Tooling Holes in PCB

Tooling holes in PCBs ensure precision and stability, reduce costs, and enhance manufacturing efficiency, playing a crucial role in high-quality production.

Printed Circuit Boards (PCBs) are the backbone of modern electronics that propel our world. While their electrical design typically gets a lot of attention, the physical aspects, such as tooling holes, are just as crucial in defining the precision, efficiency, and reliability of PCB manufacturing. At PCBX we understand the integral role these holes play, and in this comprehensive guide, we will examine their applications, attributes, and significance.

What Are Tooling Holes?

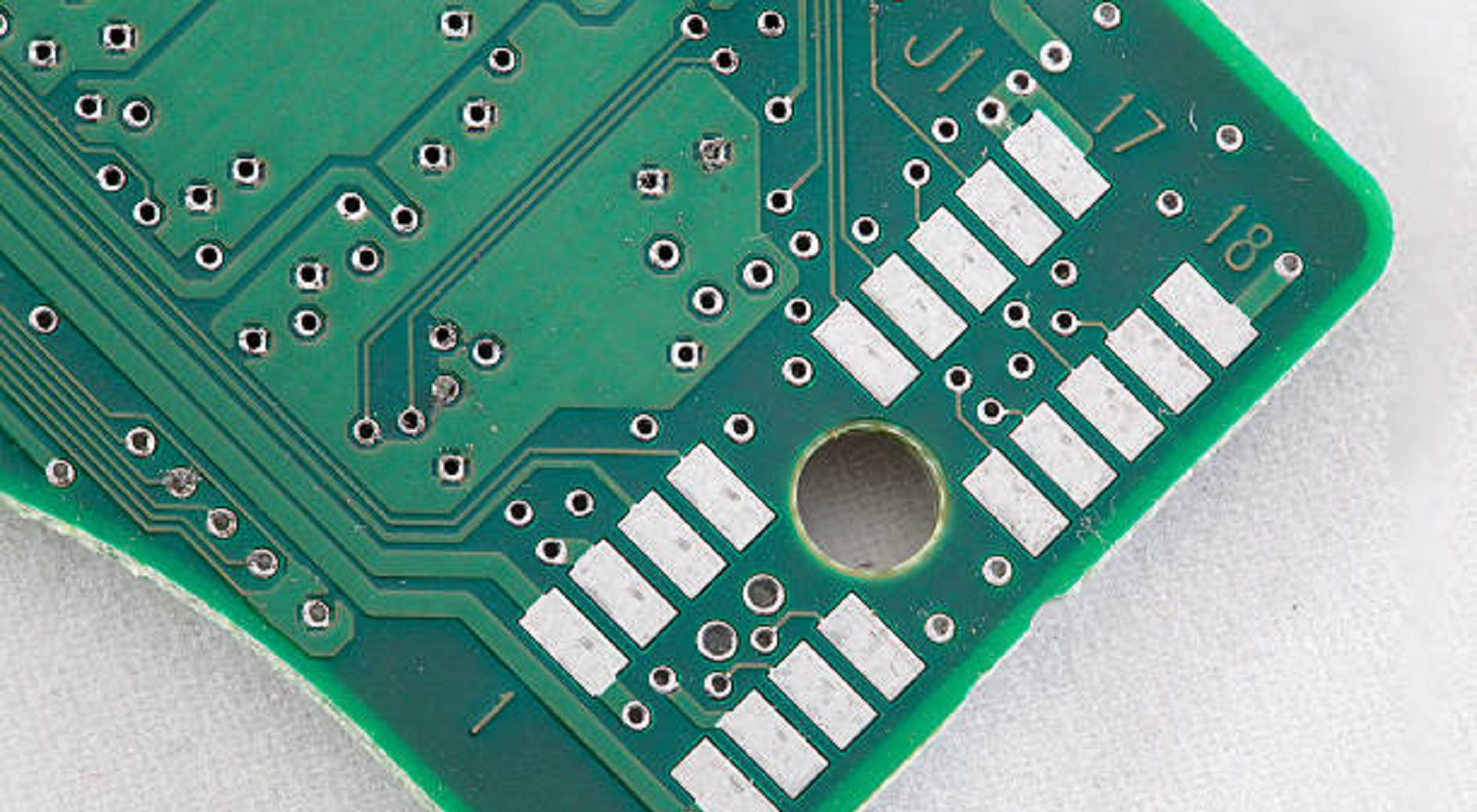

Tooling holes, also referred to as mounting holes, are strategically located holes, typically at the corners or edges of a PCB. They are un-plated holes, thereby differentiating them from the majority of the rest of holes on a board, and serve primarily mechanical, rather than electrical, purposes in manufacturing. Their primary purpose is to aid the accurate alignment and solid attachment of PCBs at several stages of manufacturing and assembly.

Functions and Benefits of Tooling Holes

Accurate Alignment and Assembly

PCB assembly, especially that of multilayer PCBs, requires precise alignment. Tooling holes are important in enabling proper registration of the different layers of a multilayer PCB. Tooling holes help to maintain components at a fixed position when placing components, thus reducing possible errors as a result of misalignment. This kind of precision is necessary when dealing with complex boards that need strict specifications.

Precise Positioning

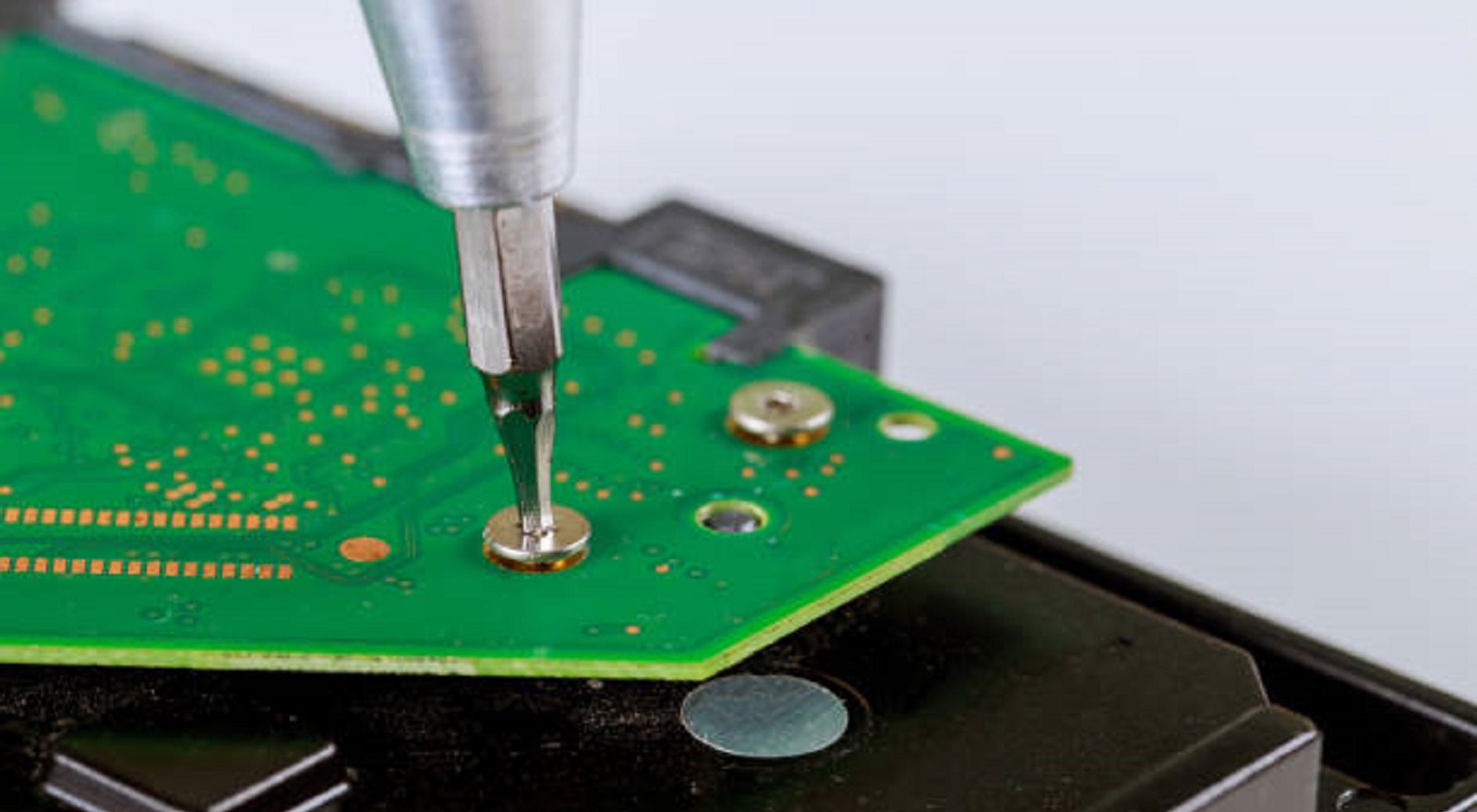

One of the essential functions of tooling holes is to precisely position the PCB in assembly machinery. It minimizes motion and vibration through processing, avoiding components from getting misplaced and damaged. This stability is especially required during processes like solder paste application and soldering, where the board needs to be held still.

Efficient Drilling and Soldering Processes

In drilling, tooling holes act as strong guides to provide maximum accuracy while holes are drilled. This is vital because even minor misalignments create defects. In soldering, they act as mechanical anchors, utilized in holding back recalcitrant components. This not only aids the reliability of the physical interfaces but also ensures long-term functionality and durability.

Cost reduction and minimizing waste

Cost-effectiveness is essential in production. Cost reduction is achieved with considerable contribution by tooling holes by optimizing material usage and eliminating waste where possible. By accurate processing and reduced error rates, producers can produce batches more economically. The advantage is of greater importance as larger-scale production is involved where marginal costs per unit become enormous overall savings.

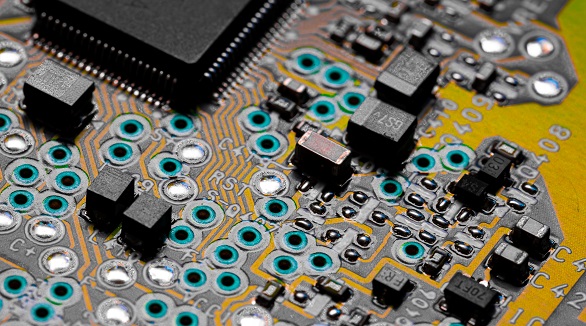

Maximum Performance and Reliability

Tooling holes help ensure the optimum electrical performance by ensuring that all components are placed in position and attached securely. This reduces the possibility of failure of solder joints and other types of defects that may lead to operational failure. By preventing such errors, tooling holes facilitate higher reliability and longer life of the PCB.

Importance in PCB Manufacturing

Faster Production Times

Saving of assembly time is one of the most significant advantages of utilizing tooling holes in PCB design. Tooling holes, by facilitating correct alignment and reducing the need for manual adjustment, allow production cycles to be quicker. This quickness is especially crucial in fulfilling tight deadlines and filling large orders because it helps the manufacturers respond promptly to customers' demands.

Enhanced Quality Control

Tooling holes are also essential in quality control processes, allowing confirmation that the assembly meets high tolerances and standards. Through accurate manufacturing, the holes allow for correct positioning of the components and correct execution of the assembly process. Correct tooling hole positioning ensures overall quality assurance and provides every board ready for sale to the customer upon delivery.

Effective Space Utilization

As miniaturization becomes a trend in electronics, optimum utilization of space in PCBs is more important now than ever. Tooling holes allow for maximum component positioning, allowing designers to achieve maximum utilization of available board real estate. This is paramount in small designs where there is little space for spacing, and the ability to accommodate all the necessary components is enabled without loss of functionality.

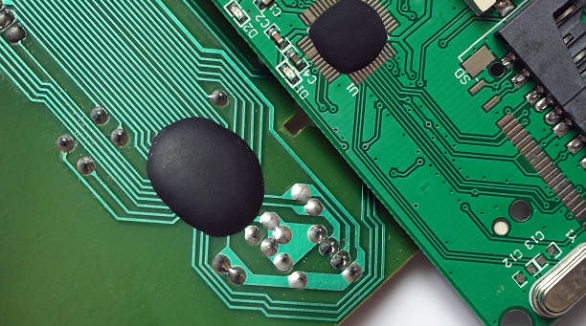

Permits Proper Component Placement

With progressively more complex designs that include multiple transformers, intricate wiring schemes, and sets of connectors, accurate positioning of components is essential. Tooling holes enable ideal component placement according to the design, with reduced chances of electrical shorts or mechanical failure.

Prevention of Electrical Shorts

Tooling holes also play a role in keeping the structural integrity of the PCB intact, providing it with the stability it requires so that electrical shorts are avoided. Tooling holes reduce the likelihood of short circuits resulting from misaligned or closely spaced components by enabling good routing of traces and proper component placement. This safeguard promotes device reliability and safety, manufacturer reputations, and end-user experience.

Tooling holes are a core aspect of PCB design and manufacturing processes and offer many benefits including better alignment and safe positioning to reduced cost and high rate production. At PCBX, we value the revolutionizing potential that precise incorporation of tooling holes has in maximizing electronic products' functionality and reliability. By leveraging these primary design elements, manufacturers are able to consistently deliver high-quality, dependable PCBs that meet demanding industry requirements and exceed user expectations. In a highly competitive market environment, the astute use of tooling holes can differentiate successful PCBs, making it a savvy investment for any creative manufacturer.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Counterbores and countersinks ensure fastener accuracy, crucial for aesthetics and stability in electronics, aiding structural integrity and space management.

Non-plated through holes provide mechanical support in PCBs but pose stress and precision challenges, requiring careful design, materials, and manufacturing.

PCBs are central to electronic devices, featuring holes and vias critical for functionality. Holes, like through-holes and mounting holes, serve electrical or mechanical purposes, while vias ensure electrical connections across PCB layers. Understanding their differences is key for optimal performance, reliability, and manufacturability in PCB design.