PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

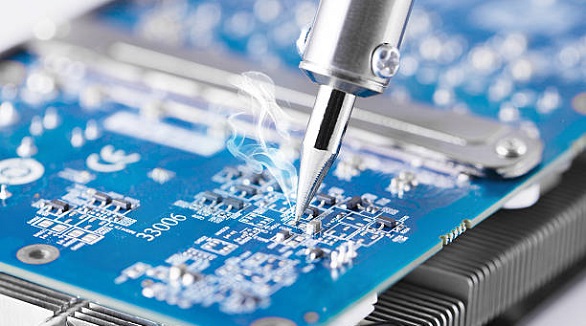

Selecting the right solder wire, with consideration for composition, flux type, and diameter, is crucial for creating reliable electronic connections in both hobbyist and professional settings.

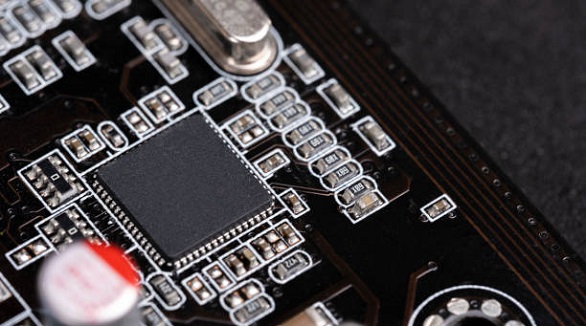

Choosing between clean and no-clean flux impacts PCB assembly efficiency and reliability. Clean flux suits high-stakes scenarios; no-clean excels in mass production.

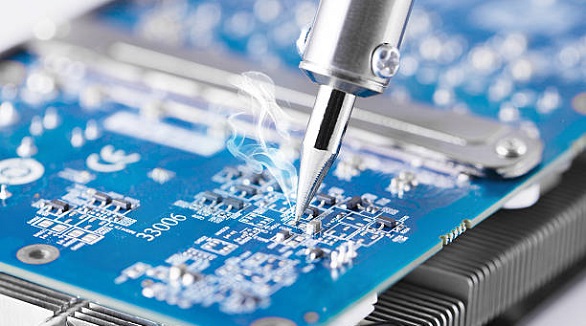

PTH soldering provides strong connections by threading component leads through PCB holes, requiring meticulous preparation and quality checks for lasting results.

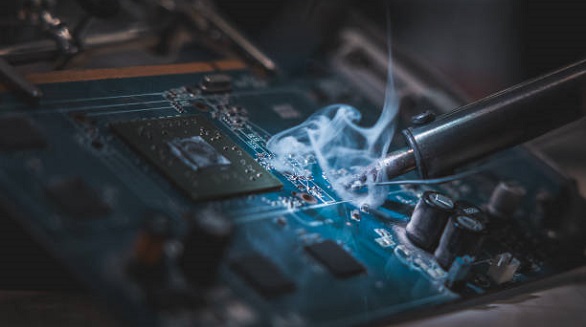

Dry solder joints in PCBs cause unreliable connections, leading to device failure. Prevent with proper heat, cleaning, quality solder, and skilled techniques.

Explore solder selection for circuit boards: understand types, best brands, and safety tips to ensure strong, reliable connections and optimal performance.

Wetting in soldering is crucial for strong PCB bonds, ensuring durability and conductivity. Address challenges like non-wetting by optimizing materials and processes.

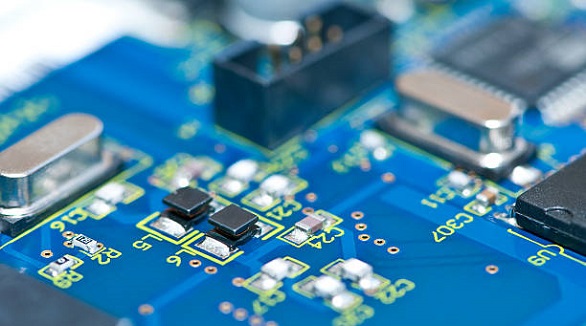

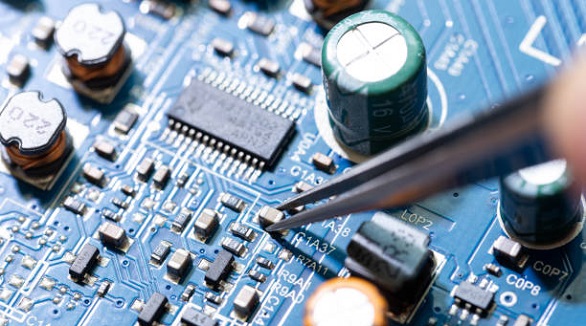

Master soldering chip components on PCBs using proper tools and techniques, ensuring precision and reliability for both hobbyists and professionals in electronics.

Solder flux ensures strong PCB joints by cleaning oxidation. Types include rosin, no-clean, and water-soluble, crucial for reliable electronics assembly.