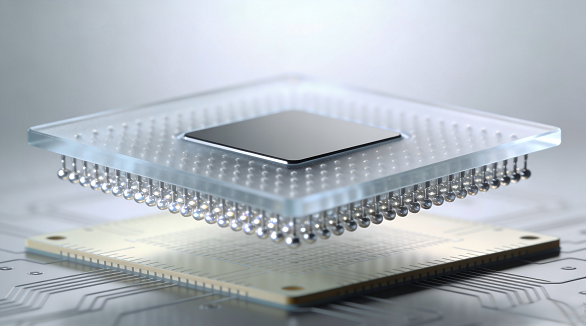

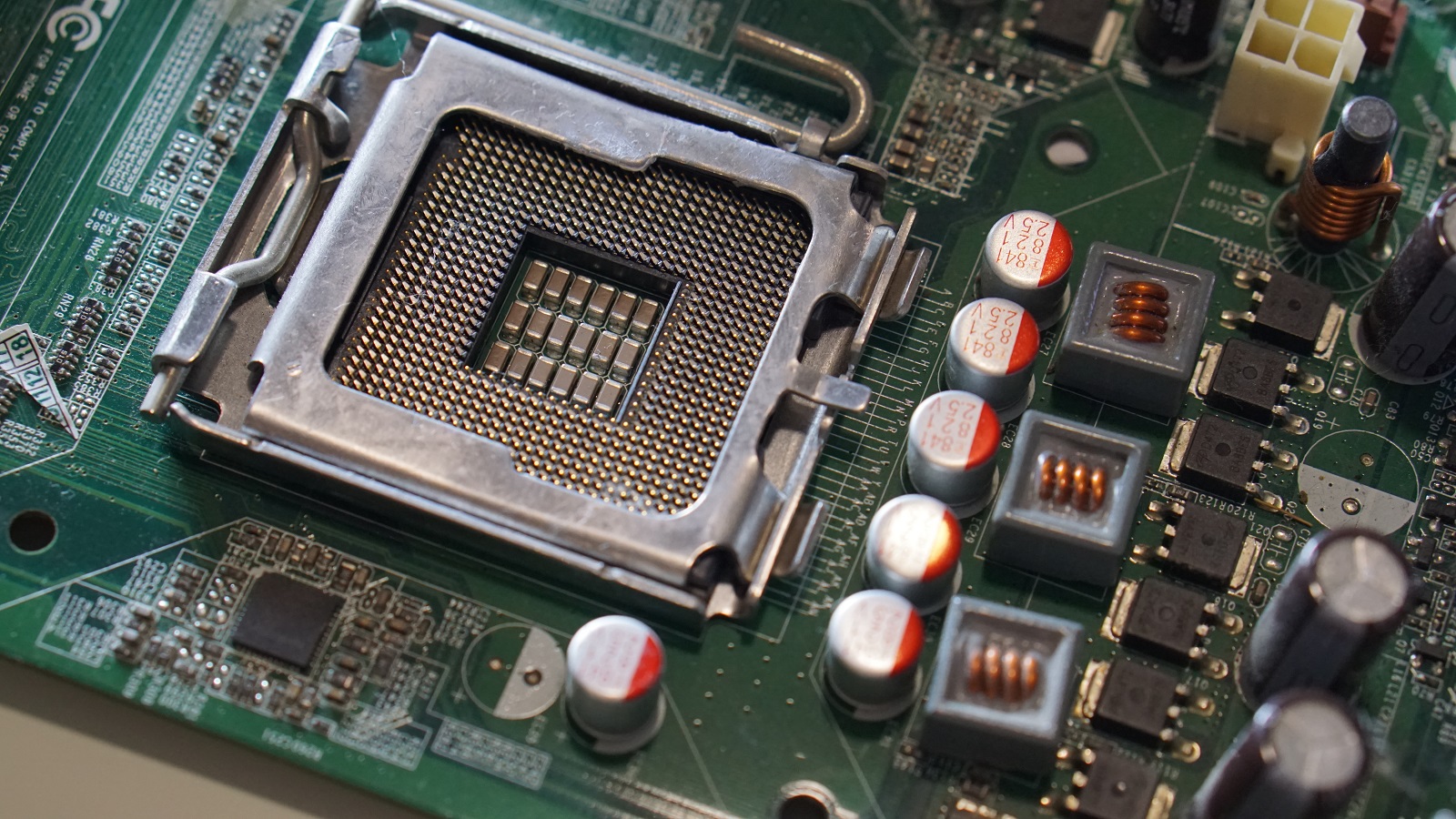

BGAs offer high-density interconnects and compact design, crucial for advanced electronics, but hidden solder joints complicate assembly, requiring precise methodologies.

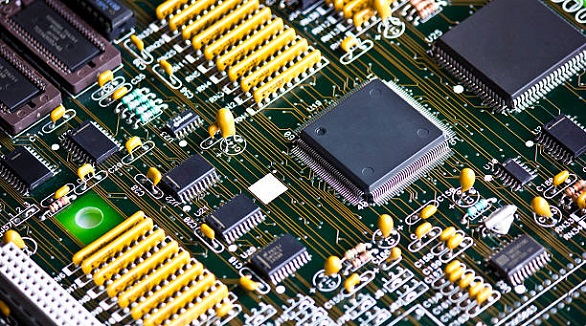

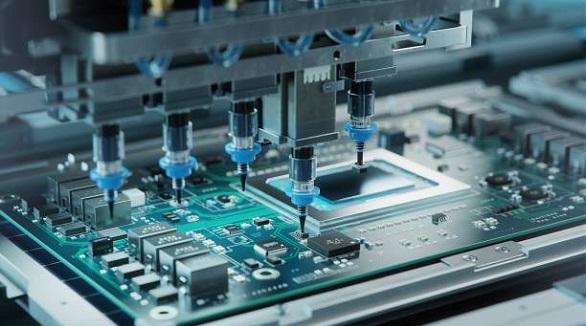

Mixed-technology PCB assembly integrates SMT, THT, and BGA to create compact, efficient electronic devices, meeting the growing demands for high-performance solutions.

BGAs are vital for compact, high-functionality devices, but demand meticulous routing to overcome design challenges in reliability, manufacturability, and signal integrity.

BGA chips offer compact, high-performance mounting for PCBs, essential in modern electronics, but require precise handling and advanced inspection methods.

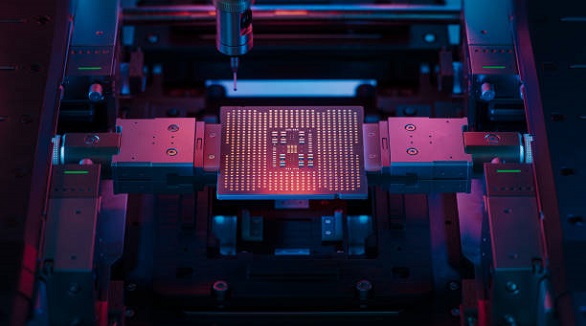

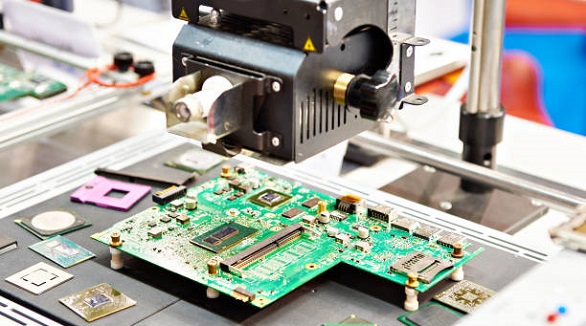

BGA reballing restores functionality to failed solder joints using precise tools and methods, crucial for compact devices facing thermal, physical, or environmental stress.

Pin in Paste (PiP) enables efficient, cost-effective PCB assembly, integrating through-hole and surface mount components in a single reflow pass, reducing costs.

Ensure SMT quality through detailed design, supplier rigor, and process controls, enhanced by testing and continuous improvement for reliable, defect-free products.

BGAs offer efficient, reliable IC connections with superior performance, comprising seven types ideal for high-performance electronics, optimizing space and thermal efficiency.