PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

FPC stiffeners provide rigidity to prevent deformation, protecting components and ensuring reliability in flexible circuits used in electronics and wearables.

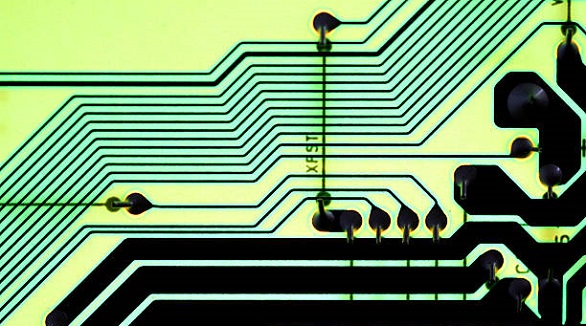

PCB design hinges on safe spacing for reliability; it prevents short circuits and ensures durability, addressing both electrical and non-electrical factors.

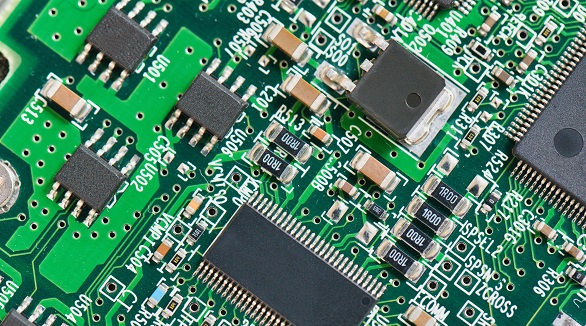

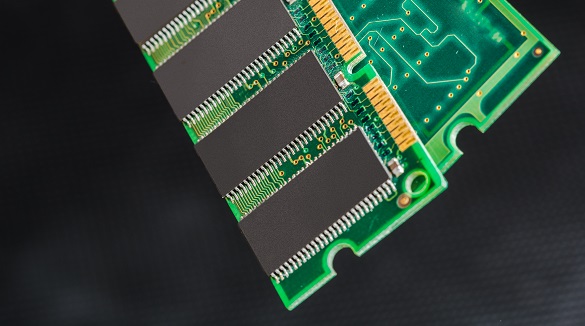

FR-4 is a cost-effective, versatile PCB material, ideal for consumer electronics and prototyping but unsuitable for high-frequency or temperature needs. Consider thickness, flexibility, and impedance.

Understanding and correctly specifying PCB drill sizes ensure board functionality and manufacturability. Drill sizes affect electrical connections, stability, and signal integrity in PCB design and assembly.

FR4 is a favored PCB material for its cost-effectiveness and versatility. However, its thickness tolerance impacts mechanical strength, thermal performance, and electrical efficiency, affecting overall PCB reliability and performance.

PCBs are essential for electronic devices, providing mechanical support and electrical connections. This article explores the importance of PCB panel dimensions, standard sizes, and optimization techniques. Key points include cost-efficiency, ease of manufacturing, quality control, and optimal layouts. Factors like board size, volume needs, and equipment capabilities influence panel size. Coordination with manufacturers, using design software, and employing standard sizes can enhance production efficiency and quality.

PCB thickness is crucial in electronics, influencing performance, durability, and cost. The standard thickness is 1.57mm, but other sizes exist for specific needs. Factors like copper thickness, material choice, layers, and environmental conditions determine suitability. Custom thicknesses cater to high-power, space-limited, and high-frequency applications but may increase cost and production time. PCBX offers various thickness options, emphasizing quality and customer service in PCB manufacturing.