Understanding EMI Protection in PCB Manufacturing

EMI protection in PCB manufacturing ensures device reliability and compliance by using shielding, design optimization, and filtering to mitigate electromagnetic interference.

In today's technological world, electronic devices are everywhere, connected to our everyday lives. But with this increasing utilization of technology comes a very vital challenge-electromagnetic interference, EMI. EMI can considerably affect the performance of electronic devices, from malfunctioning to degraded performance. In the field of PCB manufacturing, understanding EMI protection will be important regarding ensuring reliability and compliance. The article provides an overview of EMI protection in manufacturing PCBs, the importance, types of interference, and how it can be mitigated.

What is Electromagnetic Interference (EMI)?

Electromagnetic interference, or EMI for short, is an interference in an electrical circuit caused by some form of electromagnetic radiation emitted from an external source, either intentionally or unintentionally. The source of this interference may be natural, originating from lightning or solar storms, and it may be human-made, emanating from electrical circuits and industrial equipment. When such disturbances occur at specific radio wave frequencies, they are often described as radio frequency interference or RFI.

Importance of EMI Protection

Maintaining Signal Integrity

EMI can cause signal distortion or deterioration within a PCB, which leads to functional glitches, mainly in high-speed digital and RF circuits. Effective EMI protection ensures that signal integrity is maintained, allowing devices to function with accuracy and reliability.

Ensuring Compliance

EMI emissions from electronic devices are required to be limited by standards set by bodies like the FCC in the United States and ETSI in Europe. The need to ensure not only market access but also consumer safety means that EMI protection plays an indispensable role within the manufacturing process.

Optimizing Performance and Reliability

The shielding of EMI is crucial to preserve the intended performance of electronic devices and avoid disruption that may cause user dissatisfaction, product recalls, or safety issues in critical applications.

Types of EMI

Narrow-Band EMI

It acts on discrete frequencies and is common in devices like radios, mobile phones, and televisions. It is controllable, however, by proper tuning and certain changes in design; it still causes malfunctioning of devices.

Broadband EMI

This type of interference occurs in a wide frequency range and is more dangerous for the operation of devices. It can be caused by malfunctioning motors, power lines, or even atmospheric disturbances, making it quite a tough issue to deal with.

Sources of EMI

Natural Sources

The natural causes of EMI are thunderstorms, solar flares, and cosmic radiation. Modern devices are designed to resist natural EMI, but these interferences can still affect older equipment and RF communication.

Man-made Sources

Most electric devices and industrial machinery generate EMI. This occurs due to the interference of signals, mainly at the overlap of frequencies. Common contributors include motors, power lines, and wireless transmitters.

Inherent/internal EMI

Internal EMI results from interference between device components. Such internal noise is a common problem and poses a significant challenge to design engineers.

Implementing EMI Protection in PCB Manufacturing

Material and Construction Techniques:

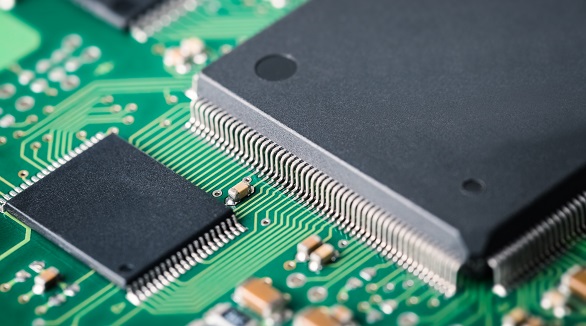

Some of the most common EMI shielding materials used in PCB design include copper, aluminum, and alloy 770, all of which can provide a protective barrier against EMI interference in sensitive areas.

It includes polycarbonate or metal enclosures with enhanced protection and EMI-shielded gaskets, making them conductive barriers against EMI.

Design Strategies for EMI Reduction:

Layer Stacking and Grounding: Incorporating solid ground planes in multi-layer PCBs reduces loop inductance and minimizes coupling effects, providing a return path for current.

Optimized Trace Layouts: Careful routing of traces reduces the areas that are susceptible to EMI. Such techniques as differential signaling further reduce noise by cancelling out interfering signals.

Use of Filtering and Protective Components:

Low-pass filters and ferrite chokes are used to block unwanted high-frequency noise and thus suppress EMI on power and signal lines.

Capacitors and Resistors: These components are placed strategically to reduce EMI by filtering and managing voltage spikes, thereby diverting interference signals from sensitive parts.

Tools and Techniques for Comprehensive EMI Protection

EMI Shielded Cables: These cables minimize susceptibility to interference and are an essential component in achieving comprehensive protection.

Conductive Coatings: Spray-on conductive coatings with metals like nickel or copper add a layer of EMI resistance to non-conductive materials.

Electronic Filters: Integral to many critical components, these filters selectively accept desired frequencies while rejecting unwanted signals, enhancing overall device performance.

Importance Across Industries

EMI protection is crucial, not only in consumer electronics, but also in industries such as automotive, telecommunications, and aerospace and defense. Robust EMI protection ensures the smooth operation of sophisticated systems and infrastructure within these industries, from autonomous vehicles to aerospace equipment.

Effective EMI protection is instrumental in PCB manufacturing, ranging from product reliability to ensuring regulatory compliance and meeting consumer satisfaction. Basically, the deployment of advanced material, intelligent design considerations, and strategic component placement helps counter the challenges posed by EMI. PCBX is at the forefront of this effort, leveraging the most advanced techniques and materials to deliver superior EMI protection in all its PCB solutions, safeguarding electronic systems in an increasingly electromagnetic environment.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

PCBs require rigorous reliability testing to ensure long-term durability, performance across industries, and standards compliance, minimizing failure risks.

IPC standards ensure PCB quality by guiding solder mask application, focusing on material properties, performance tests, classifications, and coverage criteria.

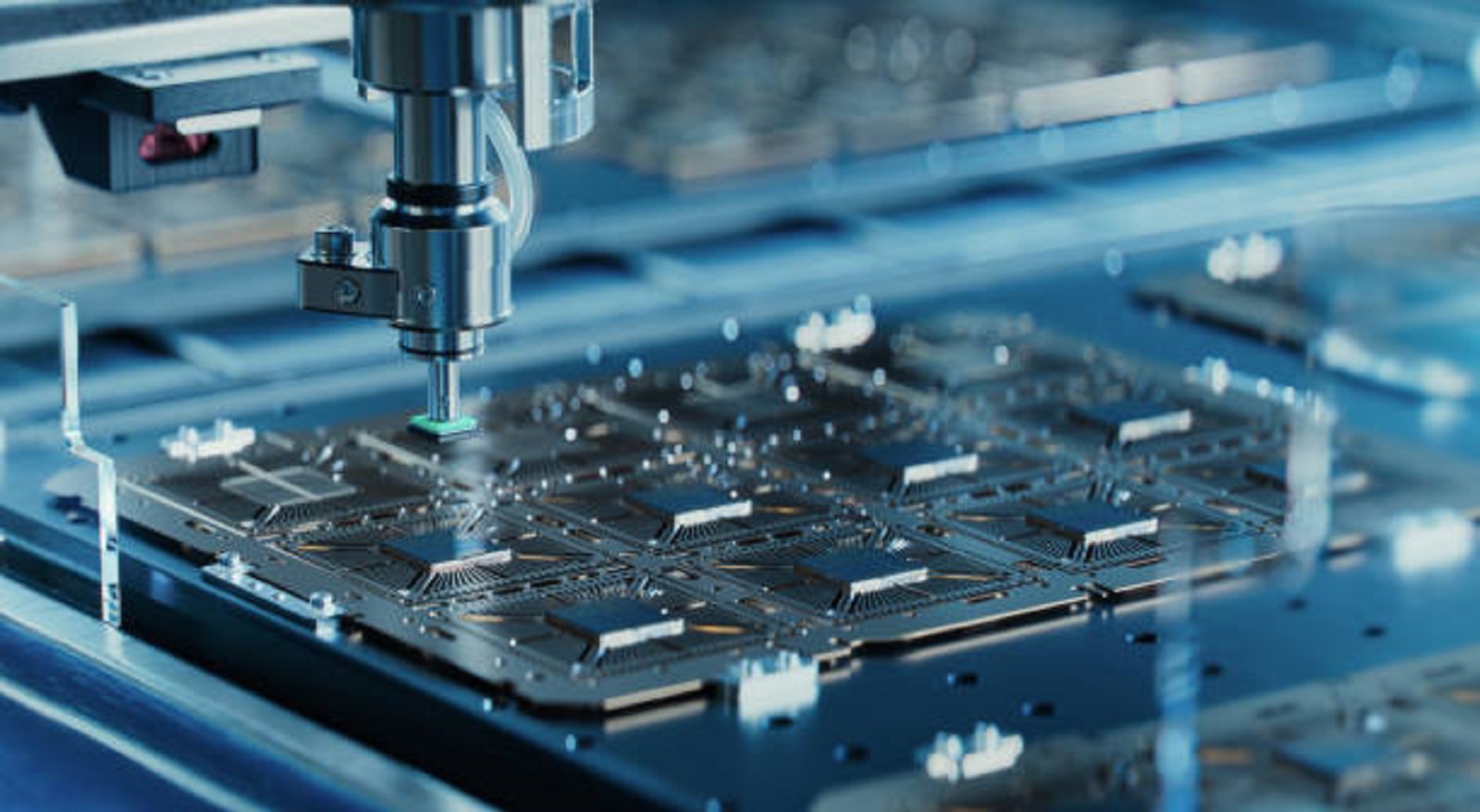

Surface Mount Technology (SMT) revolutionized electronics, facilitating smaller, faster, and more reliable products. It mounts components directly on PCBs, enabling miniaturization and automation. Though SMT boosts space efficiency, cost-effectiveness, and reliability, it poses rework challenges and requires high initial investment.