What is LCD PCB Interface?

The LCD PCB interface is crucial for efficient, reliable displays, connecting control circuits to the display and impacting device performance and user experience.

In the modern age of electronics, displays determine to a large extent how users experience their devices. From smartphones and television sets to industrial machines and calculators, displays present useful information and enhance user experience. Among the most prevalent display technologies is the Liquid Crystal Display (LCD), renowned for being clear and efficient. At the heart of an LCD's functionality lies the LCD PCB (Printed Circuit Board) interface, a complex device that interfaces displays with electronic systems. This article explores the functionality of the LCD PCB interface, its constituents, and its significance in the field of electronic communication.

What is an LCD?

In understanding the LCD PCB interface, it is necessary first to understand the LCD. An LCD, or Liquid Crystal Display, is a flat panel technology that employs the use of liquid crystals in light modulation. The display is famous for its capacity to project clean images and consume very little power, which is why they are so applicable to many different uses—be it watches and TV sets, computer monitors and industrial displays.

The Role of PCB in LCD Technology

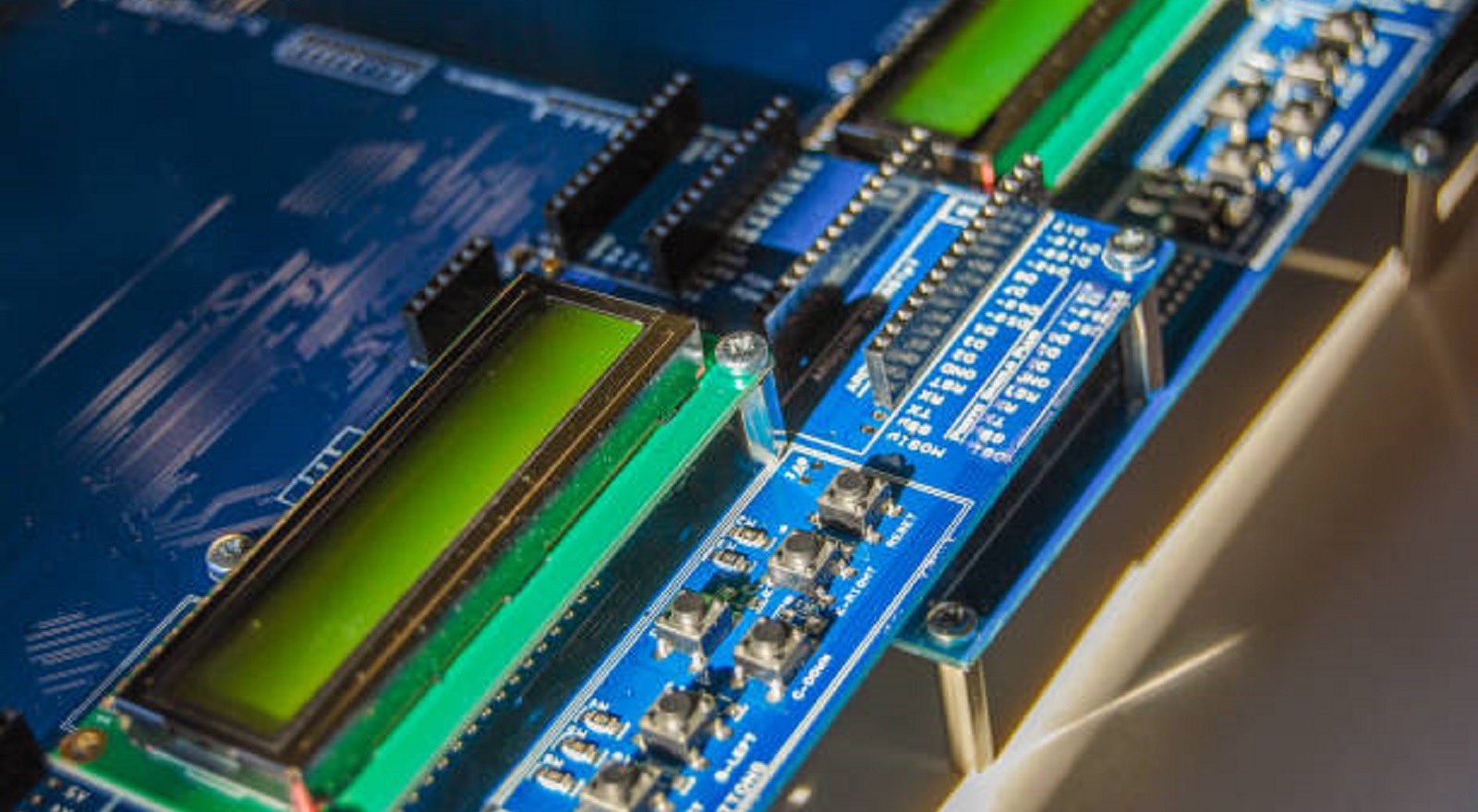

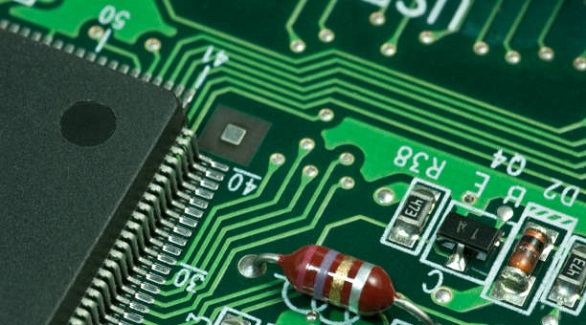

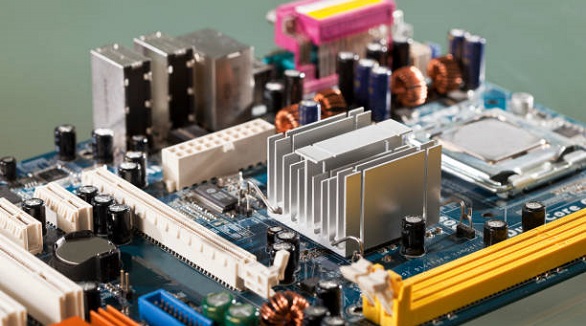

Printed Circuit Boards (PCBs) are the support for most electronic devices since they provide a structured base to mount electronic components and establish electrical connections between them. PCB plays a key role in LCDs to hold the driving circuits that control the display functionality. PCBs manage essential functions such as signal processing, voltage regulation, and communication of data with the central processing unit. This ensures the display operates effectively, presenting the necessary visual data correctly and effectively.

LCD PCB Interface Components

Driver ICs:

Driver Integrated Circuits are components of the LCD PCB and are responsible for generating the signals used to control the pixel states of the display. They convert digital signals from a processor or microcontroller to analog signals used to drive the orientation of the liquid crystals, which influence the quality and sharpness of the image.

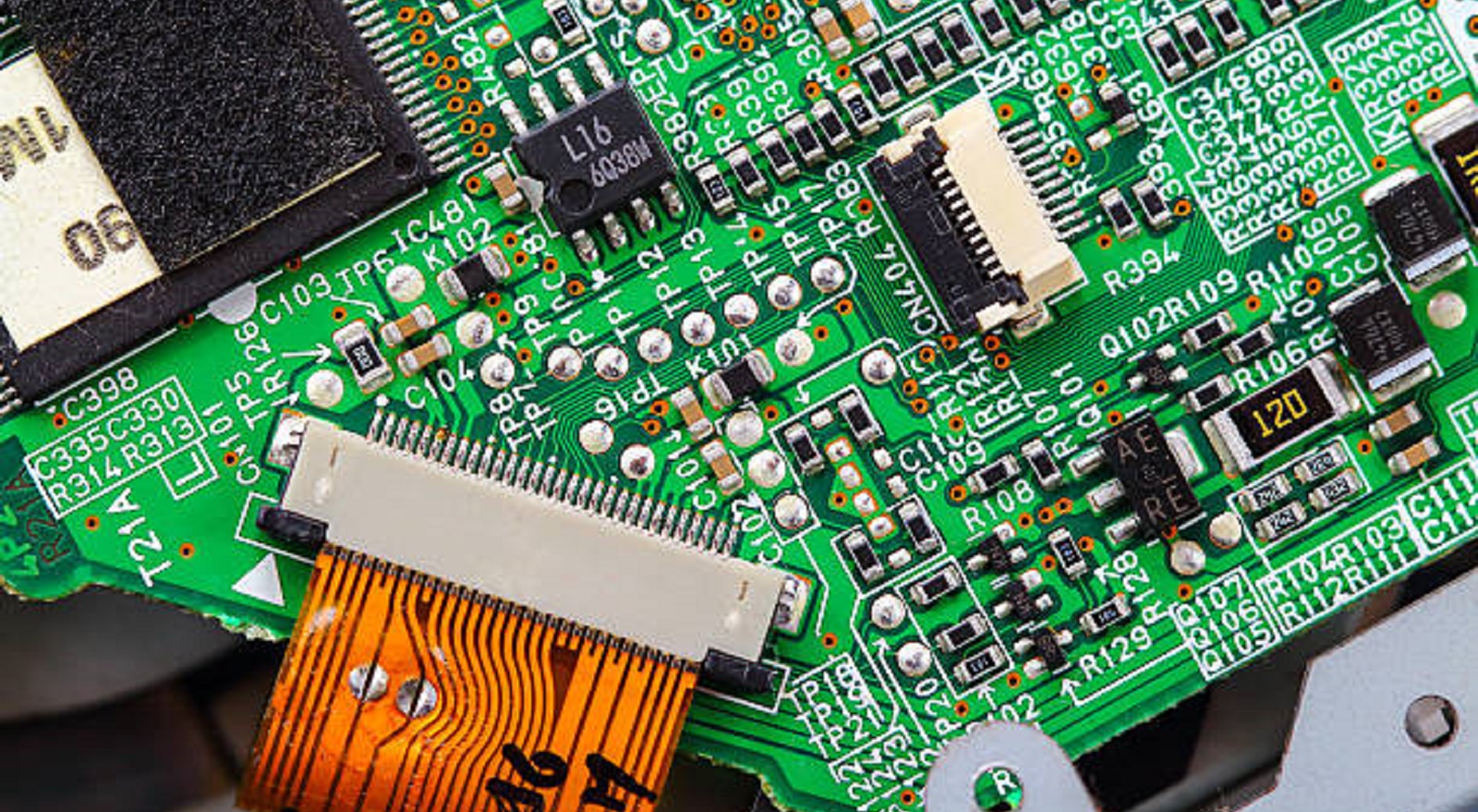

Connectors:

Connectors, either Flexible Flat Cables (FFC) or Flexible Printed Circuits (FPC), connect the LCD to the PCB. The connectors provide safe data transfer while retaining the mechanical flexibility needed for today's compact device designs.

Backlight Control Circuitry:

LCDs rely on a backlight to light up the display. The PCB has circuitry that manages the intensity and distribution of this backlight, typically using energy-saving LEDs. Adjustable based on the level of ambient light, this circuitry maximizes display brilliance and power efficiency.

Voltage Regulators:

To function properly, LCDs need certain voltage levels. Voltage regulators on the PCB control the power supply so that the display has a constant source of power irrespective of input voltage fluctuations, thus improving reliability and life.

Microcontroller Interface:

The microcontroller interface within the PCB controls communication between LCD and the central processing unit of the device. It employs protocols such as I2C, SPI, or parallel interfaces based on the data speed and complexity required for the display.

Types of LCD PCB Interfaces

Parallel Interface:

One of the simplest and oldest methods, the parallel interface connects an LCD to a PCB via multiple data lines for transmitting bits simultaneously. Even though it offers high data transfer rates, it is less favored for small devices due to the pins it requires.

Serial Interface:

Serial interfaces like SPI and I2C reduce data lines by transmitting data one at a time, making them ideal for space-constrained devices. While they tend to offer lower data rates than parallel interfaces, their ease of implementation and efficiency are an advantage in small devices.

LVDS (Low Voltage Differential Signaling):

This is applied in big and high-resolution displays, where LVDS uses differential signaling to transmit data at high speeds with low electromagnetic interference, ensuring signal integrity for distances.

MIPI (Mobile Industry Processor Interface):

Increasingly used in mobile phones, MIPI provides for high-speed data transfer with low power consumption, and is particularly well-suited to high-resolution displays in small enclosures.

Importance of the LCD PCB Interface

The LCD PCB interface is a determining factor in the performance and reliability of a display. A well-designed interface ensures smooth communication between the processor and the display, resulting in responsive, clear images, and power management. It directly impacts user experience, especially in handheld devices where responsiveness and battery life are critical parameters.

Challenges and Considerations

Designing an efficient LCD PCB interface involves addressing some challenges:

Signal Integrity: It is necessary to maintain signal integrity, particularly in high-speed applications. The designers must consider the line impedance, crosstalk, and electromagnetic interference.

Thermal Management: Since the devices are becoming smaller, there is a need to manage the heat that is being generated by the driving circuits and backlighting components to provide performance and durability.

Cost and Complexity: The cost and complexity of the interface relative to desired performance and form factor need to be balanced, especially for consumer electronics where cost-effectiveness is the concern.

The LCD PCB interface is the building block of modern display technology, linking the electronic control circuits and the visual output to the user. Understanding its parts and functions allows designers to create more efficient, reliable, and more stunning products that optimize the user experience. As technology progresses, innovation in creating more sophisticated and energy-efficient interfaces remains an exciting frontier.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Current limiting circuits are crucial in PCB designs, preventing overcurrent damage and ensuring safe, reliable operation across various electronic applications.

Burn-in boards are vital for testing semiconductor reliability, simulating stress to reveal defects, ensuring high-quality devices before mass production.

Carrier PCBs are crucial for data modulation, multiplexing, and network integration, supporting efficient and robust telecom infrastructures globally.