Mastering Professional PCB Cleaning

Professional PCB cleaning prevents corrosion and failure, typically using 99% IPA to safely remove flux residue while maintaining component integrity.

Throughout the perfection-oriented electronics production industry, the shift between a soldered assembly and a high-powered, finished product depends on a single, very important, and generally misunderstood factor: professional cleaning.

The Necessity of PCB Cleaning

PCBs are the brain of modern technology. In the assembly, they apply flux, which makes soldering easier, although chemical residue remains. This residue is usually hygroscopic or tends to be attracted towards moisture in the air. The presence of moisture with flux ions creates a conducting channel in which dendritic growth occurs, tiny metallic whiskers that microscopically bridge the traces and cause intermittent failures or permanent short circuits.

In addition to electrical failure, acids remaining can cause corrosion, eating away copper traces until the circuit is opened. Cleaning maintains signal integrity, avoids arcing in high-voltage boards, and permits protective conformal coatings to bond to the surface appropriately.

What is a Good Cleaning Solvent?

Solvents selection is not deciding which chemical is the strongest; it is about the right balance.

Effectiveness: Does it dissolve the particular flux chemistry (Rosin, No-Clean, or Organic) without leaving behind a film?

Material Compatibility: Will it melt the plastic of the connectors or strip the silkscreen?

Rate of Evaporation: A fast-evaporating solvent allows water to vapour off the board.

Safety: Does it comply with being non-toxic to the user and environmentally responsible?

Dielectric Strength: Does the solvent introduce any conductivity offset?

PCB Cleaning with IPA or Acetone

When engineers consider which solvent to use in cleaning PCB, they often discuss two heavy hitters. But their uses are very different.

Isopropyl Alcohol (IPA) - The Professional Standard

The electronics industry has no doubt the IPA is the go-to. It has to be 99% concentration to work. Less concentrated (such as 70% rubbing alcohol) has too much water, which may be trapped between components and can oxidize.

Pros: Light on most plastics, evaporates quickly, and very efficient with rosin-based fluxes.

Best Use: General removal of flux, finger oils, and board preparation before assembly.

The Riskier Alternative - Acetone

Acetone is a remarkably potent solvent, yet in PCB-land, power is hazardous. Although it is more aggressive than IPA, it dissolves tough residues.

The Risk: Acetone will dissolve many kinds of plastics used in headers, connectors, and even some varieties of PCB substrate binders. It can even peel away the protective solder mask or silkscreen legend off the board.

Best Use: It is only used in heavy-duty stripping off certain coats where the components are known to be acetone-safe. In 99 percent of PCB work, the safer, better option is IPA.

Safe PCB Cleaning Solvents

Deionized (DI) Water

In boards that accept water-soluble (organic) flux, DI water is an excellent water-soluble, non-toxic option. In contrast to tap water, which has minerals that leave conductive deposits (limestone/calcium), DI water is pure and leaves no residue.

Special Commercial Flux Removers

In industrial use, aerosol "flux removers" are designed to attack particular chemical bonds. These frequently include "High-Trigger" spray nozzles that deliver mechanical agitation to force flux out of under Low-Profile components.

Solvent Compatibility with PCB Components

The most important technical obstacle is compatibility. A solvent that cleans the copper perfectly may also melt the housing of a nearby capacitor.

Check the Datasheet: High-end parts (such as MEMS microphones or unsealed relays) frequently list solvent sensitivity.

The "Spot Testz": Prior to full-board wash, drop a small quantity of solvent on a non-critical portion of the PCB or a scrap component to determine whether it softened or discolored.

Plastics to Avoid: Use Polystyrene and Polycarbonate with added care, as these materials are especially prone to chemical crazing (micro-cracking).

Solvent Disposal and Safety Guidelines

Laboring with solvents means committing to environmental stewardship and safety.

Health Safety: Prefer working in a well-ventilated area. Dizziness or respiratory irritation may be induced by solvent vapors. Wear ESD-safe gloves so that the solvent does not strip your skin of its natural oils.

Disposal: Do not dispose of used IPA or acetone by draining. These fall under hazardous waste. Put used solvents in labeled, closed containers and call a local hazardous waste facility. Mishandling may cause environmental degradation and heavy penalties.

Fire Safety: IPA and Acetone are flammable. During the cleaning, make sure you do not have open flames or sparks (such as a soldering iron) in your workspace.

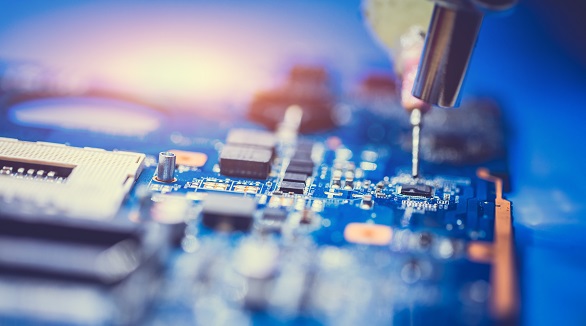

Professional Cleaning Process

De-energize: Make sure power is off and capacitors have discharged.

Dry Prep: Clean up loose dust or solder balls with a soft, ESD-safe brush.

Solvent Application: Lay down your preferred solvent (preferably 99% IPA) with a lint-free swab or brush.

Agitate and Rinse: Gently scrub. Very important: Clean the area with a new splash of solvent, not with dry flour.

Final Dry: Dry Surface Mount (SMD) components under the liquid with moisture-free compressed air.

Visual Inspection: Inspect with a magnifying lamp to rule out any residual white (partially dissolved flux) left behind.

Cleaning is the mark of good craftsman-work, as in the first solder joint as in the last use of the machine. Although IPA is the gold standard in terms of safety and efficacy, the sensitivity of solvent compatibility and disposal is what makes the amateurs professional.

Hot Tags:

Contact us

If you can't find what you're looking for, please contact us.

Article

Choosing between clean and no-clean flux impacts PCB assembly efficiency and reliability. Clean flux suits high-stakes scenarios; no-clean excels in mass production.

PCB recycling is vital to reduce environmental hazards and recover valuable materials, especially copper. Effective methods include mechanical, chemical, and thermal processes, significantly benefiting sustainability.

Printed Circuit Boards (PCBs) are crucial yet prone to corrosion, leading to malfunctions or failures. This article outlines detecting corrosion signs, preparing for cleaning, required materials, and step-by-step cleaning methods using isopropyl alcohol or alternatives. It also covers drying, reassembly, and preventive measures. Seek professional help if corrosion is severe.