PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

PCB copper plating deposits conductive copper layers on PCBs, forming traces, vias, and through-holes that enable signal transmission, power flow, and reliable multilayer connections.

Copper wrap plating enhances PCB reliability and performance by strengthening connections, reducing thermal stress, and meeting industry standards like IPC 6012E.

Copper weight determines PCB effectiveness in conductivity, thermal management, and mechanical strength, essential for high performance in various applications.

Copper balance is key in PCB fabrication, ensuring signal integrity, thermal management, and reliability by managing copper distribution for efficiency.

Dry solder joints in PCBs cause unreliable connections, leading to device failure. Prevent with proper heat, cleaning, quality solder, and skilled techniques.

Aluminum PCBs excel in thermal management and mechanical strength for high-performance uses, but FR4 offers better electrical insulation and lower cost.

Reduce PCB noise for reliable analog signals with organized design, strategic layout, component selection, and targeted noise management techniques to enhance performance.

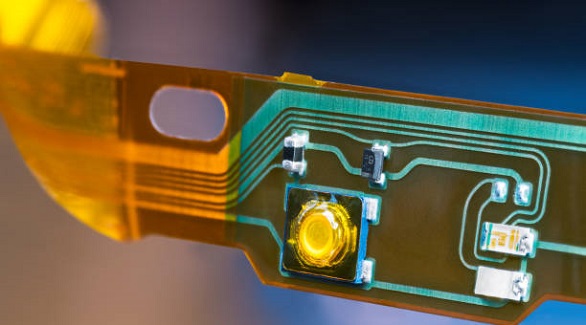

Flex PCB thickness affects performance, offering flexibility, compact design, and durability but demands careful material selection and precise engineering.