PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

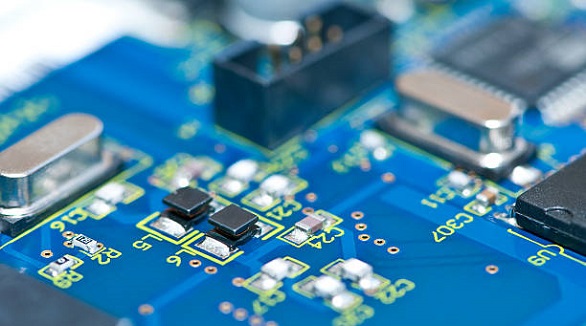

PCB assembly lines turn bare PCBs into functional electronics through automated soldering, precise component placement, inspection, and testing processes.

Common PCB assembly defects, their root causes, and proven prevention methods are outlined to improve reliability, yield, and manufacturing efficiency.

Choosing the right dielectric material for aluminum PCBs ensures effective thermal management, insulation, and reliability in high-power applications like LED lighting and vehicles.

Choosing between clean and no-clean flux impacts PCB assembly efficiency and reliability. Clean flux suits high-stakes scenarios; no-clean excels in mass production.

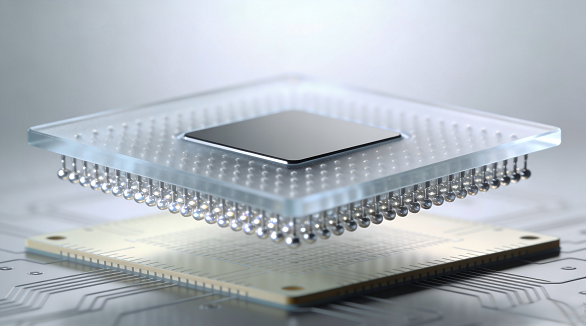

BGAs offer high-density interconnects and compact design, crucial for advanced electronics, but hidden solder joints complicate assembly, requiring precise methodologies.

PCB failures due to minor orientation and polarity errors can impact reliability, but proper design practices and checks ensure manufacturability and performance.

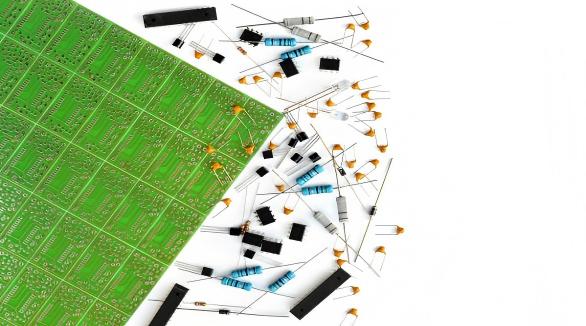

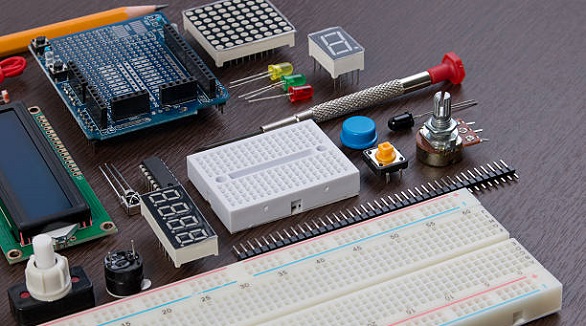

Prototyping in electronics uses stripboards for low-cost durability, perfboards for flexible custom layouts, and breadboards for quick, reusable testing setups.

EMI protection in PCB manufacturing ensures device reliability and compliance by using shielding, design optimization, and filtering to mitigate electromagnetic interference.