PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

Proper trace-to-pad clearance in PCB design ensures safety, signal integrity, manufacturability, and longevity, following standards like IPC 2221 for optimal performance.

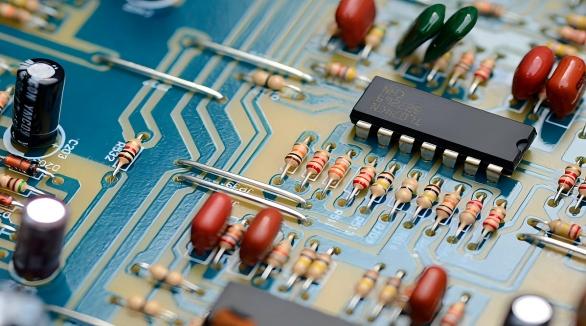

Understanding resistor power ratings in PCB design is crucial for ensuring circuit reliability, thermal efficiency, and preventing overheating through strategic layout and derating.

Signal reflection and distortion, resulting from impedance mismatches, impact PCB performance and require strategic design, simulation, and material selection for mitigation.

Copper weight determines PCB effectiveness in conductivity, thermal management, and mechanical strength, essential for high performance in various applications.

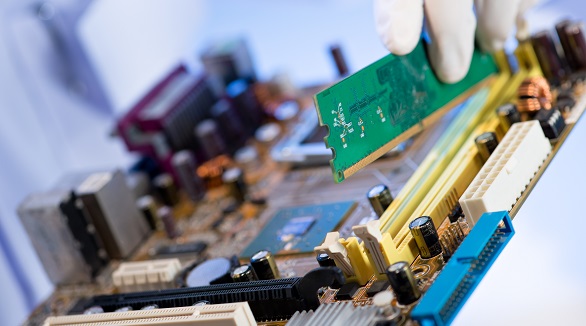

Optimize PCB layout for manufacturability by ensuring proper trace clearance, via placement, and incorporating testability features, while considering manufacturing tolerances.

In PCB manufacturing, DFM Checks ensure efficient production by identifying design issues early, reducing costs, enhancing quality, and preventing delays.

FR4 permittivity affects PCB signal speed and impedance. It's crucial for design, requiring careful management in high-frequency applications for reliability.

Nets in PCB design ensure logical connections from schematics to layout, enabling connectivity checks, design validation, and optimized manufacturing processes.