PCBX.com Resources

Your source for industry knowledge, news, and expert insights

Latest Posts

Article

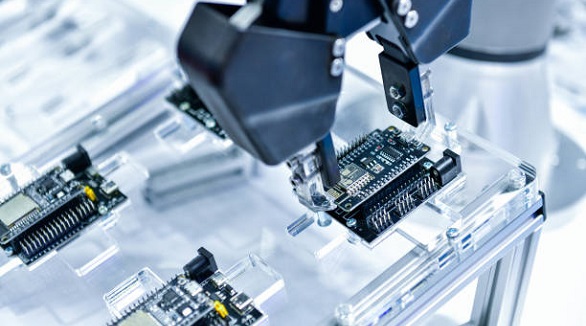

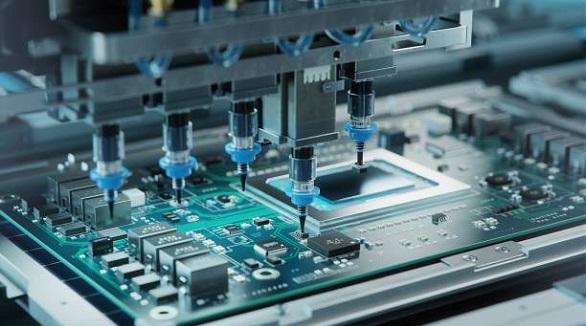

Automated PCB manufacturing enhances precision, reduces costs, and accelerates production, enabling efficient, high-quality mass production and customization, vital for industry advancement.

PCB plates provide vital support and customization in keyboards, impacting stability, sound, and performance, underpinning electronic design and evolution.

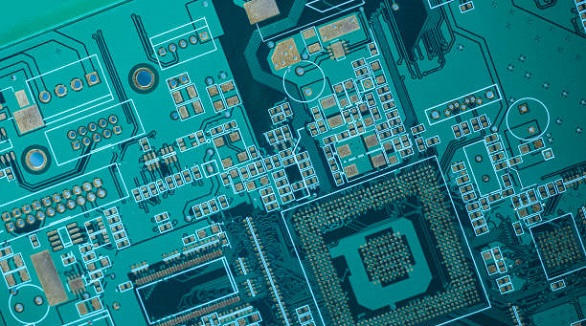

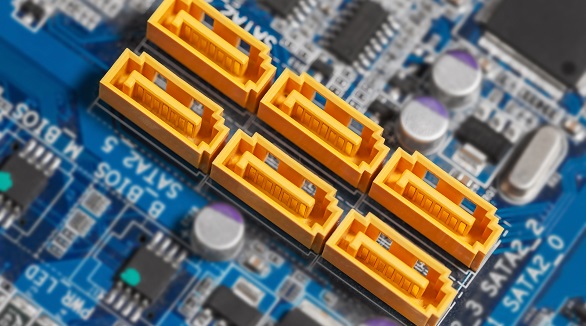

Choose the right PCB substrate based on application needs, balancing properties like Dk, Df, thermal conductivity, and cost, for optimal performance.

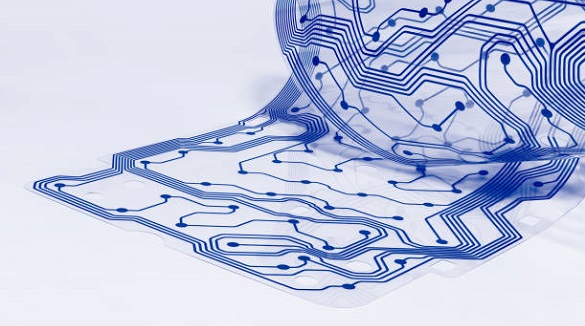

FPC stiffeners provide rigidity to prevent deformation, protecting components and ensuring reliability in flexible circuits used in electronics and wearables.

Ensure SMT quality through detailed design, supplier rigor, and process controls, enhanced by testing and continuous improvement for reliable, defect-free products.

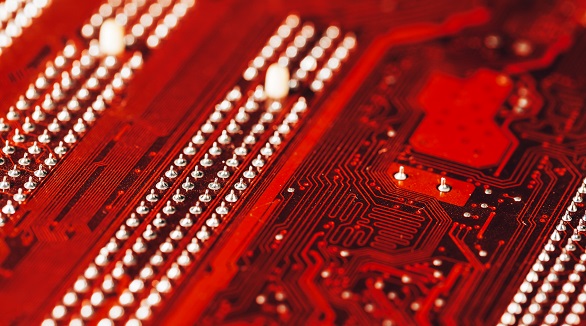

Red PCBs offer aesthetic and functional benefits like enhanced visibility and noise reduction, making them a versatile choice despite green's dominance.

SMA connectors are cost-effective for up to 18 GHz, while SMC excels beyond 26 GHz. Each suits different needs in RF/microwave applications, depending on budget and specs.

Universal PCBs provide flexible, cost-effective solutions for prototyping, enabling efficient development in electronics with diverse applications and easy adaptability.