Manual Assembly vs. Automated Assembly

Choosing between manual and automated PCB assembly depends on production volume, with manual assembly ideal for prototypes and automation best for high-volume runs.

The decision of automated PCB assembly or manual PCB assembly is one of the decisions that directly affects cost, quality, production efficiency and scalability in electronics manufacturing. At PCBX, we provide from hardware startups building prototypes to high-volume production. The assembly method selected at the beginning of a project can significantly influence its long-term success.

PCB Assembly in Product Reliability

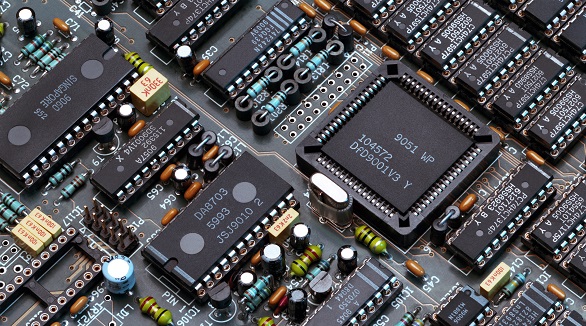

PCB assembly (PCBA) is the practice of assembling and soldering electronic parts onto a printed circuit board that has been manufactured to form a working device. The structural integrity is established by PCB fabrication; electrical performance, mechanical stability, and long-term reliability are established by the assembly process.

The assembly technique influences the production cost per unit, the rate of manufacturing, inspection and the capability to work with miniaturized parts. Choosing an inappropriate approach can result in higher costs, delays product releases, or reduce quality standards.

Manual PCB Assembly: Flexible and Ideal for Small Volumes

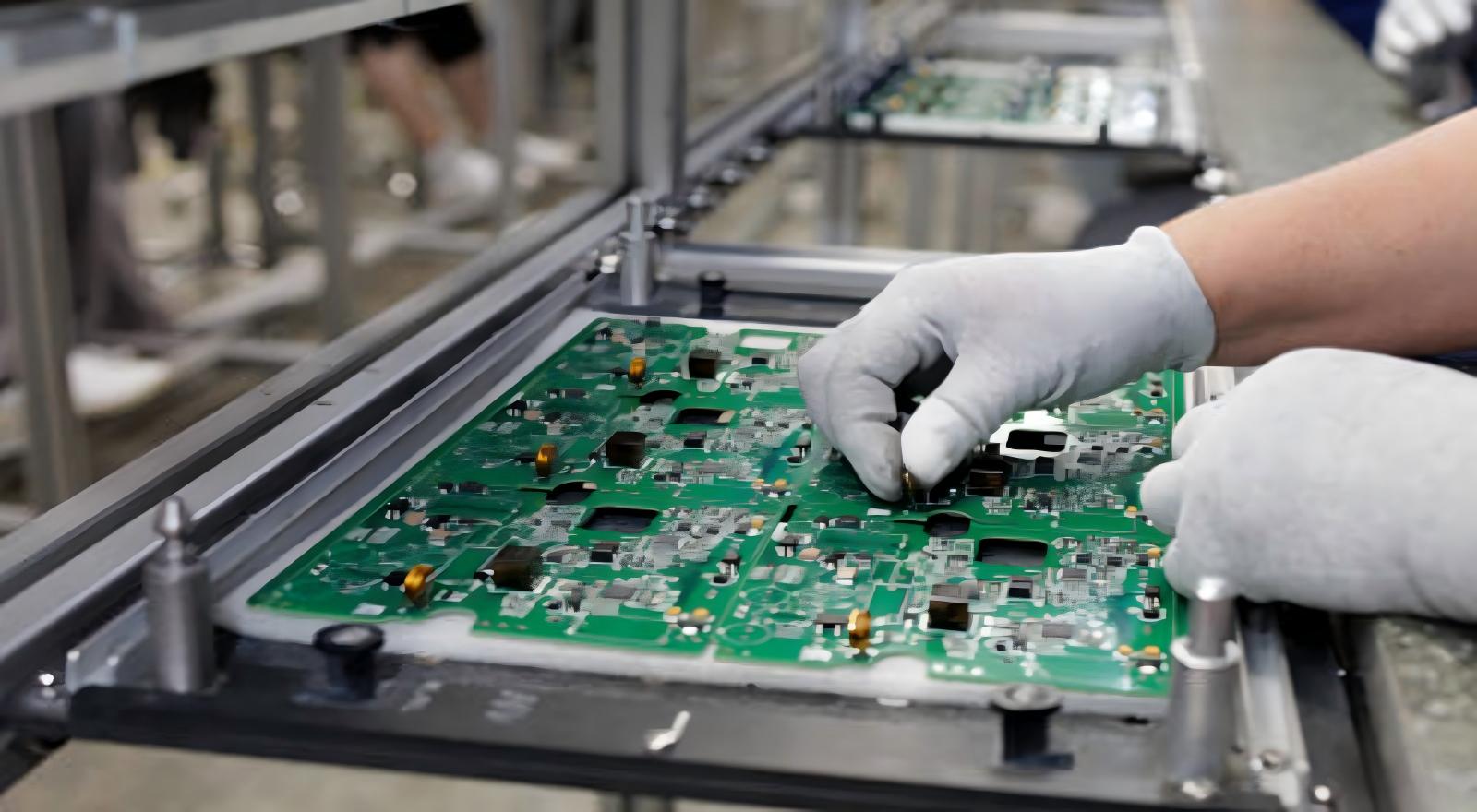

Manual PCB assembly depends on the work of technicians to place and solder components using soldering irons, hot air stations, microscopes, and precision hand tools. Even when automation has improved, manual assembly is still very useful where it is applied.

Its main advantage is flexibility. At prototyping stage and early product development, design modifications are common. Engineers can alter layouts, replace parts or experiment with different setups. Manual assembly also enables instant adjustments without rewriting the machine or creating additional stencils, and so, iteration is quicker and more cost-effective.

Minimal investment is also needed when assembling manually. The programmed automated production lines include programming, feeder set-up, stencil production, and calibration. In the case of small batch sizes, such fixed costs can overwhelm the efficiency benefits of automation. The cost of manual assembly eliminates these costs, which makes it economical with smaller production runs.

Large connectors, through-hole components, and some specialized parts can be more conveniently installed by hand in low quantities. Manual inspection is also significant to check connector alignment, inspect the quality of solder in difficult locations, and rework or repair.

But hand assembly is not without limitations. The rate of production is much less than automated placement systems and direct labor costs increase in direct proportion to volume. Inconsistencies like irregular solder joints or slight misalignments can be introduced by human fatigue and repetitive processes. Technicians who are experienced can produce high quality results but uniformity across large batches is difficult to achieve.

These reasons make hand assembly the best fit with prototypes, engineering validation builds, pilot production runs and low volume production where flexibility is of greater value than speed.

Automated PCB Assembly: Efficiency, Accuracy, and Scalability

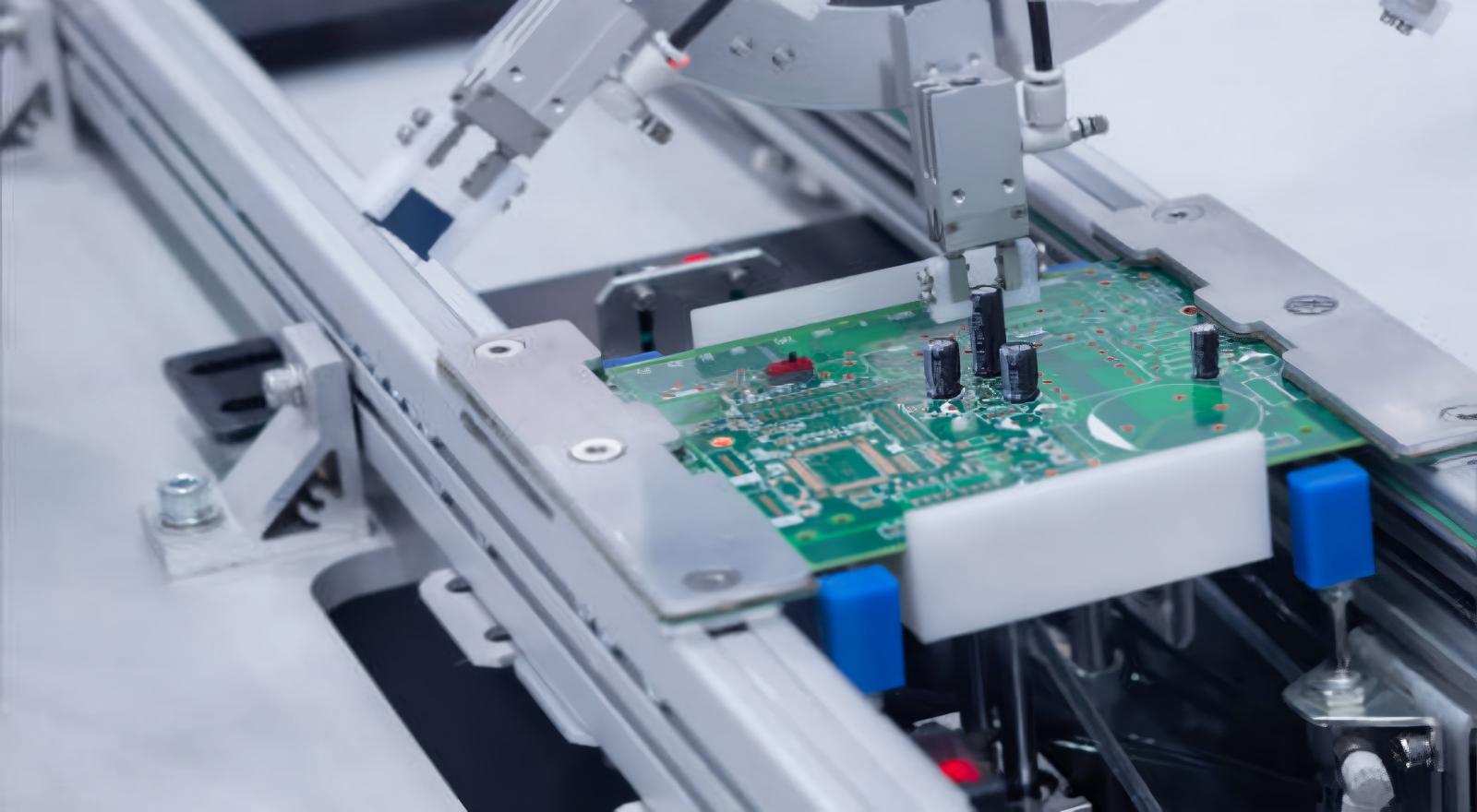

Computerized PCB production encompasses sophisticated manufacturing tools as solder paste printers, pick and place devices, reflow ovens, wave soldering systems and automated inspections. These systems are coded in such a way that they perform accurate and repeatable operations with minimal human intervention.

Speed of production is the greatest benefit of automation. Modern pick-and-place machines are capable of placing thousands of components in an hour, which is an enormous cut in manufacturing time. A reduction in the duration of production cycles can be a significant benefit in firms that have to compete in rapidly evolving markets.

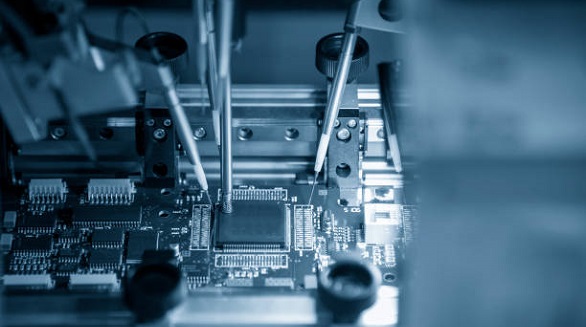

High precision and repeatability are also guaranteed through automation. Placement of the machine-controlled ensures proper alignment, and reflow profiles are optimized to give uniform solder joints. Such accuracy is necessary with small-pitch packages, BGAs, QFPs, and other small-size components that are not easily or at all hand-assembled.

Another significant advantage is quality control. Functional testing, in-circuit testing, automation of optical inspection (AOI) and X-ray inspection can greatly minimize defect rates. Automated assembly is used in industries like automotive, medical, aerospace, and industrial electronics in order to satisfy stringent regulatory and reliability requirements.

Automated assembly has lower start-up costs, but is more cost-effective with increasing volume of production. The fixed costs are spread out with larger amounts, reducing the per-unit cost. Automation in high-volume manufacturing saves a lot of money as opposed to the traditional labor-intensive processes.

The primary drawback of automation is lower flexibility when there is frequent design change. Engineering changes can involve reprogramming, new tooling, or process modifications, which can create a new time and cost burden. In the case of extremely low production runs, the initial investment might not pay off.

Volume as the Decision Factor of Production

The most determining factor in choosing an assembly process is usually based on the volume of production.

Manual assembly is frequently favored with prototypes and very small batches. It enables quick design reuse and escapes the set up costs of automated lines.

In low volume production, it depends on design stability and budget. When revisions are anticipated and quantities are also restricted, manual assembly can still be feasible. With rising volumes and design stability, partial/full automation starts to provide cost- and quality-benefits.

Automated assembly is usually the best option in the case of high-volume manufacturing. Its high speed, accuracy and built-in inspection makes it reliable in quality and affordable at large scale.

Hybrid Assembly: Combining Strengths

A hybrid approach is the most effective in most real-world projects. Automated placement can deal with standard surface-mount components effectively, whereas through-hole or special parts are inserted manually. Reliability is further improved through manual inspection and selective rework.

Hybrid assembly is mostly successful when the production volume is medium or when boards involve dense SMT layouts and unique components. This plan is cost-effective and flexible enough.

Strategic Considerations Beyond Cost

Although cost is a factor, other factors need to inform the decision. Design stability is another important factor; manual assembly is preferable in the face of frequent revisions, whereas automation is preferred with finalized designs. The size and density of components also play a role in the decision since typically a miniaturized package must be placed by an automated mechanism.

Time schedule requirements should be considered. Automated production capacity is typically required in large orders with short deadlines. Lastly, future growth prospects are important. When the first volumes are small but expected to grow fast, it is advisable to be associated with a manufacturer who can be able to do both to enable a seamless transition between prototype and a mass production.

Both manual and automated PCB assembly are vital in today's production of electronics. Manual assembly is flexible, has lower initial expenses, and is scalable to prototypes and small batches. Larger volumes of production are better served by automated assembly using superior speed, accuracy, scalability, and consistency.

The best option is determined by the scale of production, complexity of design, quality and future development. When you match your project goals with the assembly plan, you guarantee the effective production, the high quality of products work, and their competitive position in the market.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Circuit boards are essential for electronics but susceptible to failures; this guide details efficient diagnosis and repair techniques to ensure device reliability and safety.

SMT enables miniaturization in electronics manufacturing but presents defects that need identification and resolution to ensure product quality and efficiency.

PCBs enable miniaturization, efficiency, and cost-effectiveness in electronics. Automated assembly further reduces costs, enhances accuracy, speeds production, and ensures quality.