Clean Flux vs. No-Clean Flux in PCB Assembly

Choosing between clean and no-clean flux impacts PCB assembly efficiency and reliability. Clean flux suits high-stakes scenarios; no-clean excels in mass production.

In the complex landscape of Printed Circuit Board (PCB) assembly, flux is not just a soldering assistant but a critical factor in defining electronic connections functionality. The distinction between clean flux and no clean flux has very important implications for the manufacturing stage as well as for the resultant functionality during the product usage stage. This detailed guide endeavors to articulate basic distinctions, benefits, and other key aspects associated with clean flux and no clean flux categories to ensure that the manufacturer wielding the knowledge is positioned to make an informed choice for the task at hand.

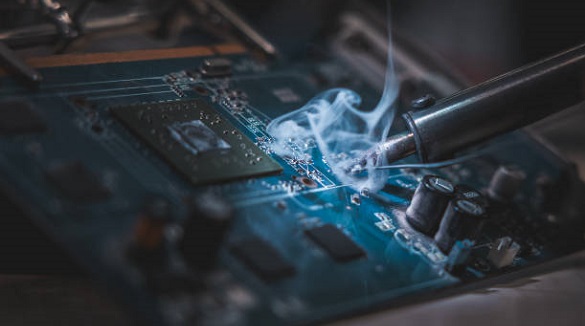

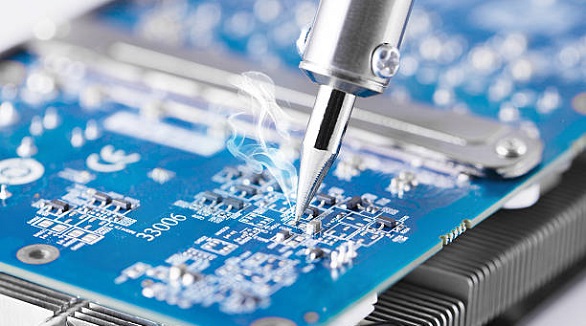

Understanding Flux: Its Core Purposes

Flux is a crucial entity in the world of soldering because of the following reasons:

Oxide Removal: Metallic surfaces always develop layers of oxide that prevent solder from adhering well to those surfaces. Flux helps remove these oxide layers to promote bonding between solder and other metallic surfaces.

Prevention of Re-Oxidation: When soldering, the flux buildup prevents re-oxidation of and protects the cleaned surfaces from re-forming the oxide layer that could degrade their ability.

Wetting Facilitation: Flux reduces surface tension, thereby ensuring that molten solder firmly adheres to the surfaces that need to be bonded.

Residue Management: There are flux residues that need to be removed after soldering. These may cause electrical, mechanical, and cosmetic problems within the board or device.

Types of Flux Chemistry

The fluxes are made from various components, and this affects their properties, cleaning ability, and usage:

Rosin (RA) Flux: These are weakly active, and their residues are noncorrosive but undesirable. These are obtained from natural rosin.

Organic Acid (OA) Flux: A combination of synthetic acids, this flux has moderate activity and requires post-solder cleaning because it may leave corrosive residue.

Inorganic Acid (IA) Flux: Such fluxes are highly active, with the use of strong mineral acids, and are always coupled with cleaning, owing to corrosivity.

Water-Soluble (WS) Fluxes: They are medium-active fluxes having water-soluble residues, which can be removed through easy water washes after solder

No-Clean (NC) Flux: Made from mild organic activators to create low-residue substances that won't corrode and do not require cleaning if properly processed.

Clean Flux

Characteristics and Benefits:

Activity Levels: The clean flux supports a set of activities that go from light (RA) through highly active (IA), to handle different degrees of oxidation and contamination.

Residue Concerns: The residues created by clean fluxes range from corrosive to conductive and, therefore, Callahan proposes the removal of the residue entirely.

Cleaning Requirement: Post-soldering cleaning must be performed by using solvents or cleaning systems to remove any residues of flux.

Application Recommendations:

Match Chemistry to Application: Choose a flux that has activity corresponding to the oxidation level of the materials being processed.

Precision Application: Utilize automated systems for even application, with emphasis on applying minimal amounts necessary for efficient soldering.

Effective Cleaning: Cleaning the board after soldering goes a long way in making the board reliable. It also complies with the regulatory requirements and environment considerations.

No-Clean Flux

Characteristics and Benefits:

Low Residue Content: This flux is no-clean, having 1-5% residue content by weight. Hence, it leaves little or no residues, so the post-soldering process is easier.

Mild Activators: These fluxes use mild organics, thus minimizing reactive residues that can significantly reduce the risk of corrosion and short circuits.

Process Efficiency: Elimination of the cleaning step reduces time and production costs, providing a smooth workflow that is very suitable for high-volume applications.

Application Suggestions:

Precise Application: Ensure to measure precisely to apply only those amounts of flux that are necessary for the job at hand, thereby minimizing unnecessary residues.

Tight Process Control: Stringent control of soldering parameters to maximize flux performance and eradicate latent reliability risks.

Follow-up on solder: scheduling assemblies for routine examination and testing in service to guarantee that no-clean residues will not result in performance compromise over time.

Reliability Issues

Although no-clean fluxes do away with the cleaning step and its expenses, they require careful attention to the subject of long-term futures:

Surface Insulation Resistance (SIR): It is essential that these residues exhibit high SIR to avoid any leakage of current.

Electrochemical Migration: There are minimal ion residues if dendrite formation is to be avoided. This results in electrical shorts.

Corrosion Risks: Even with no-clean flux, there can still be risks of degradation in materials, more so when the environmental conditions are tough.

The choice between clean and no-clean flux has a critical effect on both the processing speed and quality of the final electronics product. Clean flux is best used when there are demanding soldering processes or when residue removal is more precise and demanding, and added cleaning is required. No-clean flux is designed for consumer electronics, requiring maximum production efficiency as their first consideration, providing that control over the processes and reliabilities are maintained.

The area that demands high stakes, like military and space applications where reliability is not negotiable, still relies on traditional clean flux. In mass production for consumer products, on the other hand, no-clean flux is most preferred due to ease of processing and cost economics.

The final choice depends on an honest assessment of the operating context, cost factor, and reliability requirements, in order to see that the choice of flux type chimes in with broader performance requirements in terms of efficiency and effectiveness.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Wave soldering, crucial for assembling PCBs with through-hole components, remains vital for producing strong joints efficiently, despite SMT advances, by optimizing key parameters.

Solder flux ensures strong PCB joints by cleaning oxidation. Types include rosin, no-clean, and water-soluble, crucial for reliable electronics assembly.

Flux removal is essential for PCB reliability, preventing corrosion and supporting coatings, using isopropyl alcohol or other methods for high-quality manufacturing.