PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

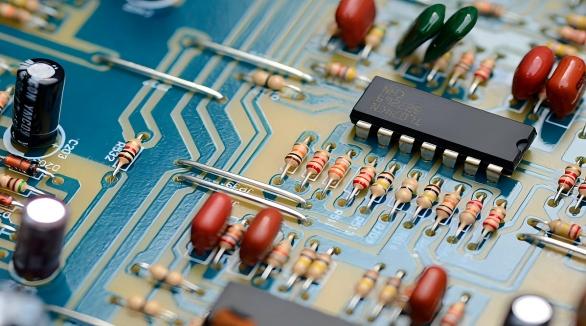

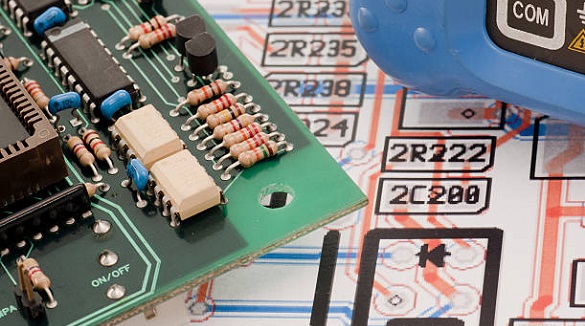

Understanding resistor power ratings in PCB design is crucial for ensuring circuit reliability, thermal efficiency, and preventing overheating through strategic layout and derating.

Optimize PCB layout for manufacturability by ensuring proper trace clearance, via placement, and incorporating testability features, while considering manufacturing tolerances.

In PCB manufacturing, DFM Checks ensure efficient production by identifying design issues early, reducing costs, enhancing quality, and preventing delays.

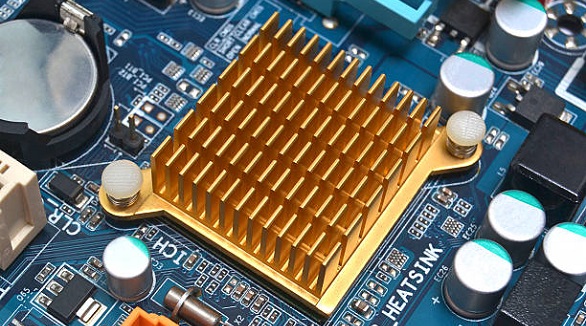

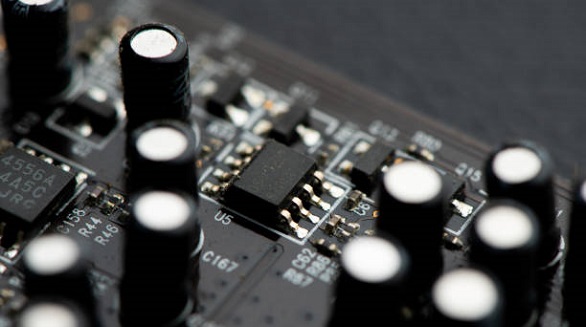

Heat sinks are essential for reliable PCB design, managing heat in high-density components like transistors and LEDs, ensuring optimal performance.

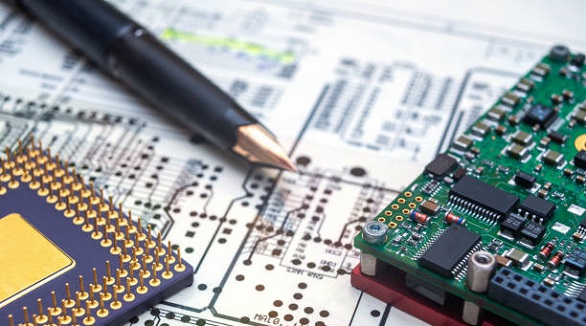

PCB design demands precision, using subcircuits for optimized layout, managing thermal concerns, and minimizing signal paths to ensure performance and manufacturability.

Voltage regulator PCBs ensure stable electronic device operation, offering solutions like linear and switching regulators for efficiency and reliability in designs.

Diodes, basic yet essential, control current flow in circuits and are key in PCB design, aiding rectification, signal detection, and voltage regulation.

Edge connector bevelling enhances PCB durability and reliable connections, vital for frequent usage and secure engagements, with limitations primarily in plating.