How to Read Electrical Schematics?

Understanding electrical schematics is essential for electronics professionals, as it connects design, testing, and production processes, facilitating effective PCB implementation.

In the world of electronics, the ability to read and comprehend electrical schematics is a vital skill, crucial for professionals ranging from electricians to engineers, technicians, and even hobbyists. At PCBX, we understand the transformative power of adept schematic reading, not just for design and troubleshooting but as a foundational element in the fabrication and assembly of Printed Circuit Boards (PCBs). This article serves as a resource to guide you through the intricacies of schematic interpretation, enabling you to glean insights from block diagrams to complex circuit designs.

Understanding Electrical Schematics

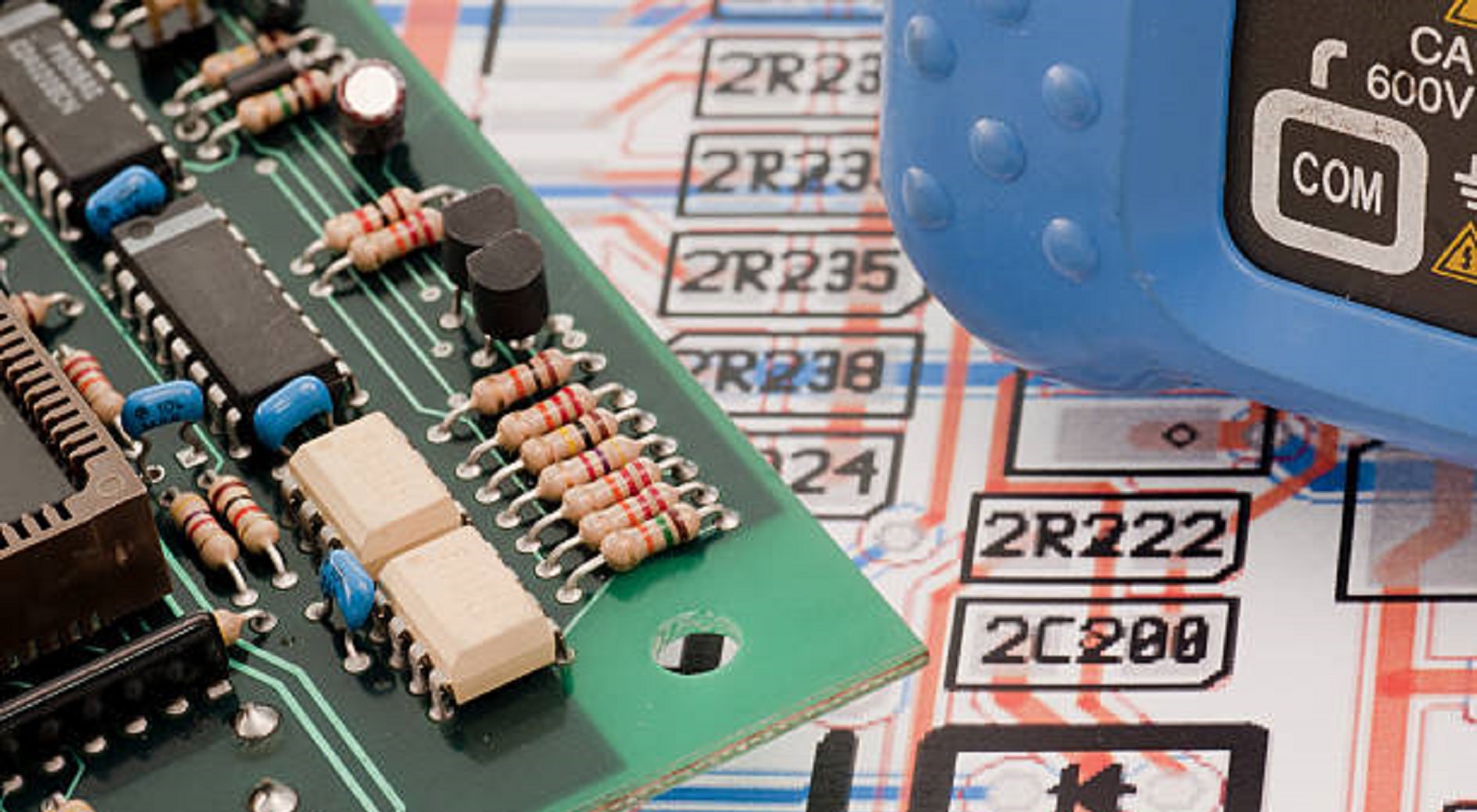

An electrical schematic is a detailed diagram that employs symbols to accurately represent the components and connections within an electrical or electronic circuit. These diagrams utilize standardized symbols to depict a circuit's components, lines to designate connections, and annotations to provide additional details. Whether you are involved in prototype assembly, system design, testing, or documentation, mastering schematics is indispensable.

Key Applications of Schematics

Schematics facilitate vital communications between design, manufacturing, and maintenance. Primary applications of schematics include:

Design and Engineering: Basic for PCB Fabrication, Prototyping, and System Design changes.

Testing and Troubleshooting: This guides the testing processes, including fault diagnosis during repairs.

Manufacturing/Production: Schematics serve as instructions for technicians on assembling, populating, and soldering PCBs.

Documentation: Supplies detailed performance specifications useful for maintenance and debugging.

Schematics, in essence, connect circuit designers, hardware assembly teams, repair and maintenance personnel, and even end-users.

Basic Symbols and Drawing Conventions

Before interpreting complex schematics, familiarize yourself with basic symbols and conventions that are universally adapted to:

Component Representation: Symbols are schematic representations and not exact physical representations. Example: a diode is represented as a triangle pointing to a line.

Polarity and Configuration: Indicate polarity on polarised components such as electrolytic capacitors and diodes with a cathode and anode.

Sizing and Alignment: The symbols are sized for clarity, not to scale, and aligned for readability, either horizontally or vertically.

Convention Standardization: Ensure the connections are clear and logical. Certain terms are also assigned to Power Rails such as Collector voltage (VCC), Drain Voltage (VDD).

Comfort with these symbols and conventions is the first step toward reading complete circuit schematics.

Tracing Current Flow and Connectivity

Schematics visualize how components connect to enable current flow, crucial to the function of an electrical system of any kind. Follow the guidelines:

Identify Power Sources: First, start tracing by looking for components such as battery symbols that indicate where power to the circuit originates.

Understand Current Paths: Understand how current flows through components, junctions, and stages.

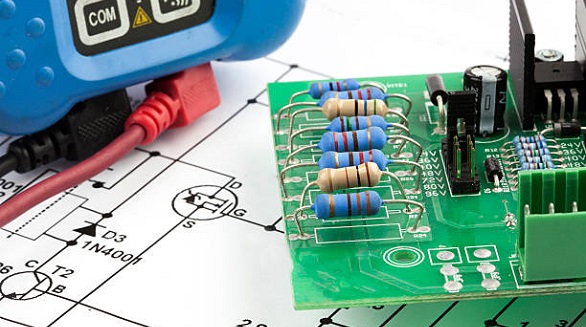

Let's consider a simple rectifier circuit as an example:

Power Source: Start with the AC source represented by a sine wave symbol

Transformers and Diodes: The transformer has current flowing through the primary winding; the diodes serve to rectify the AC signal from the secondary winding, while the capacitors smooth the output to deliver steady DC voltage.

Such stepwise tracing aids in comprehending not just simple circuits, but also more complex interconnected stages.

From Block Diagrams to Circuit Schematics

Adopt a step-wise learning approach starting with block diagrams:

Block Diagrams: Conceptualize an electronic system, dividing it into major groups. Example sections might include the tuner, video processing, and display of a TV.

Connectivity: Understand the flow of signals and powers between blocks to form the blueprint of the system.

Block diagrams give a high-level view, which is very important before moving to specifics of the circuit schematics.

Reading Power Supply Schematics

Power supplies are fundamental to electronic systems. Schematics of them can reveal valuable insights:

AC-DC Power Supplies: The schematics usually act as rectifiers that explain step-down transformation and voltage regulation.

Switch-Mode Power Supplies (SMPS): Smaller and more efficient, these use switched mode conversions with feedback loops to provide steady DC output.

Deducing power supply schematics trains one to create a basis for complex electronic systems independently.

Analog and Digital Circuit Interpretations

While digital technology may dominate, analog circuits remain integral; they are responsible for interfacing the real input/output world with a digital core.

Transistor Amplifiers: The configuration differs to obtain required amplification. Example: Common emitter amplifiers are crucial for the amplification of signals.

Operational Amplifiers (Op-Amps): Understand different feedback configurations for performing operations like amplification, integration, or filtering.

Working with these circuits develops intuitive insight.

Decoding Intricate Schematics

Schematics for the real world require layered understanding. Let's look at a switch mode battery charger:

Mapping Stages: High-frequency power conversion integrates voltage/current regulation and MCU control.

Servo Motor Drivers: Schematics show power regulation, signal generation with op-amps, and current sensing resistors.

Such interpretation provides insights into application-specific circuits.

Tips for Effective Schematic Reading

Contextual Clarity: Document circuit specifications.

Visual Grouping: Cluster related circuits and label functional stages.

Active Tracing: Follow flows cognitively using sketches or movements.

Review and Cross-Verify: Refer datasheets and rewind for better understanding.

Practice on a regular basis across a variety of schematics will build proficiency, supplemented by technical catalogs.

Future of Electrical Schematic

As systems evolve, so do schematics, combining with new technologies to create new and innovative design processes:

Simulation Models: These tools, like SPICE, emulate schematics to verify functionality.

Interactive Navigation: Graphs accommodate multiple-page schematic traversals.

Augmented views: Schematics layered on physical PCBs for a practical correlation.

The evolution includes integration with mechanical designs, cloud-hosted reviews, and AI for enhanced contextual assistance. The abilities related to electrical schematics anchor most of the design, manufacturing, and product support processes within the electronics industry. Acquiring this proficiency with the guidance of PCBX will easily enable any contributor to engineering feats-from conceptual designs to tangible product solutions. Whether in academic training or advanced production workshops, it is your capability to read and interpret schematics that forms the backbone of electronic innovation, opening up a world of possibilities for various applications and developments yet to come.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Current limit control circuits safeguard electronics by regulating excess current, ensuring device safety and reliability across various applications and industries.

Capacitors are crucial in PCB design for filtering and timing. Correct polarity in electrolytic and tantalum types prevents malfunctions and ensures reliability.

Edge connector bevelling enhances PCB durability and reliable connections, vital for frequent usage and secure engagements, with limitations primarily in plating.