How to Improve SMT Assembly Quality?

SMT ensures compact, reliable electronics production but requires precise quality control, advanced tech, and skilled workforce to maintain high standards efficiently.

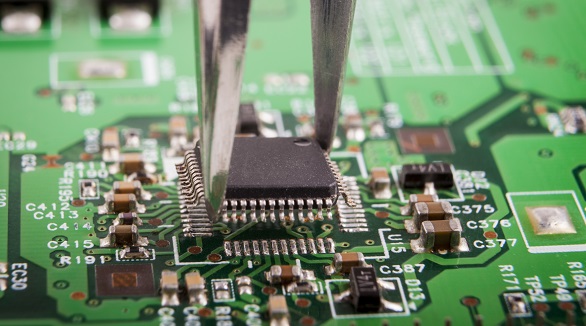

Surface Mount Technology (SMT) is the backbone of modern electronics manufacturing which helps to manufacture smaller, more complex, and reliable electronic devices. While it has many advantages, high-quality SMT assembly is not easy and needs precise quality enhancement strategies. This guide provides an overview of effective procedures to maximize SMT assembly quality to ensure sustained excellence in electronic products.

Understanding SMT Assembly

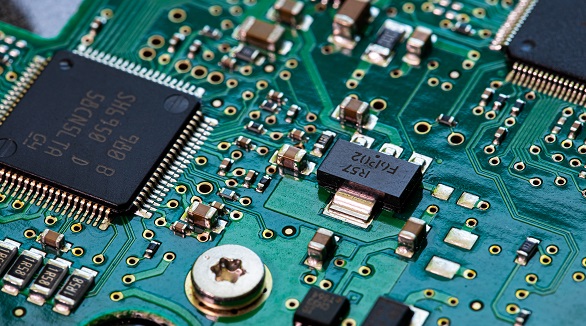

SMT assembly involves the mounting of components onto the PCBs themselves, which has benefits including increased component packing density, reduced product size, improved electrical performance, increased production speeds, and reduced cost of production. However, its complexity requires stringent quality control to produce desired outcomes.

Key Factors Affecting SMT Assembly Quality

Component Quality: Component reliability is paramount in SMT assembly. Major points are rigorous adherence to specifications, appropriate storage and handling procedures, and good supplier quality control. Reputable suppliers and stringent incoming inspection are imperative strategies.

PCB Design and Quality: PCB design plays an important role in the success of assembly. Proper material selection, trace width optimization, and thermal management are crucial. They influence the manufacturability and reliability of the completed product.

Solder Paste Application: Solder paste application is critical in the development of strong solder joints. Stencil design, type of paste, and precise printing conditions are all significant considerations. Equipment maintenance and maintaining consistency of solder paste viscosity are crucial practices.

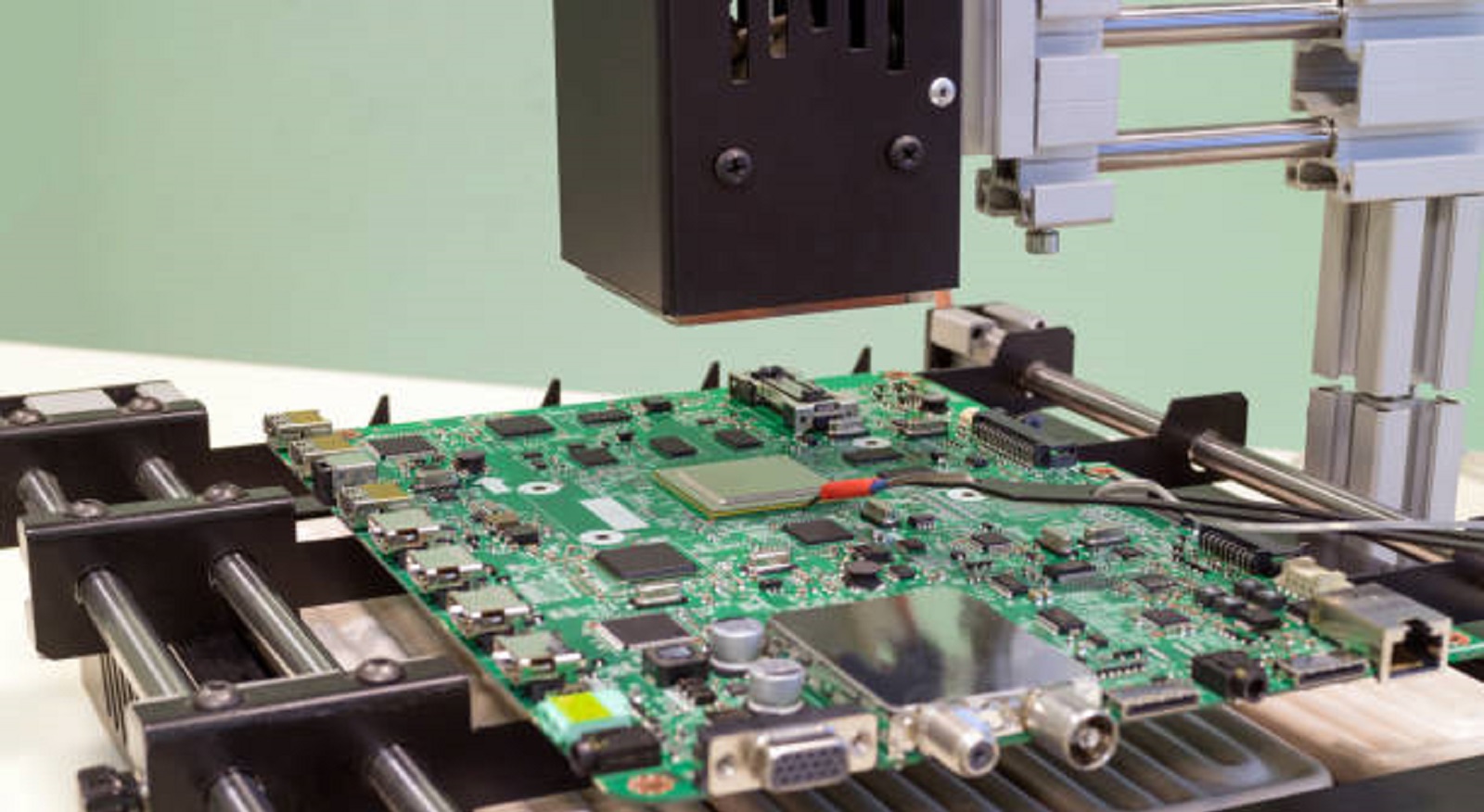

Component Placement: Accurate placement of components is essential to high-quality assemblies. This involves maintaining the calibration and precision of pick-and-place machines and maintaining component feeders in operational condition. Regular calibration of the equipment avoids misalignment.

Reflow Soldering: A reliable reflow process produces solid solder joints. Oven profile design parameters and controlled cool-down rates influence the quality of the soldering process, demanding complete thermal profiles for different types of assemblies.

Process Optimization Techniques

Design for Manufacturability (DFM): Applying DFM principles at the initial design stage ensures assembling reliability. By prioritizing component selection and pad layout standardization, it enables easy inspection and rework, permitting design teams to 'design out' problems in advance.

Statistical Process Control (SPC): Application of SPC tools proactively identifies and rectifies process deviations. Control charts and root cause analysis enable process stability and minimize defects, enhancing overall quality.

Poka-Yoke (Error-Proofing): Error-proofing techniques like the use of barcodes to scan for checking and sensors to identify misalignments can remove common assembly errors. Such systems add accuracy and reduce the chances of human error.

Process Documentation and Standardization: Extensive documentation, including detailed work instructions and quality inspection procedures, provides production consistency. Thoroughly documented process ensures adherence to standard practice, which is crucial to ensure quality.

Quality Control Measures

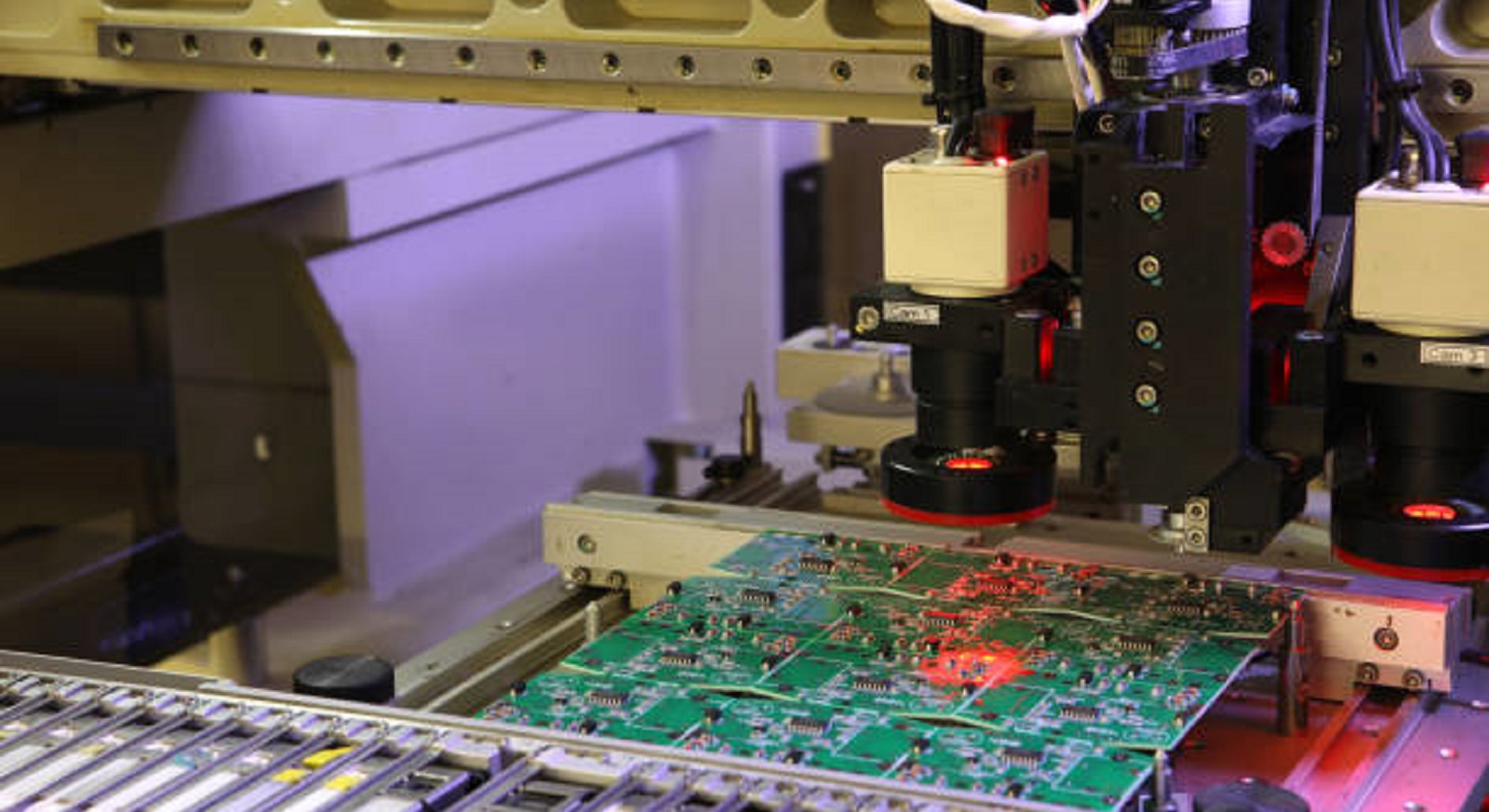

Automated Optical Inspection (AOI): AOI equipment quickly identifies defects, providing consistent assurance of defect-free products using high-speed inspection and real-time indication.

X-ray Inspection: Useful for checking covered solder joints in packaged devices like BGAs, X-ray inspection offers non-destructive testing to detect voiding or bridging.

In-Circuit Testing (ICT) and Functional Testing: ICT and functional testing ensure component location and functionality. ICT quickly identifies electrical failures, while functional testing simulates normal operation to verify performance.

Data Collection and Analysis: Having in-place real-time data collection and analysis systems discloses trends and quality improvement areas. Advanced analytics identify root causes, allowing for targeted interventions.

Advanced Technologies and Workforce Development

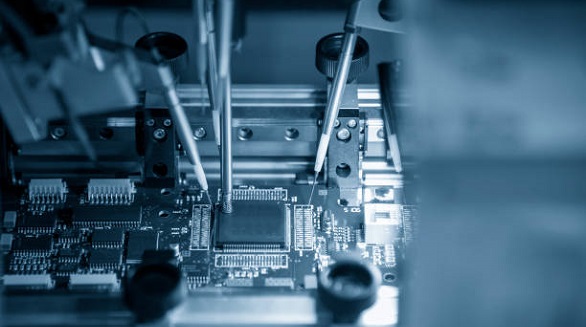

3D Solder Paste Inspection (SPI): Application of SPI technologies to track solder paste volume and alignment fosters issue detection at an early point, reducing resultant soldering defects and enhancing quality control.

AI and Machine Learning: Leverage AI to automate defect detection, enhance inspection accuracy, and optimize process parameters to significantly improve quality. These technologies enable proactive compensation and reduce errors.

Training and Workforce Development: Investment in quality awareness training and technical skills training fosters a culture of continuous improvement. SMT techniques, equipment operation, and defect correction must be included in training.

Environment and Cost-Effective Strategies

Environmental Conditions: Controlled environmental conditions, temperature, humidity, and ESD protection are critical. These play a major role in affecting manufacturing processes and product reliability.

Economically Achievable Improvements in Quality: Regular process audits, preventive maintenance, and lean manufacturing concepts can be employed to enhance quality at a reduced cost. Incremental efficiency gains often result in high-quality returns.

Current Trends in SMT Assembly Quality

Current trends such as miniaturization, bendable electronics, green manufacturing, and augmented reality will have an impact on SMT quality. The implementation of technological advancements will make SMT processes more streamlined and responsive to evolving market demands.

Improving SMT assembly quality involves an integrated process that involves process optimization, integration of advanced technology, and employee development for industries like PCBX. By embracing such methods, manufacturers uphold quality standards, with high-quality electronic products that meet the requirements of electronics markets.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

SMT enables miniaturization in electronics manufacturing but presents defects that need identification and resolution to ensure product quality and efficiency.

SMT assembly streamlines electronics manufacturing with compact, reliable designs using precise equipment, meeting high-density demands and international standards.

Still, SMT can further feature defects such as solder bridging, cold solder joints, tombstoning, and solder balling. Grasping the very common faults and their solutions is the key toward effective PCB assembly and reducing SMT errors—very much in line with the trend toward PCB miniaturization and higher component density.