Functions and Types of PCB Plates in Electronics

PCB plates provide vital support and customization in keyboards, impacting stability, sound, and performance, underpinning electronic design and evolution.

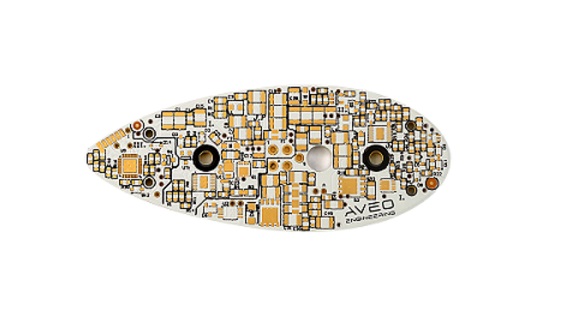

In electronic design and development, printed circuit boards (PCBs) are the core of the majority of digital products. They offer both mechanical and electrical infrastructures to ensure smooth functionality of electronic elements. In PCB structure, one of the essential though least noticed elements is the PCB plate. This component is pivotal in improving the board's functionality, longevity, and overall performance.

Roles of PCB Plates

PCB plates play numerous critical roles in electronic devices, particularly in keyboards:

Structural Support: Another one of the primary functions served by PCB plates is providing structural support for the PCB, establishing a solid base that reduces flexing and enhances durability. When utilized in keyboards, this structural reinforcement becomes crucial as it provides a firm surface for mounting keys and switches, preventing bending and enhancing its lifespan.

Electrical Pathways: PCB plates assist in creating efficient electrical pathways. The copper layers of the plates are etched such that various components are connected, allowing easy electronic communication. This is necessary to maintain the integrity and functionality of the circuit design.

Thermal Management: Electronic components have a tendency to produce heat during operation. PCN plates assist in thermal management as they efficiently dissipate heat, thus ensuring stability in performance and longevity of the electronics.

Aesthetic and Functional Customization: Beyond their technical functions, PCB plates can also be aesthetically customized, particularly in products like mechanical keyboards where user feel and taste are important.

The Unique Position of PCB Plates in Keyboards

In keyboard designing, PCB plates are unique particularly with their multiple functions ranging from supporting switches to defining the typing feel:

Plate-Mounted Switches: Mechanical keyboard switches are usually mounted on the PCB plate rather than directly on the PCB. The plate provides additional support and stability, which reduces key wobble and provides an ideal tactile feedback per key press.

Keyboard Sound and Stability: PCB plates contribute greatly to the sound profile of keyboards. Different materials provide different sound profiles and typing qualities, from resonant and solid to muted and soft.

Types of PCB Plates

Various materials are employed in PCB plate manufacturing, each with their own properties and advantages. Some of the most common types include:

Brass: Renowned for its stiffness and weight, brass plates give keyboards a high degree of feel and a unique acoustic characteristic. Brass tends to tarnish and oxidize as well, particularly if proper maintenance is not given. The sound signature is typically characterized as loud and bassy, which appeals to users that desire a more profound auditory response.

Carbon Fiber: Carbon fiber plates are light and robust and offer flexibility, leading to a bouncy typing experience. Carbon fiber is prized for its strength-to-weight ratio and is ideal for those who desire a responsive and dynamic typing experience.

Aluminum: One of the most widely used materials for PCB plates, aluminum is durable and inexpensive to manufacture. Aluminum is a well-balanced metal that is stiff and affordable and is therefore used extensively in custom keyboards and pre-assembled keyboards. Aluminum plates are noted to provide a stiffer typing sensation with minimal flex.

Polycarbonate: As a plastic material, polycarbonate plates offer flex and a softer, more bassy sound profile. They therefore tend to be best suited for those who need a softer typing touch and a quieter keyboard.

Applications of PCB Plates in Keyboards

PCB plates are key to bringing the functionality and usability of mechanical keyboards to the next level. They have an important role to play in larger keyboards, where more stability is typically required to accommodate the larger size and weight. In avoiding flex and key wobble, PCB plates improve the build strength, leading to a more reliable and satisfying typing experience.

Types of PCBs Used in Keyboards

It is essential to learn about the types of PCBs so that PCB plates can be effectively integrated into keyboards:

Through-Hole PCBs: In such PCBs, components are soldered by going through holes in the board, forming robust connections. Although here a PCB plate is not required, it can provide additional rigidity, highly worthwhile for skilled builders who prefer personalized builds.

Hot-Swappable PCBs: Hot-swap sockets are included in these PCBs, making it easy to swap switches without soldering. For beginners or users who like changing switches all the time, this is the perfect feature that makes customization simple and convenient.

Soldered PCBs: Widely utilized in bespoke mechanical keyboards, soldered PCBs require switches to be soldered permanently, yielding stable and secure key installations. They even support 5-pin switches, offering better connections and mechanically stable constructions.

PCB plates play a major role in designing and making electronic devices function, particularly when it comes to the mechanical keyboard. Their roles in structural reinforcement, electrical connection optimization, thermal output regulation, and material tailoring cannot be overstressed. To a hobbyist working on a custom keyboard or an engineer working on intricate circuits, the choice of PCB plate material and design will contribute immensely towards determining both the device's performance and the user experience. PCBX will still be offering important information and support, in order for designers and engineers to have the knowledge they need to make informed decisions in the creation of PCBs. With the future continuing to become more digital, diversification and innovation in the design of PCB plates will obviously be at the forefront of electronic solution development.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

In the fast-evolving electronics field, PCB performance hinges on dielectric material selection, crucial for signal integrity, thermal management, and reliability.

Select aluminum PCBs for excellent heat management or FR4 PCBs for cost-effective versatility in diverse electronic applications.

Aluminum PCBs are widely used electronic boards with comparatively better heat dissipation properties. The aluminum core cools down the components of the product, thereby improving its performance. These are eco-friendly, light, and strong PCBs and hence appropriate to be used in audio equipment, power supplies, and lighting products such as LED lighting.